Rice seedling raising medium and production method thereof

A technology for raising seedlings and rice, applied in the directions of planting substrates, botanical equipment and methods, culture medium, etc., can solve the problems of ineffective utilization of rice straw resources, huge discharge of cow dung, and ecological environment pollution. The effect of running off with water, promoting plant growth and reducing the height of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

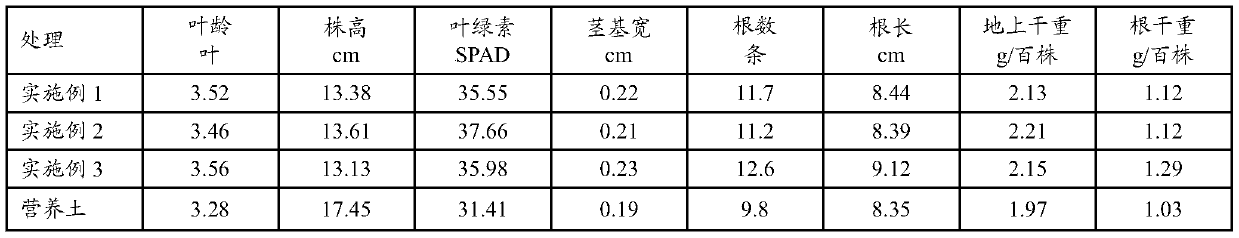

Examples

Embodiment 1

[0042] Decomposed cow dung is mixed with 80% of fresh cow dung and 20% of rice straw according to the volume percentage, and 2kg of microbial compound bacterial agent is added to every 1000kg of fresh cow dung, and it is obtained through 2 times of fermentation and decompression.

[0043]Weigh 4.5g of paclobutrazol, mix it with 9kg of zeolite, add 3.5kg of ammonium sulfate, 2.5kg of superphosphate, 7kg of ferrous sulfate heptahydrate, and 1kg of zinc sulfate, and pour it into a stirring pot for 10 minutes. Take 1L of wood vinegar stock solution and dilute it 40 times, spray it with a sprayer while stirring in a stirring pot, stir for more than 20 minutes and mix thoroughly to prepare 1 part of the preparation.

[0044] Crush and sieve the decomposed cow dung to remove impurities, 1m 3 Add 40kg of zeolite and 1 part of preparation agent to the cooked rotten cow dung, and mix well.

Embodiment 2

[0046] The decomposed cow dung is mixed with 75% of fresh cow dung and 25% of rice straw in volume percentage, and 2kg of microbial compound bacterial agent is added to every 1000kg of fresh cow dung, and it is obtained through 2 times of fermentation and decomposition.

[0047] Weigh 4.5g of paclobutrazol, mix it with 9kg of zeolite, add 3.5kg of ammonium sulfate, 2.5kg of superphosphate, 7kg of ferrous sulfate heptahydrate, and 1kg of zinc sulfate, and pour it into a stirring pot for 10 minutes. Take 1L of wood vinegar stock solution and dilute it 40 times, spray it with a sprayer while stirring in a stirring pot, stir for more than 20 minutes and mix thoroughly to prepare 1 part of the preparation.

[0048] Crush and sieve the decomposed cow dung to remove impurities, 1m 3 Add 40kg of zeolite and 1 part of compounding agent to the decomposed cow dung, and mix well.

Embodiment 3

[0050] The decomposed cow dung is mixed with 70% of fresh cow dung and 30% of rice straw according to the volume percentage, and 2kg of microbial compound bacterial agent is added to every 1000kg of fresh cow dung, and it is obtained through 2 times of fermentation and decompression.

[0051] Weigh 4.5g of paclobutrazol, mix it with 9kg of zeolite, add 3.5kg of ammonium sulfate, 2.5kg of superphosphate, 7kg of ferrous sulfate heptahydrate, and 1kg of zinc sulfate, and pour it into a stirring pot for 10 minutes. Take 1L of wood vinegar stock solution and dilute it 40 times, spray it with a sprayer while stirring in a stirring pot, stir for more than 20 minutes and mix thoroughly to prepare 1 part of the preparation.

[0052] Crush and sieve the decomposed cow dung to remove impurities, 1m 3 Add 40kg of zeolite and 1 part of preparation agent to the cooked rotten cow dung, and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com