Label and manufacturing process thereof

A production process and labeling technology, which is applied in the field of label and its production process, can solve the problems of self-adhesive label adhesion reduction, self-adhesive label falling off, etc., and achieve the effect of saving resources, increasing service life, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

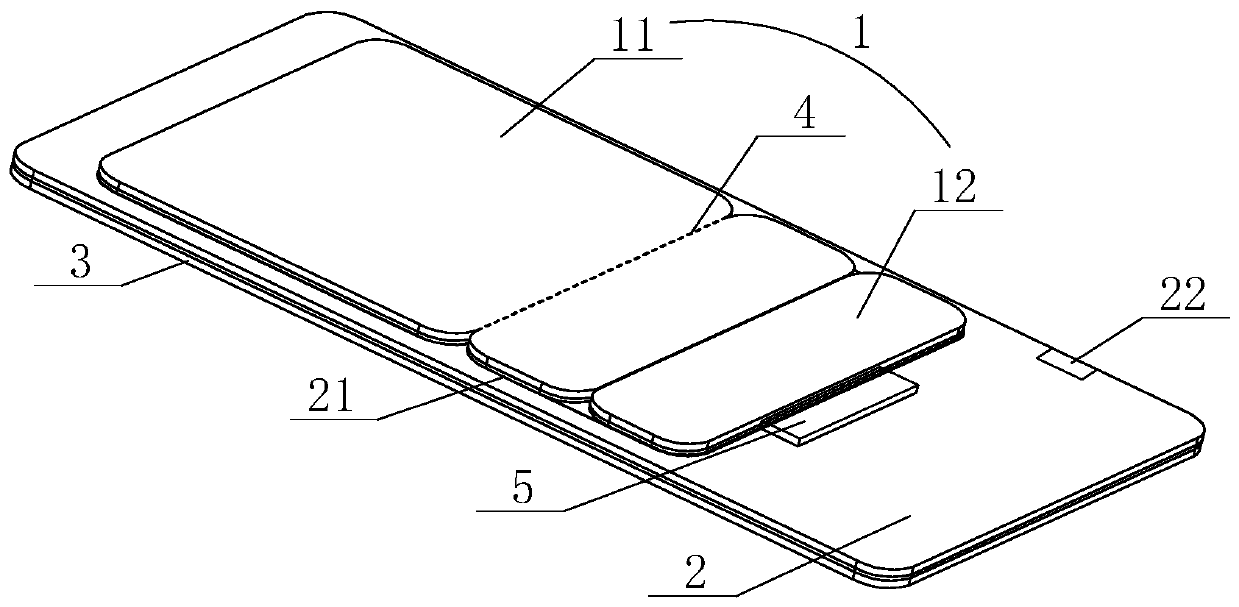

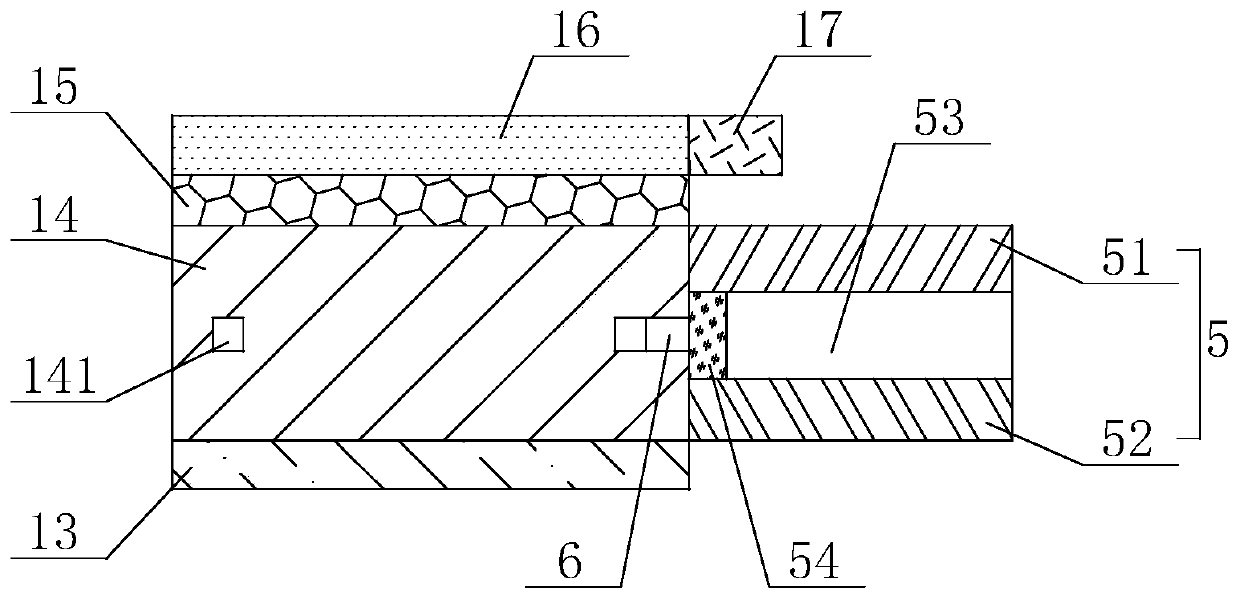

[0047] refer to figure 1 , is a kind of label disclosed by the present invention, which includes a label part 1, a release paper layer 2 and a light film 3 pasted in sequence. The label part 1 includes a first label part 11 and a multi- There are two second marking parts 12, and the first ant line 4 is arranged between the first marking part 11 and one of the second marking parts 12. The label part 1 also includes a self-adhesive layer 13 , a base layer 14 and a label layer 15 , the base layer 14 is pasted on one side of the self-adhesive layer 13 , and the label layer 15 is fixed on the side of the base layer 14 away from the self-adhesive layer 13 .

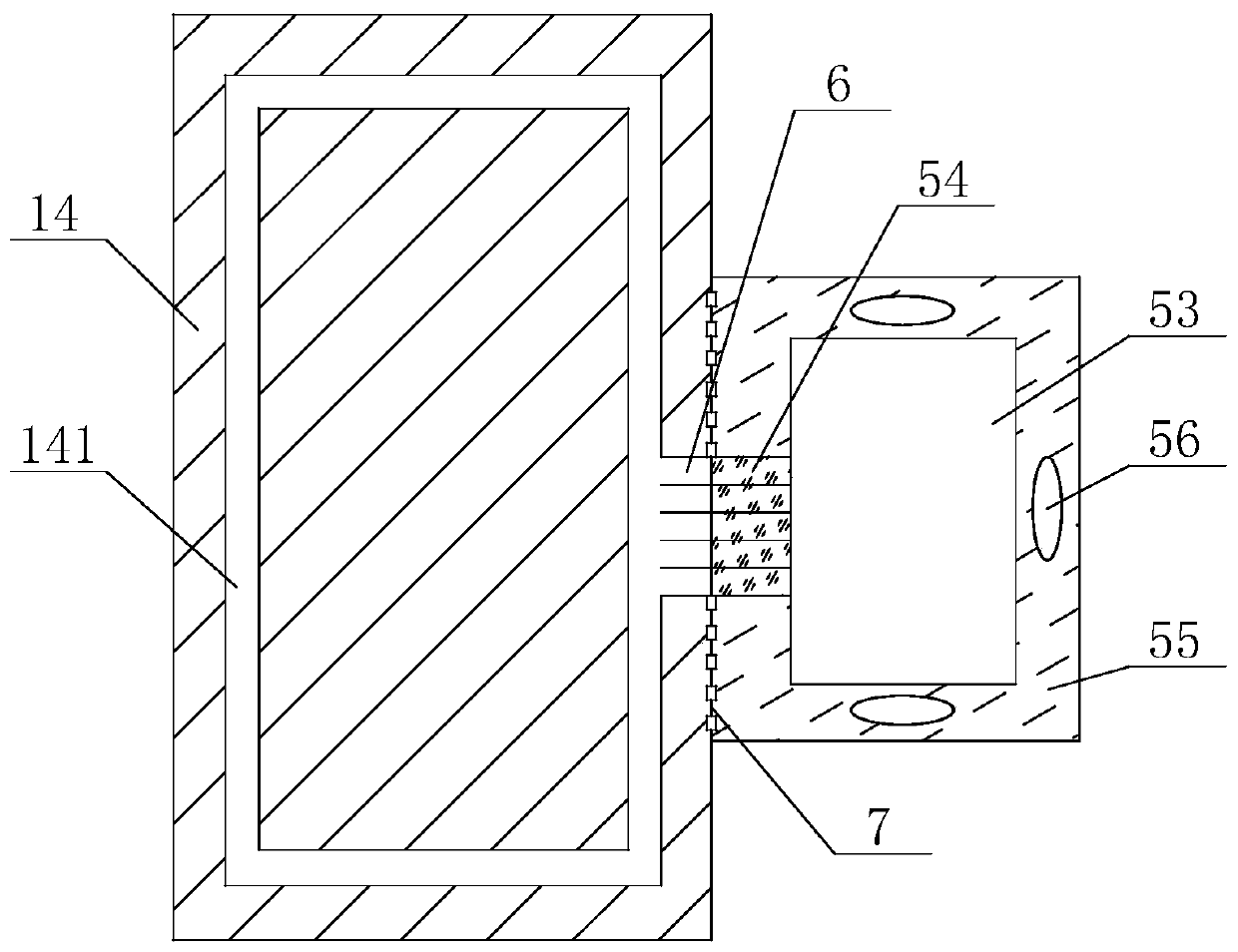

[0048] Wherein, a reinforcing part 5 is provided on one side of the marking part 1 , and an adhesive and a fluorescent agent that can enter the base layer 14 are provided inside the reinforcing part 5 . In this embodiment, the adhesive preferably adopts oily glue, which is formed by dissolving acrylic acid or polyurethane with...

Embodiment 2

[0059] A label making process, with reference to Figure 4 , including the following steps:

[0060] Step S1: label printing, using imported dumb silver PET self-adhesive material with reinforcement 5, and printing with silicone oil and cursor printing on the side of the material provided with release paper layer 2 by a printing machine;

[0061] Step S2: die-cutting the reverse side of the label, die-cutting the printed label by a die-cutting machine, forming a plurality of die-cutting impressions 21 on the die-cutting release paper layer 2, and the separation formed between the die-cutting impressions 21 The area of the type paper layer 2 is the same as the area of the first marking part 11;

[0062] Step S3: Composite the optical film 3, trace the cursor on the side of the label with the release paper layer 2, and perform the optical film 3 compounding through the trademark printing machine. It is necessary to ensure that the optical film 3 is laminated straight so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com