High-speed board collecting and releasing machine with MES system and AGV vehicles

A kind of technology of unloading and triggering machine, applied in general control system, control/adjustment system, conveyor and other directions, can solve the problems of large floor space, untraceable, unable to realize automatic switching, etc., to reduce the floor space of equipment , Improve equipment efficiency, and eliminate the effect of manual input errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Those skilled in the art should recognize that this embodiment is only used to illustrate the present invention, rather than to limit the present invention, as long as the embodiments are changed and modified within the scope of the present invention, all can be used in the present invention within the scope of the claims.

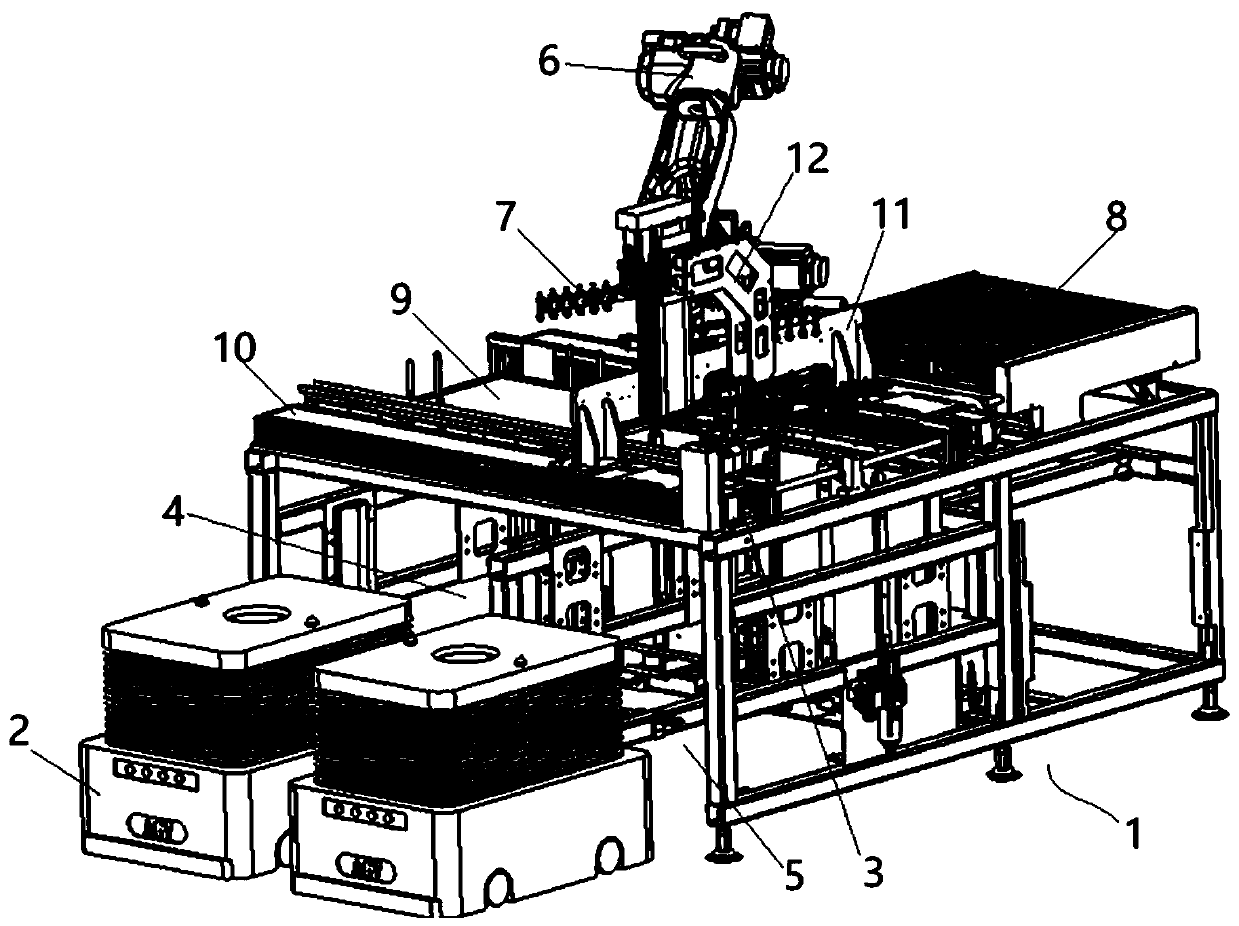

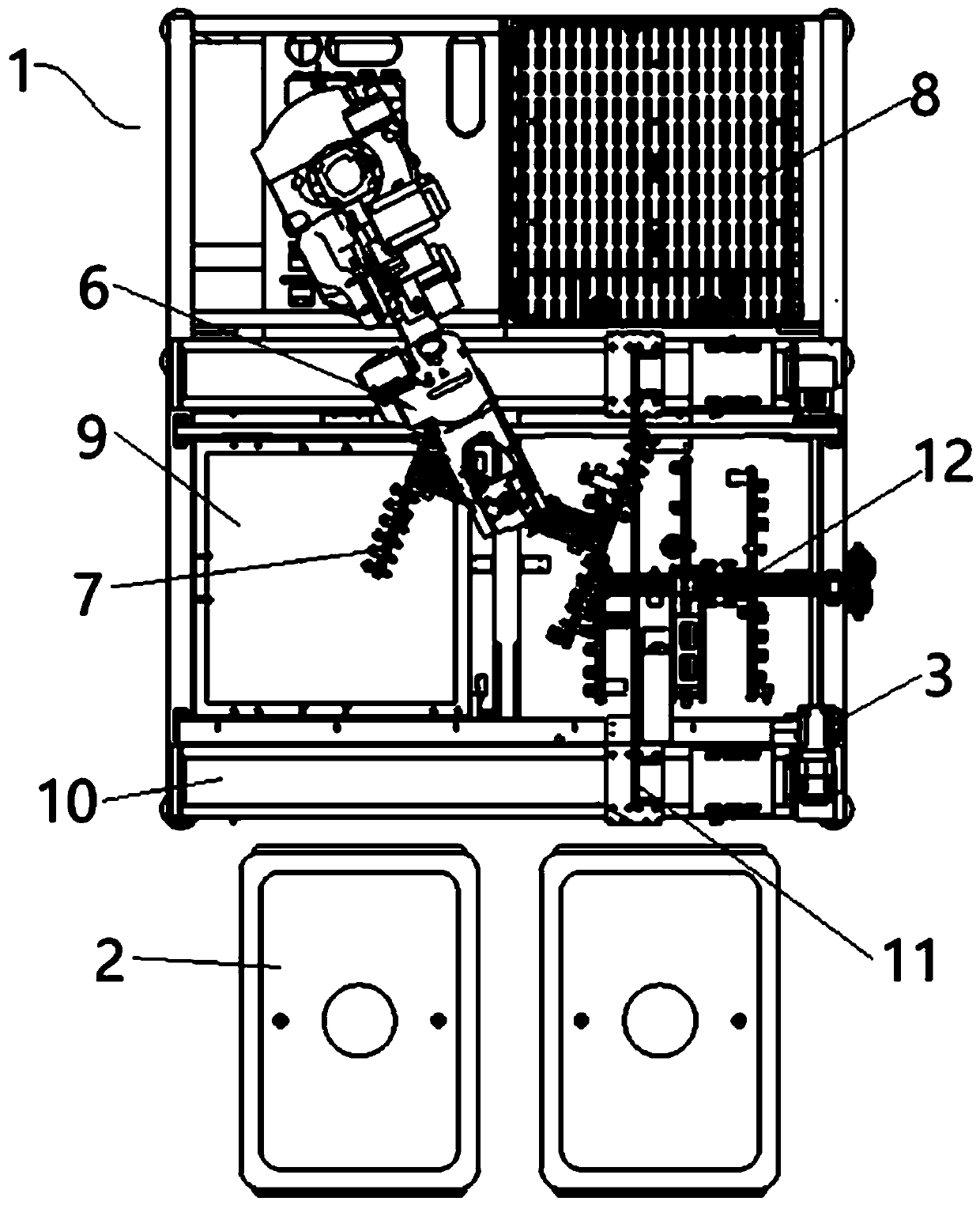

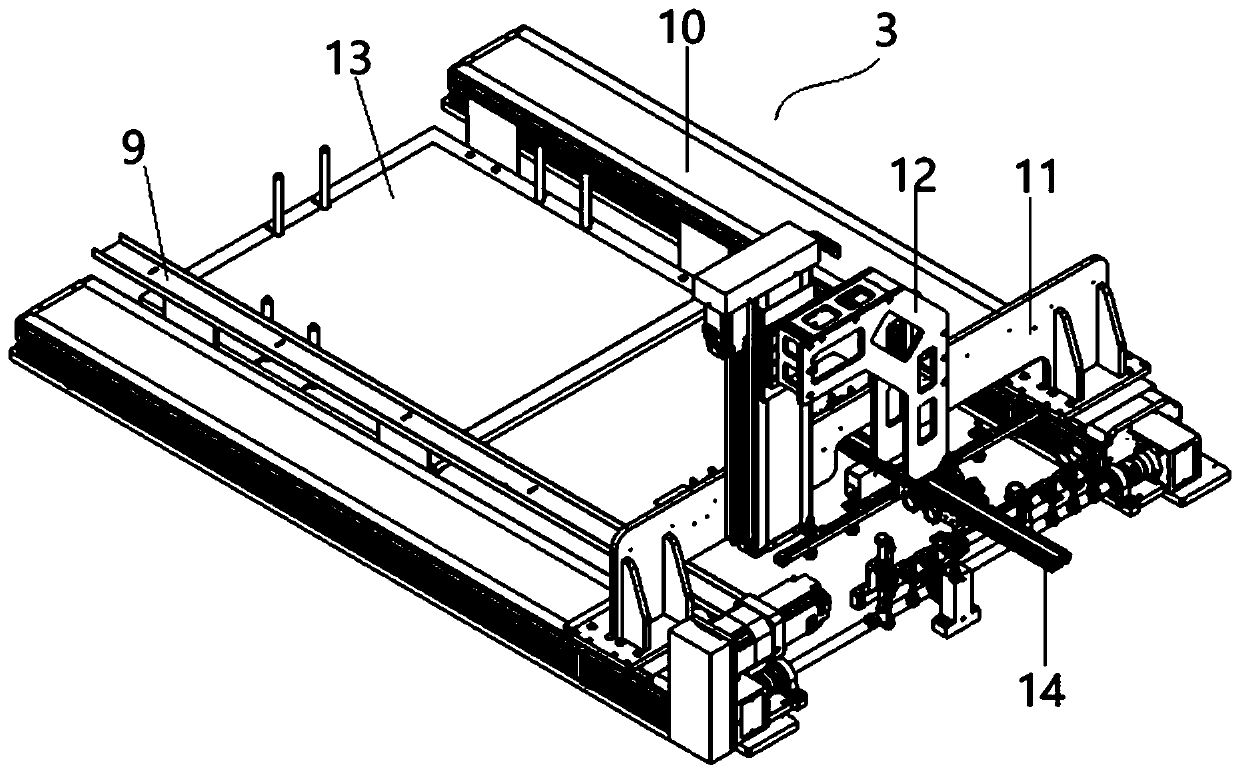

[0024] Such as Figure 1 to Figure 3 shown. A high-speed retractable trigger with an MES system and an AGV car, mainly comprising: a main body 1 of the trigger release machine and two AGV vehicles 2 arranged side by side; The paper platform switching mechanism 3 is used to perform operations such as grabbing the material board and moving the material board; the paper separation platform switching mechanism 3 includes two parallel horizontal guide rails 10, and the two ends are vertically erected on the horizontal guide rails 10 and can be Along the suction cup support frame 11 sliding back and forth, a suction cup group member 12 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com