Residual service life prediction method for large-scale equipment based on multi-parameter feature fusion

A large-scale equipment and feature fusion technology, applied in the direction of specific mathematical models, calculation models, design optimization/simulation, etc., can solve problems such as single parameters, and achieve good prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

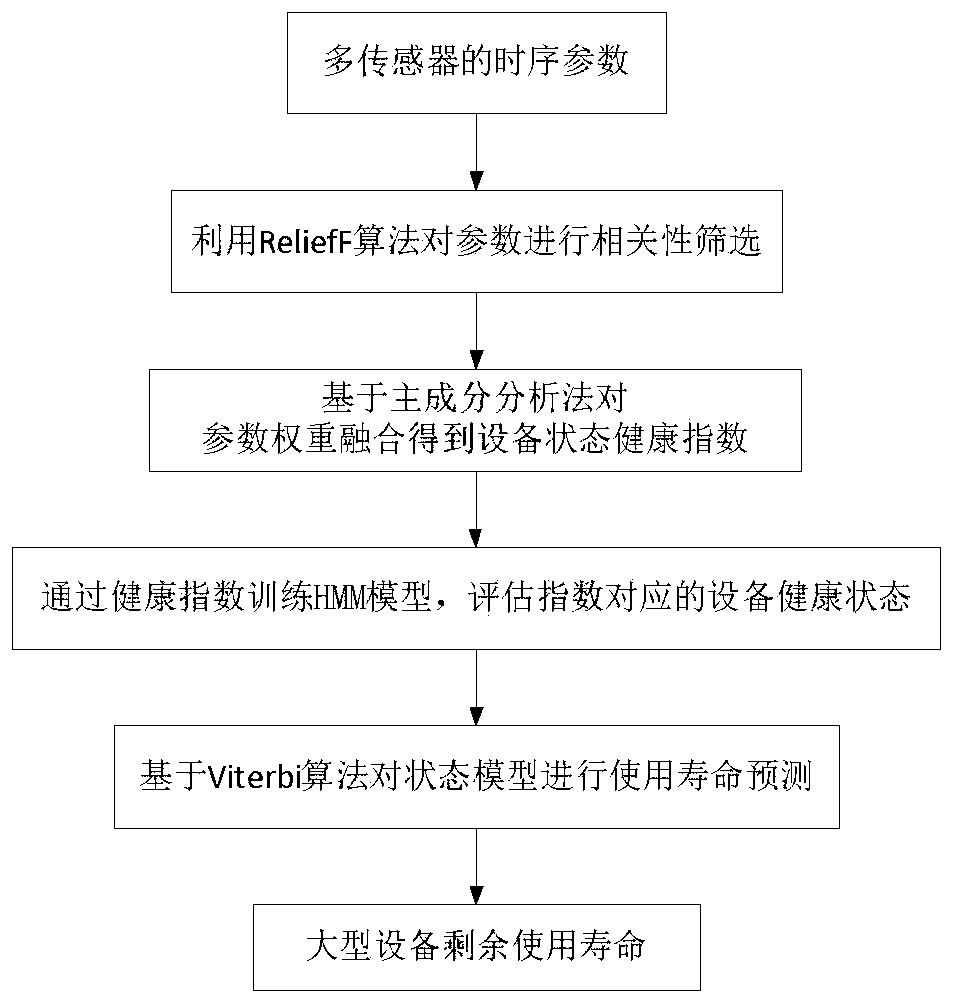

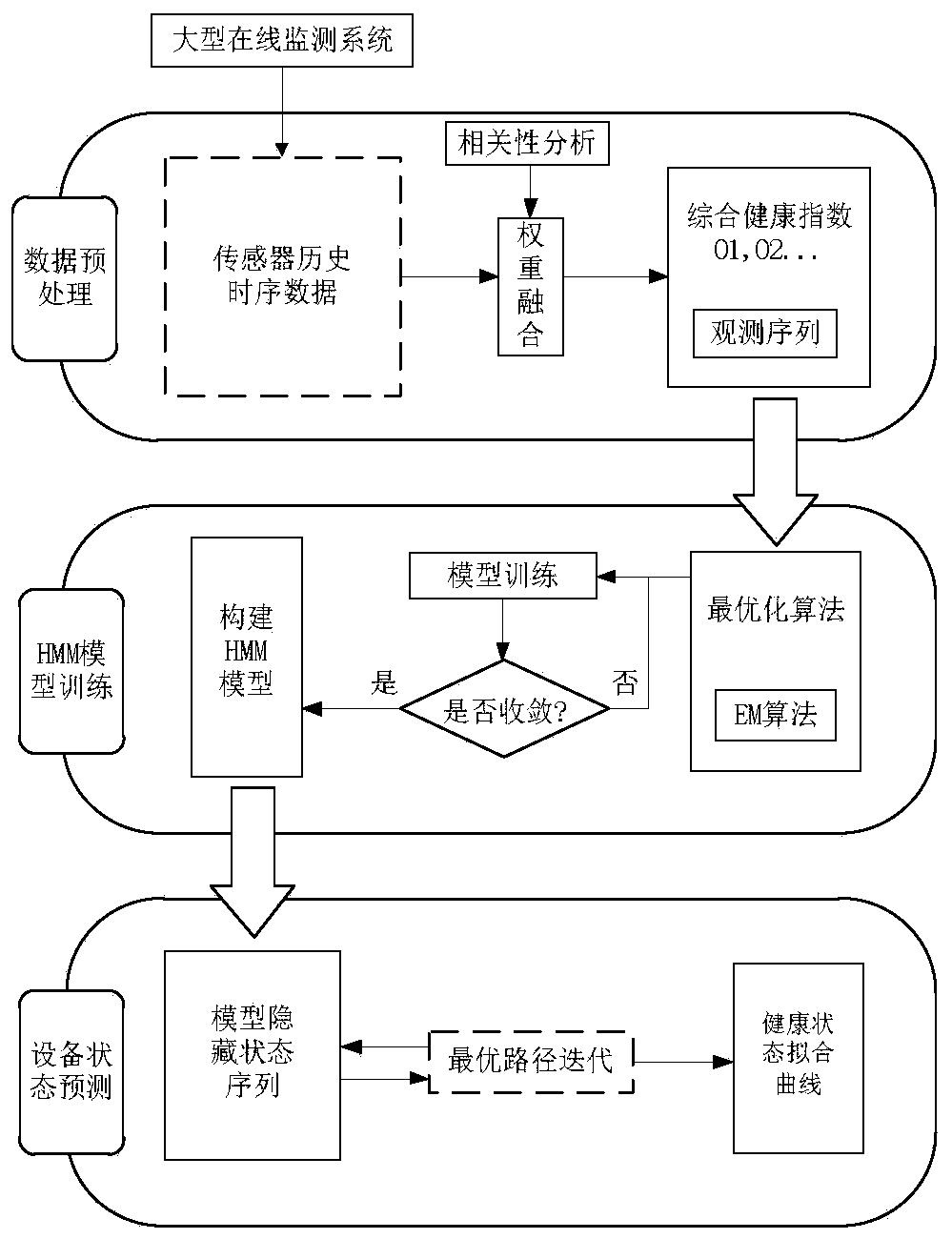

[0017] Please refer to figure 1 As shown, the method for predicting the remaining service life of large equipment based on multi-parameter feature fusion in the present invention mainly includes two parts: data processing and state prediction. The data processing part includes: parameter screening, which is used to remove parameters with similar influencing factors in equipment use, so that the parameter types are diversified; feature extraction, which is used to analyze the linear changes of time series data of different types of parameters, and use matrix decomposition to find their corresponding feature items; weight fusion, which is used to fuse various performance parameters into a comprehensive health index, which is convenient for subsequent model data substitution. The state prediction part includes: model establishment, on the basis of multi-parameter feature fusion, using machine learning algorithms to construct a state model for equipment based on historical perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com