Environment-friendly release agent for aerated bricks and preparation method thereof

A technology of release agent and aerated bricks, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of great harm to the human body and the environment, long preparation cycle, complicated process, etc., and achieve no material residue, good demoulding effect, Surface clean and tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

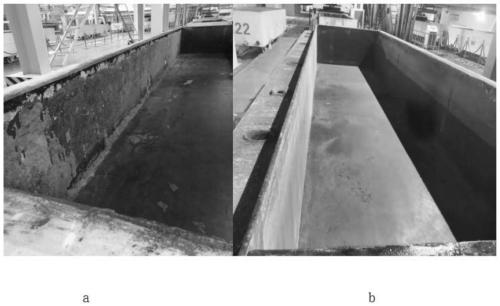

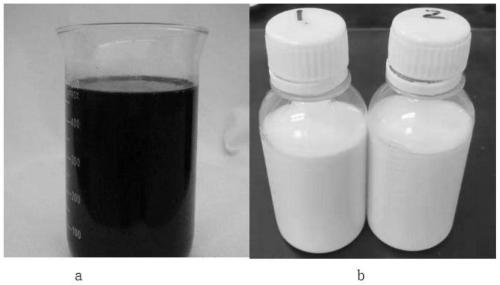

Image

Examples

Embodiment 1

[0027] An aerated brick release agent, which consists of the following components in mass percentage: 35% of 150N type environmental protection base oil, lauryl alcohol polyoxyethylene (9) ether and sorbitan mono Composite emulsifier composed of oleic acid ester 2%, hydroxyethyl cellulose 1.5%, ethyl p-hydroxybenzoate 1.5%, and the balance is water.

[0028] The preparation method is:

[0029] Step 1. Under normal temperature and pressure, mechanically stir the 150N environmentally friendly base oil and the compound emulsifier at a speed of 1000r / min for 10 minutes, then add water and continue stirring at a speed of 1000r / min for 50 minutes. form an emulsion;

[0030] Step 2, when the emulsion turns milky white, add 1.5% hydroxyethyl cellulose and 1.5% ethyl p-hydroxybenzoate and continue to stir at a speed of 1000r / min for 1 hour to form a stable emulsion and discharge it. After testing, demould The viscosity of the emulsion at 25°C is 430mPa·S.

[0031] Centrifuge the air...

Embodiment 2

[0035] A release agent for air-entrained bricks, consisting of the following components by mass percentage: 45% of 250N type environmental protection base oil, glycerol monostearate and polyoxyethylene (20) sorrel with a mass ratio of 1:2 The compound emulsifier composed of alcohol monooleate is 3%, acrylate polymer 1%, oleate 2%, and the rest is water.

[0036] The preparation method is:

[0037] Step 1. Under normal temperature and pressure, first mechanically stir the 250N type environmental protection base oil and the compound emulsifier at a speed of 300r / min for 15 minutes, then add water and continue stirring at a speed of 300r / min for 45 minutes. form an emulsion;

[0038] Step 2, when the emulsion becomes milky white, add 1% of acrylate polymer and 2% of oleic acid ester to continue stirring, the rotation speed is 300r / min, and the time is 1.5h, forming a stable emulsion and discharging. After measurement, the release agent emulsion is 25 The viscosity at °C is 510m...

Embodiment 3

[0042]An air-entraining brick release agent, consisting of the following components in mass percentage: 50% of 500N type environmental protection base oil, polyoxyethylene laurate (9) ester and dodecylamine polyoxygen in a mass ratio of 1:1:1 Compound emulsifier composed of vinyl (10) ether and alkanolamide 6501 is 1.5%, water-soluble starch is 1.5%, dodecenylsuccinic acid is 2%, and the balance is water.

[0043] The preparation method is:

[0044] Step 1. Under normal temperature and pressure, mechanically stir the 500N type environmentally friendly base oil and the compound emulsifier at a speed of 700r / min for 20 minutes, then add water and continue stirring at a speed of 700r / min for 50 minutes. form an emulsion;

[0045] Step 2, when the emulsion becomes milky white, add 1.5% of water-soluble starch and 2% of dodecenylsuccinic acid and continue to stir at a speed of 700r / min for 2 hours to form a stable emulsion and discharge it. After testing, the release agent The vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com