an aluminum doped cr 2 o 3 High infrared reflective material and preparation method thereof

A technology of infrared reflection and aluminum doping, applied in the direction of chromium oxide/hydrate, etc., can solve the problems of high calcination temperature, difficult to mix materials evenly, etc., and achieve the effect of high infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

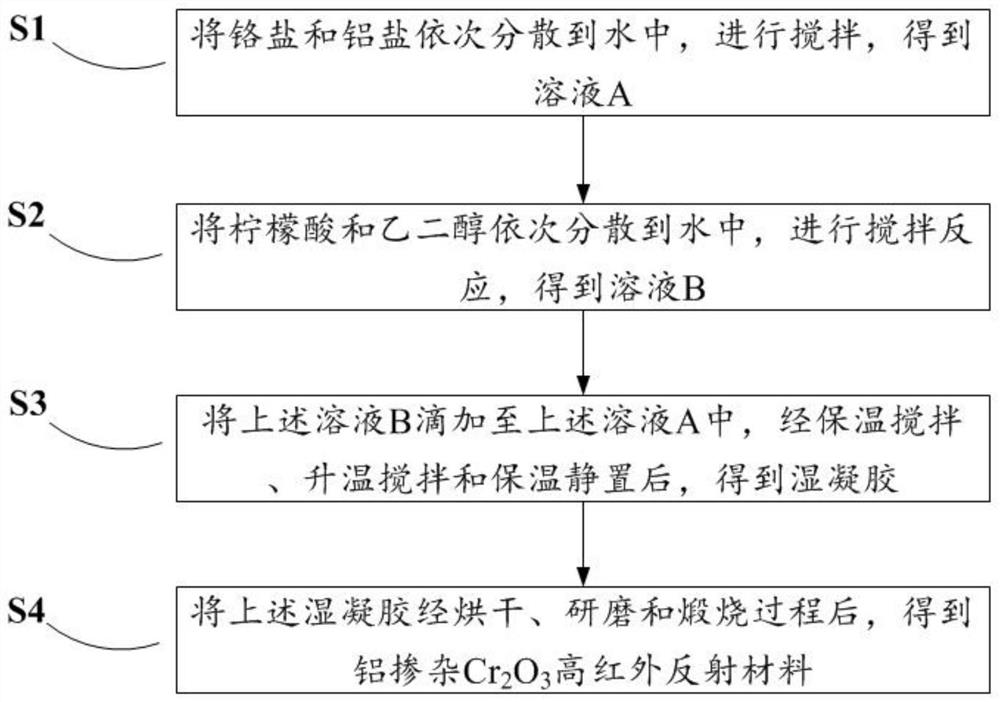

[0025] Such as figure 1 , figure 1 is the aluminum doped Cr provided by the present invention 2 o 3 A process flow diagram of an embodiment of a method for preparing a high infrared reflective material. For the first solution of the present invention, the present invention provides an aluminum-doped Cr 2 o 3 The preparation method of high infrared reflection material comprises the following steps:

[0026] Disperse the chromium salt and the aluminum salt in water in turn, and stir to obtain solution A;

[0027] Disperse citric acid and ethylene glycol in water in turn, and carry out stirring reaction to obtain solution B;

[0028] Add the above-mentioned solution B dropwise to the above-mentioned solution A, after heat preservation and stirring, heating and stirring, and heat preservation and standing, a wet gel is obtained;

[0029] After the above wet gel was dried, ground and calcined, the Al-doped Cr 2 o 3 Highly infrared reflective material.

[0030] In the pres...

Embodiment 1

[0049] Cr(NO 3 ) 3 9H 2 O(23.69g, 0.0592mol), Al(NO 3 ) 3 9H 2 O (6.66g, 0.0177mol) was added into 35ml of deionized water, and stirred at 60°C for 1.5h to obtain solution A;

[0050] Will C 6 h 8 o 7 ·H 2 Add O (16.1963g, 0.0769mol), ethylene glycol (7.17ml, 0.1155mol) into 10ml deionized water, stir at room temperature for 1.5h, and obtain solution B;

[0051] Add solution B dropwise to solution A with a dropper, and continue to stir at 60°C for 7 hours to form a sol, then raise the temperature to 80°C under stirring conditions, and keep it for 1.5 hours to obtain a wet gel;

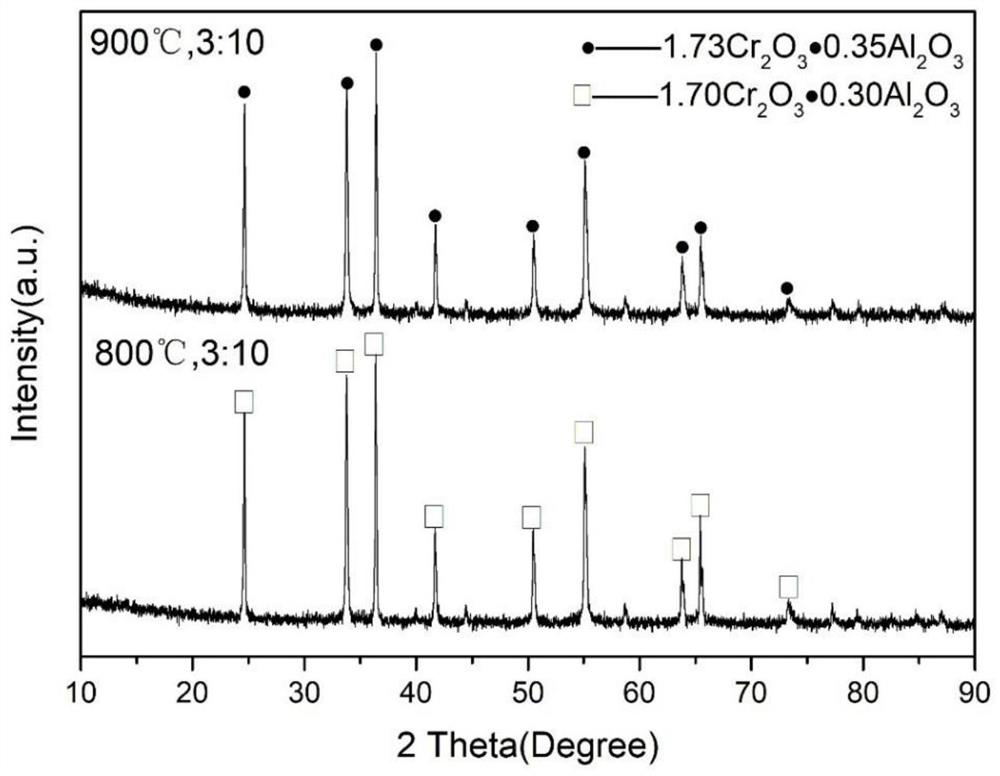

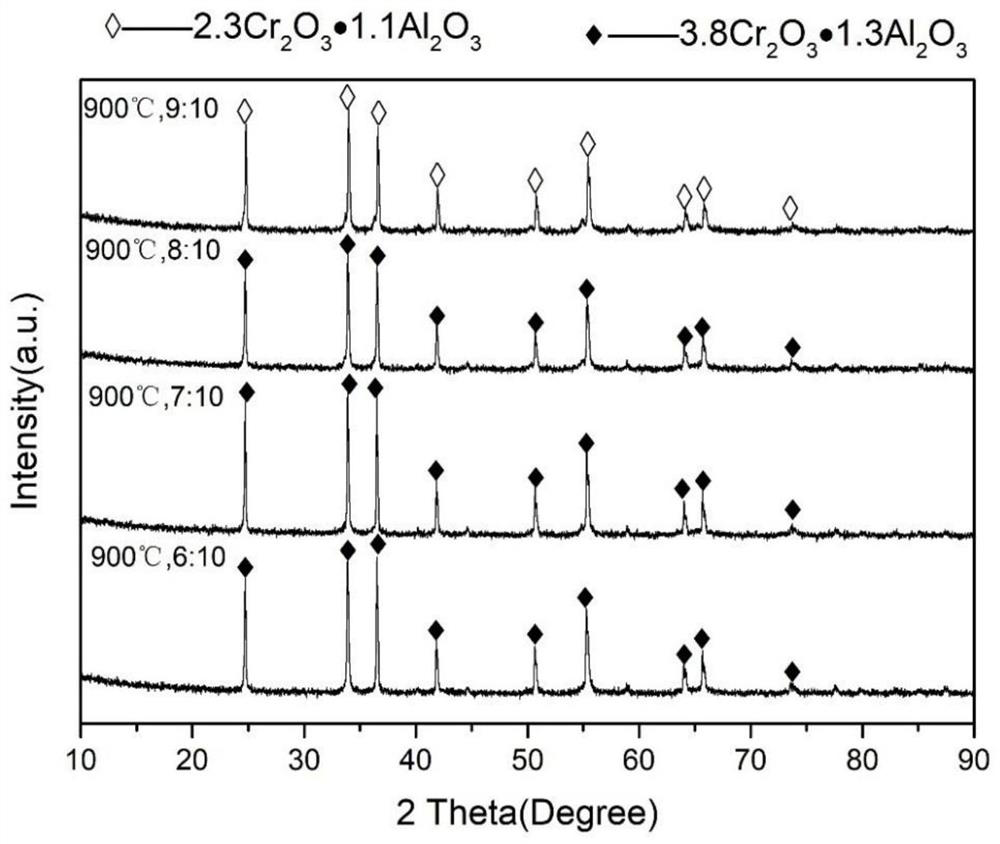

[0052] Take the wet gel out and put it in an oven at 70°C, take it out after 4 days, grind it into precursor powder, put the precursor powder in a muffle furnace set at 800°C for calcination, and the heating rate is 8°C / min , the holding time is 4h, and the aluminum-doped Cr 2 o 3 Highly infrared reflective material. In this embodiment, the molar ratio of aluminum salt to chromium salt is ...

Embodiment 2

[0054] Cr(NO 3 ) 3 9H 2 O(23.69g, 0.0592mol), Al(NO 3 ) 3 9H 2 O (6.66g, 0.0177 mol) was added into 35ml of deionized water and stirred at 60°C for 1.5h to obtain solution A;

[0055] Will C 6 h 8 o 7 ·H 2 Add O (16.1963g, 0.0769mol), ethylene glycol (7.17ml, 0.1155mol) into 10ml deionized water, stir at room temperature for 1.5h, and obtain solution B;

[0056] Add solution B dropwise to solution A with a dropper, and continue to stir at 60°C for 7 hours to form a sol, then raise the temperature to 80°C under stirring conditions, and keep it for 1.5 hours to obtain a wet gel;

[0057] Take the wet gel out and put it in an oven at 70°C, take it out after 4 days, grind it into a precursor powder, put the precursor powder in a muffle furnace set at 900°C for calcination, and the heating rate is 8°C / min, The holding time is 4h, and the aluminum-doped Cr 2 o 3 Highly infrared reflective material. In this embodiment, the molar ratio of aluminum salt to chromium salt is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com