Polycarbonate lens for LED illumination and preparation method thereof

A technology of LED lighting and polycarbonate, applied in lighting and heating equipment, lighting devices, lighting device parts and other directions, can solve the problems of increasing molding difficulty, high product defect rate, light source light efficiency attenuation, etc. Anti-ultraviolet performance, increase the scattering and transmission of light, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

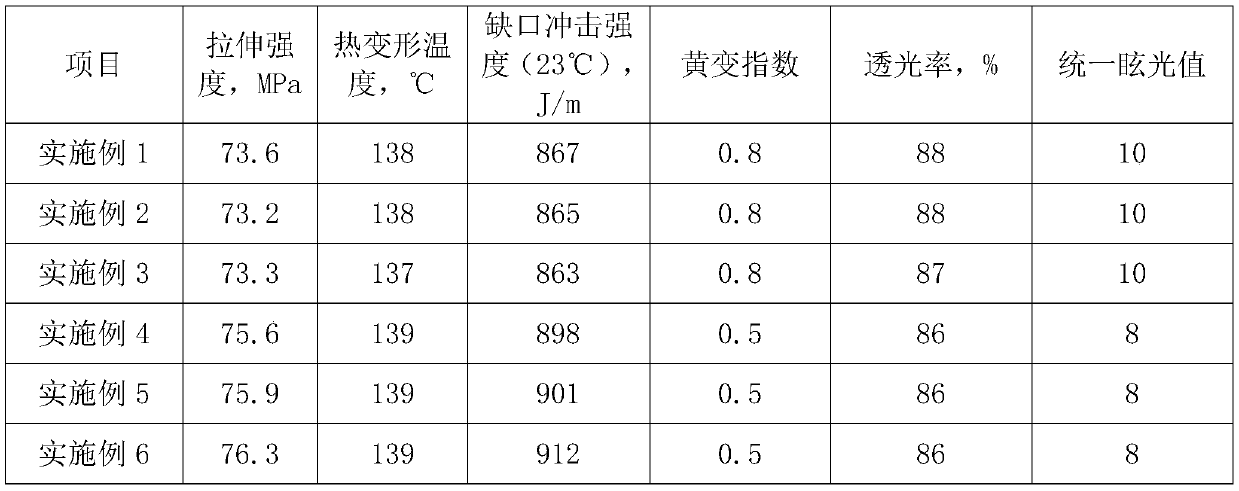

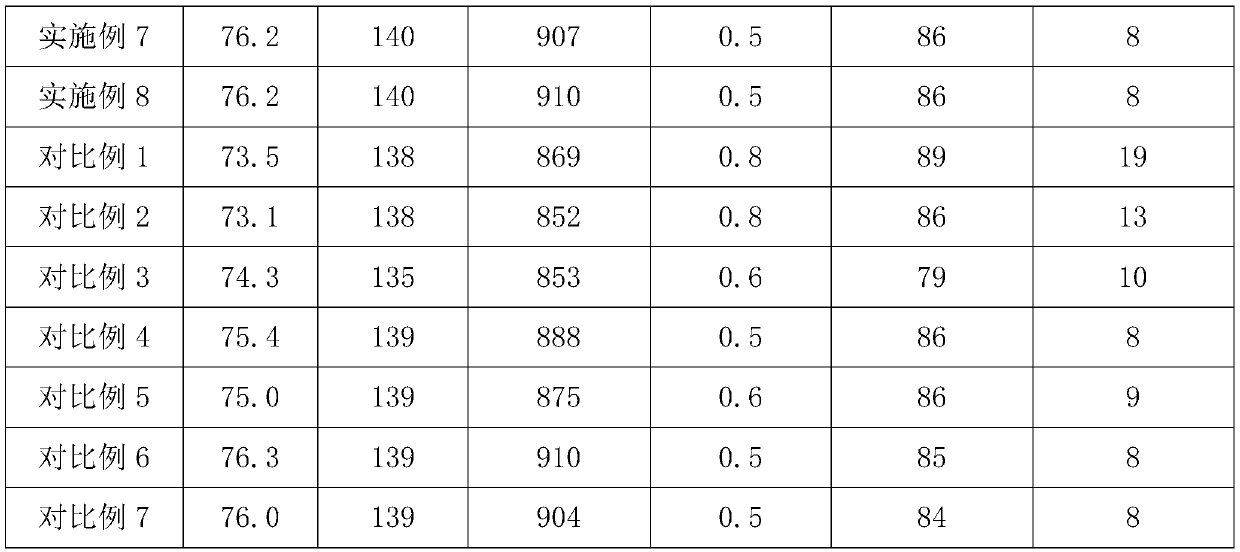

Examples

preparation example Construction

[0037] Preparation example of light diffusion masterbatch The silicone microspheres in the following preparation examples are selected from the type HY-690 silicone microspheres provided by Shenzhen Haiyang Powder Technology Co., Ltd.; the polycarbonate is selected from the grades provided by Idemitsu It is a polycarbonate resin of LC1500.

[0038] The light diffusion masterbatch adopts the following method: ① Take silicone microspheres, polydimethylsiloxane, and γ-aminopropyltriethoxysilane and mix them in a ratio of 90:10:1 to obtain a silicone mixture ②Take polycarbonate and silicone mixture, make it mix according to the ratio of 9:1, and melt blend at 270℃ for 5min to obtain silicone-polycarbonate mixture; ③Put silicone- After the polycarbonate mixture is sheared and crushed through a 200-mesh sieve, a light-diffusing masterbatch is obtained.

[0039] Preparation example of modified mica powder The mica powder in the following preparation examples is selected from the mic...

preparation example 1

[0040] Preparation example 1 of modified mica powder: a. Take mica powder and calcinate it at a temperature of 500° C. for 5 hours to obtain calcined mica powder;

[0041] b. Take lanthanum oxide, calcium acetate and water, mix according to the ratio of 1:2:50 by weight, and stir for 30min at a speed of 500r / min to obtain a suspension;

[0042] c. Add 1% of its weight of γ-(methacryloxy)propyltrimethoxysilane to the calcined mica powder, stir for 3 minutes, then add 40% of the weight of the calcined mica powder suspension for 30 minutes After all the drops are completed, the temperature is raised to 80°C, and stirred at a speed of 600r / min for 60min; then dried at a temperature of 150°C for 6h, cooled, crushed, and sieved to obtain modified mica powder.

preparation example 2

[0043] Preparation example 2 of modified mica powder: a. Take mica powder and calcinate it at a temperature of 500° C. for 5 hours to obtain calcined mica powder;

[0044] b. Take lanthanum oxide, calcium acetate and water, mix according to the ratio of 1:2:50 by weight, and stir for 30min at a speed of 500r / min to obtain a suspension;

[0045] c. Add 1.25% of the weight of γ-(methacryloyloxy)propyltrimethoxysilane to the calcined mica powder, stir for 3 minutes, then add 50% of the weight of the calcined mica powder suspension for 30 minutes After all the drops are completed, the temperature is raised to 85°C, and stirred at a speed of 800r / min for 75min; then dried at a temperature of 155°C for 7h, cooled, crushed, and sieved to obtain modified mica powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com