Penetrating type sweat guide and quick-drying composite fabric and preparation method thereof

A composite fabric and penetrating technology, which is applied in the field of textile and clothing, can solve the problems of not absorbing sweat, and achieve the effects of soft hand feeling, comfortable wearing and prolonged drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

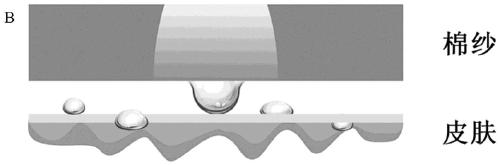

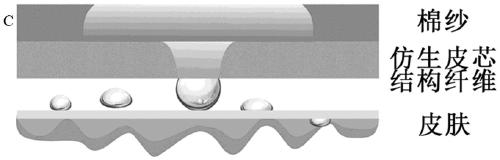

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a bionic skin-core structure fiber, comprising the following steps:

[0053] (1) polyamide is blended with polyamide hydrophilic masterbatch accounting for 2.0wt% of polyamide and 2.5wt% antibacterial masterbatch (TFA11) chips to obtain a cortical mixture;

[0054] (2) polyester is blended with polyester 2.5wt% color masterbatch (EFB06, blue) and 2.5wt% soft masterbatch chips to obtain a core layer mixture;

[0055] (3) Melting and spinning the resulting skin layer mixture and core layer mixture (mass ratio: 55:45) using a spinning coating device (CN209368400 U) to obtain semi-finished products of bionic skin-core structure fibers;

[0056] (4) The obtained bionic skin-core structural fiber semi-finished product was sequentially subjected to 70°C hot water stretching, 125°C steam stretching, crimping, and 80°C heat setting to obtain the bionic skin-core structural fiber.

[0057] A method for preparing a penetrating sweat-conducting and quick-dr...

Embodiment 2

[0062] A preparation method of a bionic skin-core structure fiber, comprising the following steps:

[0063] (1) polyamide is blended with polyamide hydrophilic masterbatch accounting for 5.0wt% of polyamide and 2.5wt% antibacterial masterbatch (TFA12) chips to obtain a cortical mixture;

[0064] (2) polyester is blended with polyester 2.5wt% color masterbatch (EFB06, blue) and 2.5wt% soft masterbatch chips to obtain a core layer mixture;

[0065] (3) Melting and spinning the obtained skin layer mixture and core layer mixture (mass ratio is 45:55) using a spinning coating device (CN209368400 U) to obtain semi-finished products of bionic skin-core structure fibers;

[0066] (4) The obtained bionic skin-core structural fiber semi-finished product is sequentially subjected to 90°C hot water stretching, 130°C steam stretching, crimping, and 90°C heat setting to obtain the bionic skin-core structural fiber.

[0067] Example 2 The preparation method of the penetrating sweat-conducti...

Embodiment 3

[0069] A preparation method of a bionic skin-core structure fiber, comprising the following steps:

[0070] (1) blending polyethylene with 10.0wt% polyethylene hydrophilic masterbatch and 2.5wt% antibacterial masterbatch (TFA13) chips to obtain a skin layer mixture;

[0071] (2) polyester is blended with polyester 2.5wt% color masterbatch (EFB06, blue) and 2.5wt% soft masterbatch chips to obtain a core layer mixture;

[0072] (3) Melt and spin the obtained skin layer mixture and core layer mixture (mass ratio is 50:50) using a spinning coating device (CN209368400 U) to obtain a semi-finished product of bionic skin-core structure fiber;

[0073] (4) The obtained bionic skin-core structural fiber semi-finished product is sequentially subjected to 80°C hot water stretching, 120°C steam stretching, crimping, and 80°C heat setting to obtain the bionic skin-core structural fiber.

[0074] Example 3 The preparation method of the penetrating sweat-conducting and quick-drying composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com