Low-foam flushing fluid and application thereof

A flushing liquid and emulsifier technology, applied in detergent compositions, detergent compounding agents, surface active detergent compositions, etc., can solve the problems of carrying pollution interference test results, unsatisfactory application effect, blockage of flow path system, etc. , to achieve the effect of facilitating industrial production, low cost and improving defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

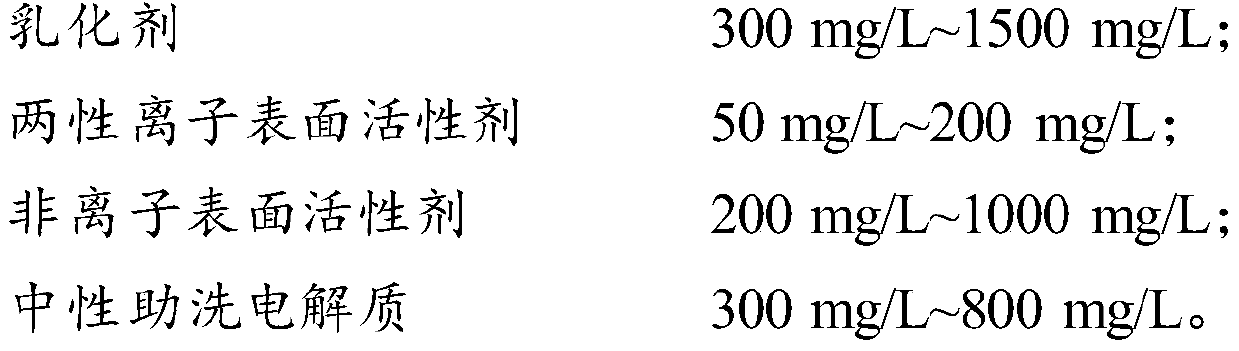

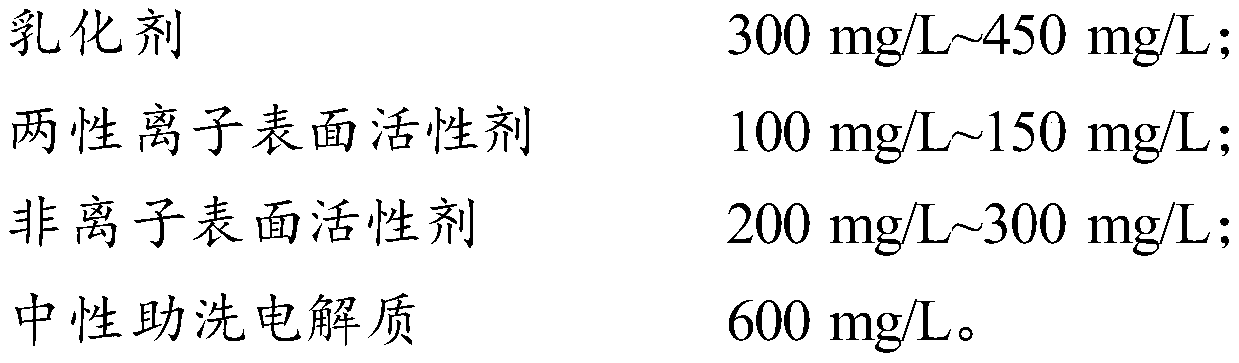

Method used

Image

Examples

Embodiment 1

[0036] Mix sulfonated emulsifier S-15, AMA LF70, isomerized tridecanol polyoxyethylene ether E1310, sodium chloride and water, stir at room temperature until the solution becomes clear, and prepare a flushing solution. Each 1L of the flushing solution contains: sulfonate Emulsifier S-15 450mg, AMALF70 100mg, E1310 300mg, sodium chloride 600mg.

Embodiment 2

[0038] Mix Amulan DF22, AMA LF40, isotridecyl alcohol polyoxyethylene ether E1308, potassium chloride and water, stir at room temperature until the solution becomes clear, and prepare a flushing solution. Each 1L of the flushing solution contains: Amulan DF22 300mg, AMA LF40 150mg , E1308 200mg, potassium chloride 600mg.

Embodiment 3

[0055] Embodiment 3 and the comparison of listed product physicochemical index

[0056] (1) Use pH meter, digital conductivity meter and Roche foam meter respectively to the original imported rinsing solution, domestic rinsing solution, comparative examples 1 to 8, and Example 1 of the present invention and Example 2. After 1 month, 4 months, and 6 months, the appearance, pH value, electrical conductivity and foam performance of the flushing solution were measured, and the results are shown in Table 1.

[0057] Table 1 Physicochemical indicators of flushing fluid

[0058]

[0059] The implementation results in Table 1 show that the physical and chemical properties of the flushing liquid provided by the present invention are similar to those of the original imported flushing liquid, while the foaming property is significantly lower than that of the commercially available flushing liquid, and the stability is good.

[0060] (2) Under the same working conditions, the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com