External wall tiling machine

A tile tiling machine and exterior wall technology, which is applied in the direction of construction and building construction, can solve the problems of tiles being not firmly paved, hollow tiles and walls, and easy to fall, so as to improve the efficiency of paving and prevent voids Drum drop, the effect of ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

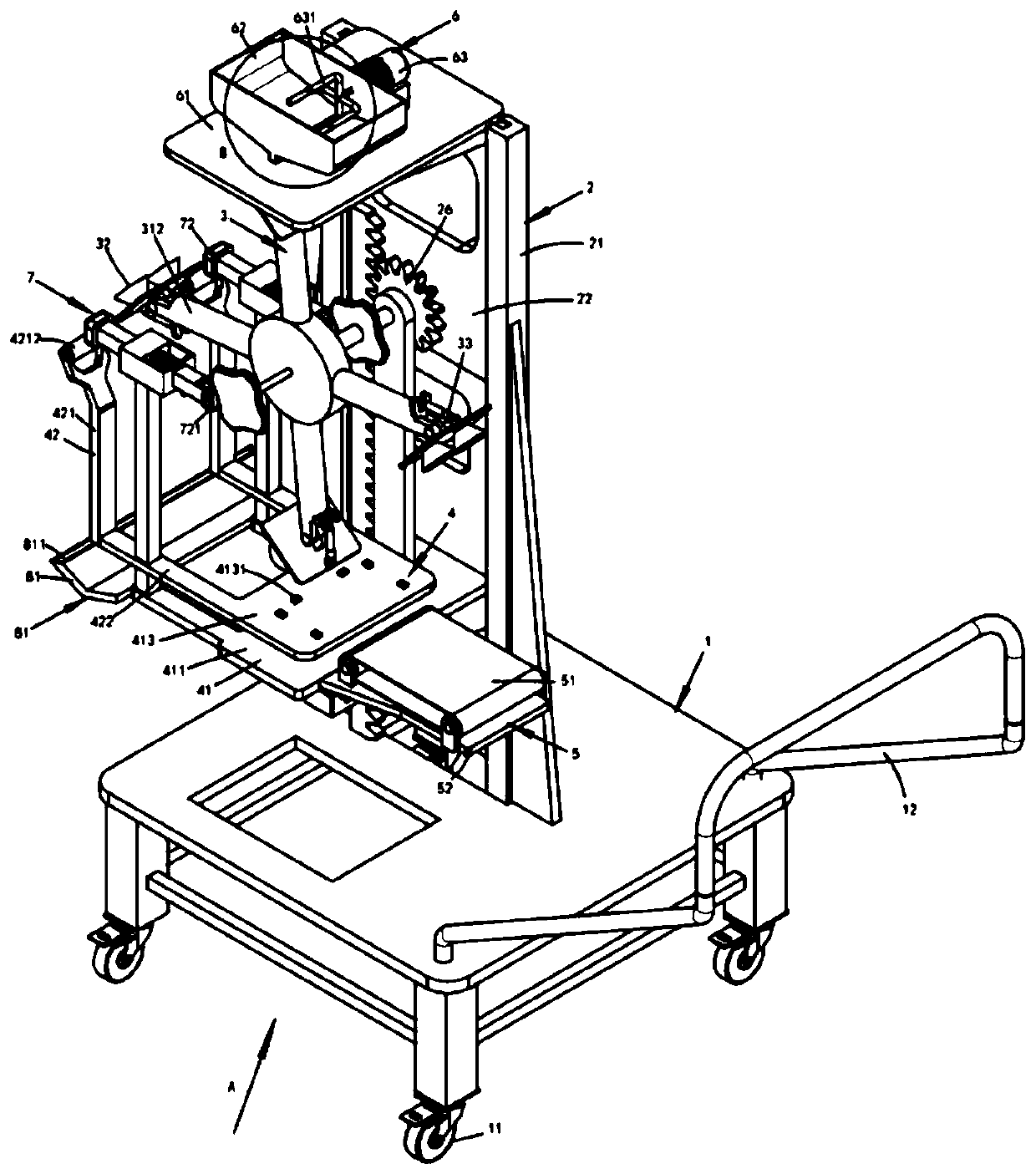

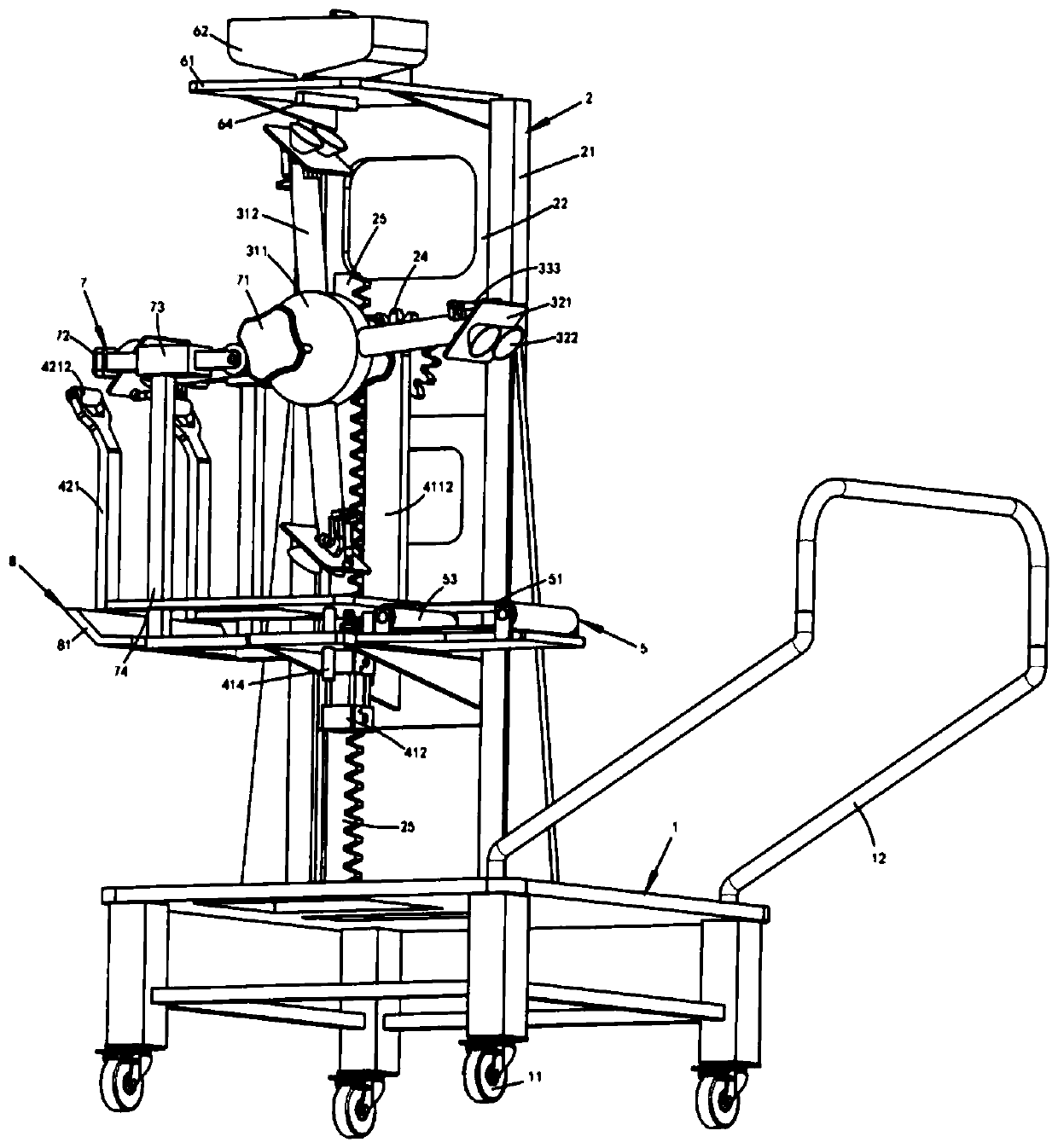

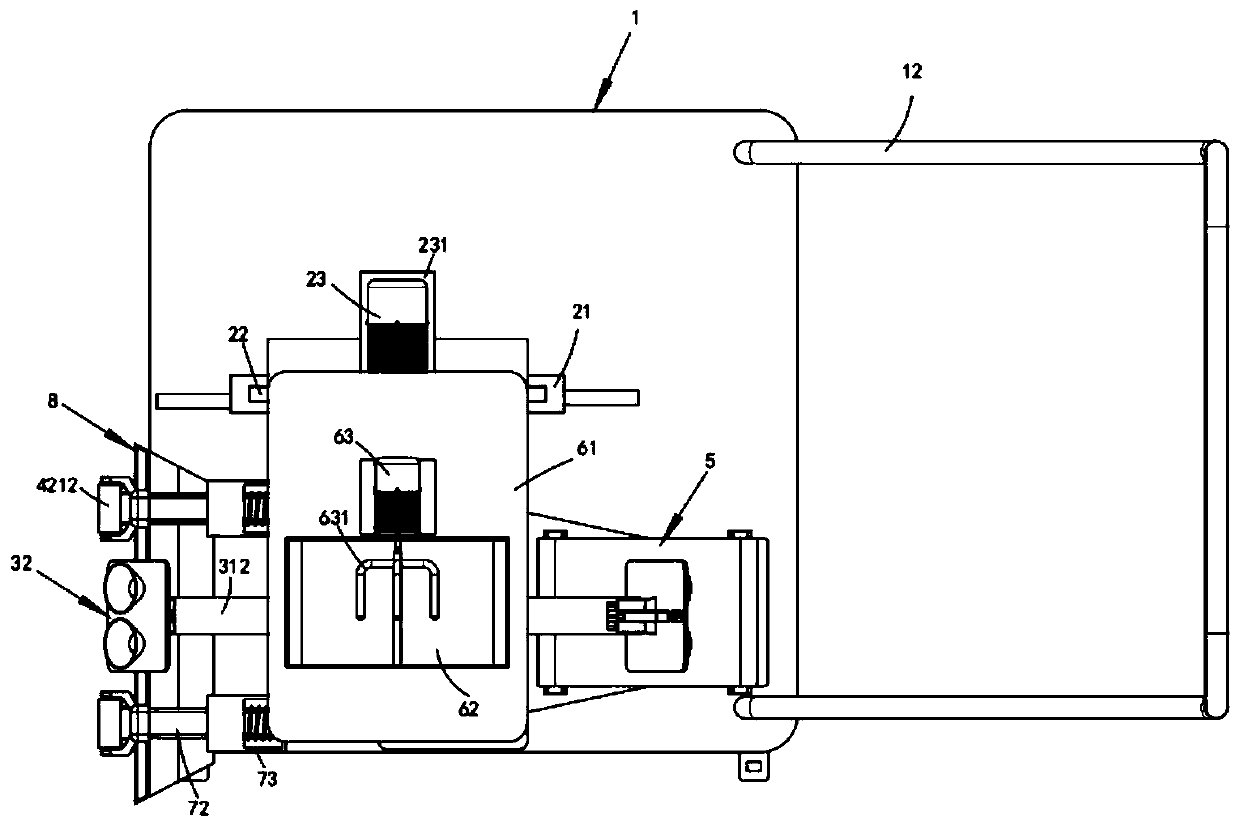

[0047] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of exterior wall tiling machine, comprises workbench 1, is characterized in that, also comprises:

[0048] Lifting mechanism 2, described lifting mechanism 2 comprises guide rail 21 fixedly installed on described workbench 1, guide plate 22 and power unit 26, a pair of described guide rails 21 are fixed on described workbench 1, described The guide plate 22 is slidably arranged between the guide rails 21, and the power unit 26 is installed on the guide plate 22 and drives the guide plate 22 to slide up and down;

[0049] Material transport mechanism 3, this material transport mechanism 3 comprises rotating unit 31, adsorption unit 32 and control unit 33, and described rotating unit 31 comprises the rotating disk 311 that is coaxial with the rotating shaft of described power unit 26 and is fixedly connected and spoke shape is arranged on The connecting rod 312 on the turntable 311, the adsorpt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap