A kind of antibacterial anti-wrinkle fabric with flame retardant properties and its preparation process

An anti-wrinkle fabric and flame retardant technology, applied in the field of clothing fabrics, can solve the problems of reduced flame retardant performance of clothing, low antibacterial performance of fabrics, low flame retardant performance, etc., and achieve improved antibacterial performance, uniform antibacterial performance, and high antibacterial performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

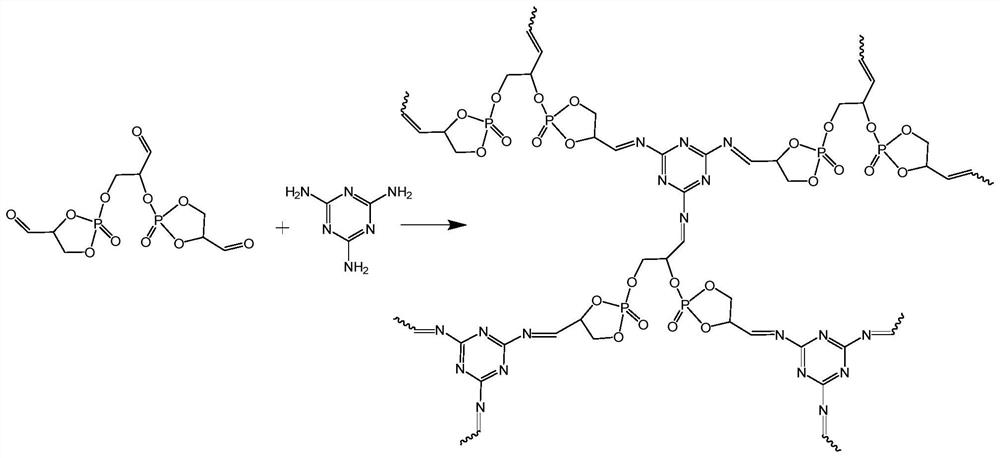

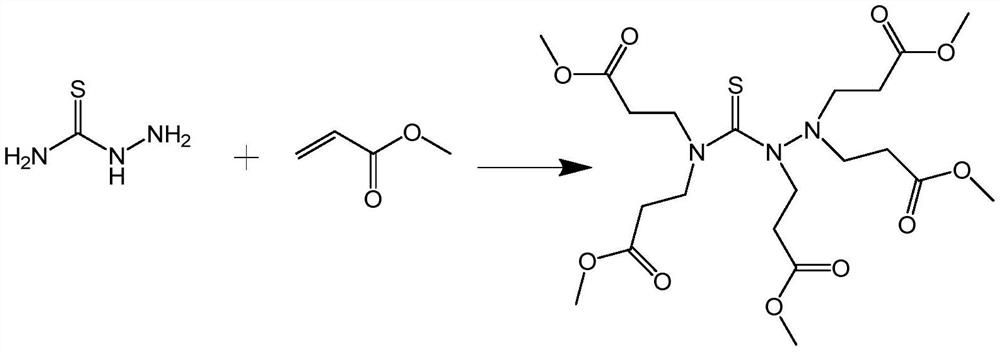

[0031] The concrete preparation process of polyamino modifier is as follows:

[0032] Step 1: Take by weighing 0.91g thiosemicarbazide and add in 6mL ethanol solution and stir to dissolve, then add the dissolved thiosemicarbazide solution in an ice-water bath, then add 3.4g methyl acrylate dropwise to the reaction vessel, and control the rate of addition as 3ml / min, after the dropwise addition is complete, stir and react for 50min, then raise the temperature to normal temperature and stir for 2h, then carry out vacuum distillation to obtain product A, the reaction structure is as follows;

[0033]

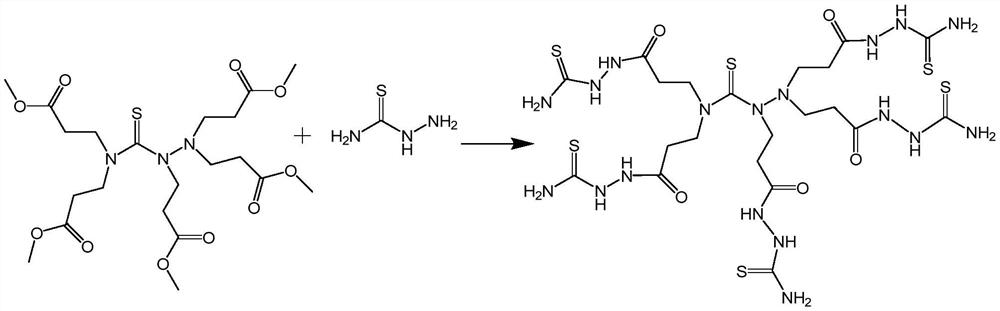

[0034] Step 2: Add 10g of the product A prepared in step 1 and 90mL of ethanol to the reactor, and at the same time, add thiosemicarbazide to ethanol and stir to dissolve it into a thiosemicarbazide solution with a mass concentration of 60%, and then add it dropwise to the reactor 15g of the configured thiosemicarbazide solution, the rate of addition was controlled to be 3ml / min...

Embodiment 2

[0037] The concrete preparation process of polyamino modifier is as follows:

[0038] Step 1: Take by weighing 0.91g thiosemicarbazide and add in 6mL ethanol solution and stir to dissolve, then add the dissolved thiosemicarbazide solution in an ice-water bath, then add 4.3g methyl acrylate dropwise to the reaction vessel, and control the rate of addition as 3ml / min, after the dropwise addition is complete, stir and react for 50min, then raise the temperature to normal temperature and stir for 2h, then carry out vacuum distillation to obtain product A, the reaction structure is as follows;

[0039]

[0040] Step 2: Add 10g of the product A prepared in step 1 and 90mL of ethanol to the reactor, and at the same time, add thiosemicarbazide to ethanol and stir to dissolve it into a thiosemicarbazide solution with a mass concentration of 60%, and then add it dropwise to the reactor 17.5g of thiosemicarbazide solution was prepared, and the rate of addition was controlled to be 3ml...

Embodiment 3

[0043] The concrete preparation process of polyamino modifier is as follows:

[0044] Step 1: Take by weighing 0.91g thiosemicarbazide and add in 6mL ethanol solution and stir to dissolve, then add the dissolved thiosemicarbazide solution into an ice-water bath, then add 1.72g methyl acrylate dropwise to the reaction vessel, and control the rate of addition as 3ml / min, after the dropwise addition is complete, stir and react for 50min, then raise the temperature to normal temperature and stir for 2h, then carry out vacuum distillation to obtain product A, the reaction structure is as follows;

[0045]

[0046] Step 2: Add 10g of the product A prepared in step 1 and 90mL of ethanol to the reactor, and at the same time, add thiosemicarbazide to ethanol and stir to dissolve it into a thiosemicarbazide solution with a mass concentration of 60%, and then add it dropwise to the reactor 15g of the configured thiosemicarbazide solution, the rate of addition was controlled to be 3ml / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com