Preparation method of polyurethane laminating adhesive for lithium battery

A polyurethane and lithium battery technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as poor hydrolysis resistance, normal performance, and poor adhesion of metal composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

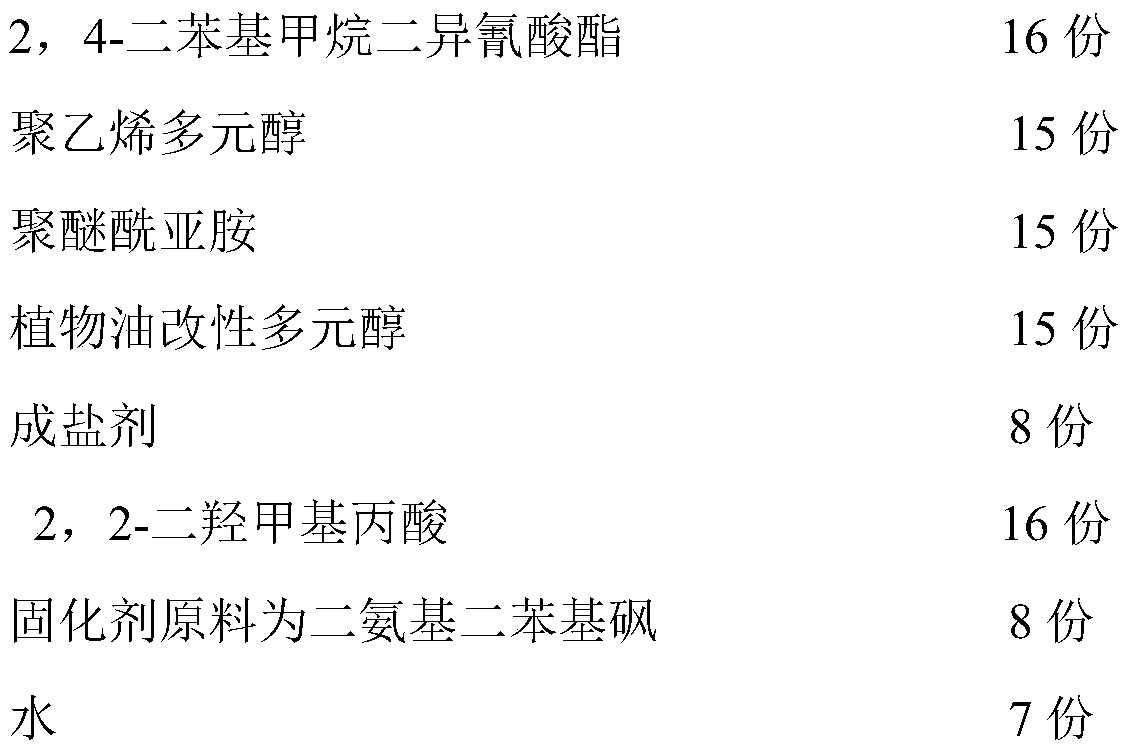

[0021] A preparation method of lithium battery polyurethane laminating adhesive, a main agent of lithium battery polyurethane laminating adhesive is mainly made of the following raw material components in mass ratio:

[0022]

[0023] Its specific preparation method is as follows:

[0024] 1). The synthesis of anionic water-soluble polyurethane, the synthesis of anionic water-soluble polyurethane, is to prepare NCO-terminal prepolymer by reacting polyethylene polyol and 2,4-diphenylmethane diisocyanate; then prepare NCO-terminal prepolymer The body uses 2,2-dimethylolpropionic acid to chain extend and end-block to synthesize a carboxyl-containing oligomer; finally, add the bottom polymer to the aqueous solution of the salt-forming agent for dispersion to obtain anionic water-soluble polyurethane. When preparing the prepolymer, according to the type of diisocyanate and polyetherimide selected, it should be added in proportion to the chemical formula, and it should be fully s...

Embodiment 2

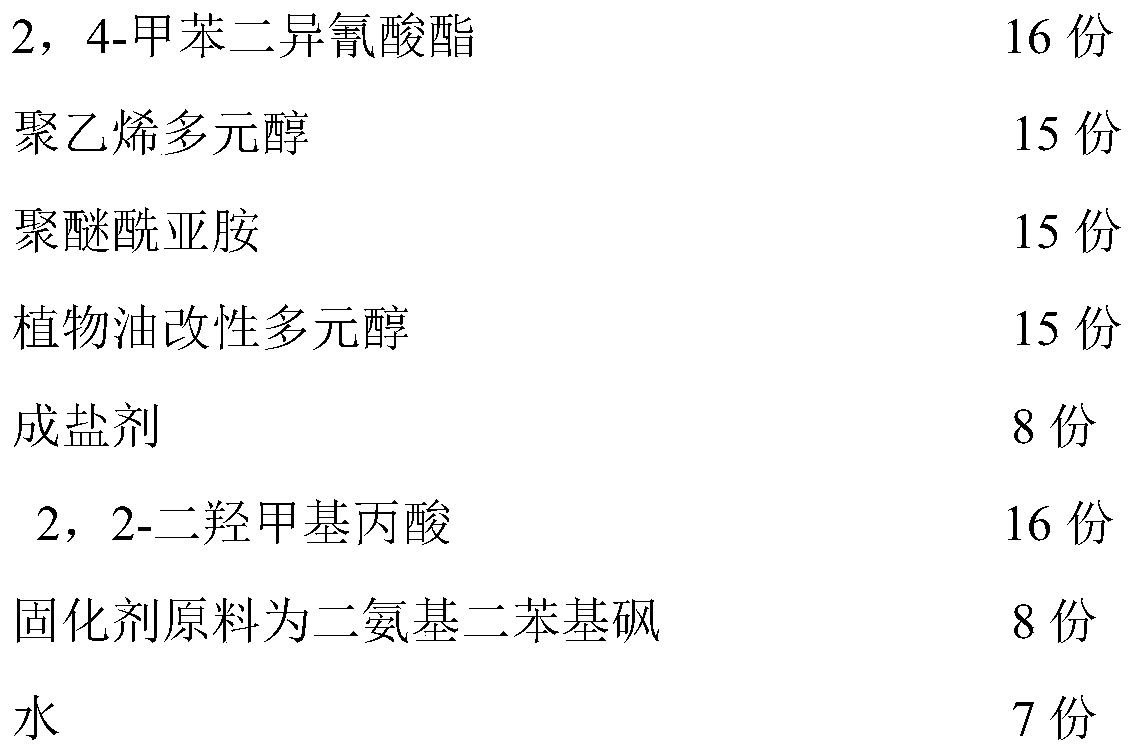

[0030] A preparation method of lithium battery polyurethane laminating adhesive, a main agent of lithium battery polyurethane laminating adhesive is mainly made of the following raw material components in mass ratio:

[0031]

[0032] Its specific preparation method is as follows:

[0033] 1). The synthesis of anionic water-soluble polyurethane, the synthesis of anionic water-soluble polyurethane, is to prepare NCO terminal prepolymer by reacting polyethylene polyol and 2,4-toluene diisocyanate; then make NCO terminal prepolymer with 2 , 2-Dimethylolpropionic acid chain extension and end-capping to synthesize oligomers containing carboxyl groups; finally, add the bottom polymer to the aqueous solution of the salt-forming agent for dispersion to obtain anionic water-soluble polyurethane. When preparing the prepolymer, according to the type of diisocyanate and polyetherimide selected, it should be added in proportion to the chemical formula, and it should be fully stirred withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com