Green mixed type feed additive as well as preparation method and main component detection method thereof

A feed additive and mixed technology, applied in the field of green mixed feed additives and its preparation, can solve the problems of weak animal resistance, affecting growth and development, and prone to diseases, so as to promote growth, reduce heat stress response, and ensure The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

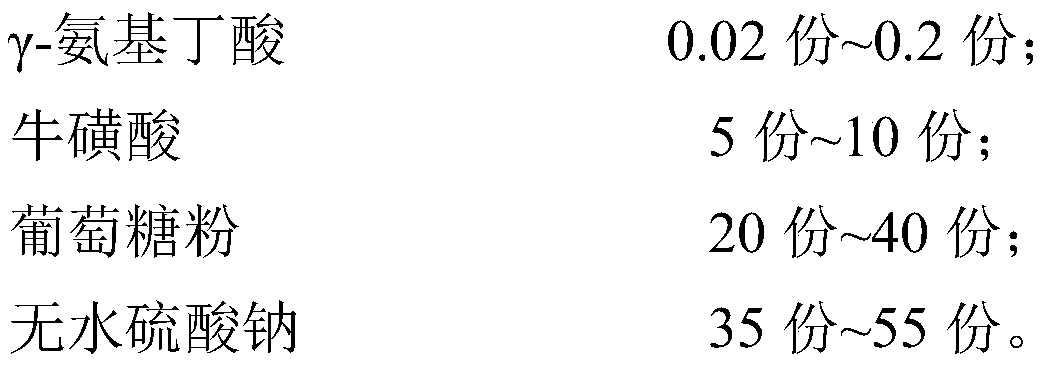

[0048] A method for preparing a green mixed feed additive, comprising:

[0049] Step S1, uniformly mixing the full amount of γ-aminobutyric acid, the full amount of taurine and the first portion of glucose powder to prepare the first mixture;

[0050] Step S2, uniformly mixing the first mixture prepared in step S1 with the second portion of glucose powder to prepare a second mixture;

[0051] Step S3, uniformly mixing the second mixture prepared in step S2 with the remaining amount of glucose powder and the whole amount of anhydrous sodium sulfate to prepare a color-mixed feed additive.

[0052] Further, the first portion of glucose powder accounts for 20%-30% of the weight of the whole amount of glucose powder; the second portion of glucose powder accounts for 40%-60% of the weight of the entire amount of glucose powder.

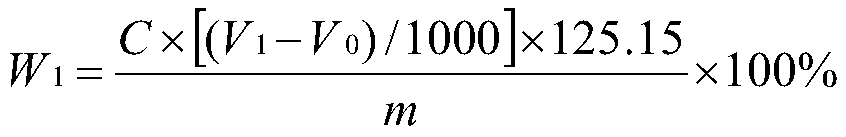

[0053] A method for detecting the main component of a green mixed feed additive, wherein the green mixed feed additive is the above-mentioned feed additiv...

Embodiment 1

[0068] The γ-aminobutyric acid prepared by biological fermentation is used, and the feed additive is mixed according to the stepwise dilution method, and the specific method is as follows:

[0069] Gamma-aminobutyric acid 0.02kg, taurine 5kg, glucose powder 10kg mix homogeneously, obtain the first mixture, then add 20kg glucose powder in the first mixture and mix homogeneously, obtain the second mixture, will add glucose in the second mixture Powder 10Kg and anhydrous sodium sulfate 55kg mix homogeneously. Thereby about 100 kg of feed additives were produced.

Embodiment 2

[0071] The γ-aminobutyric acid prepared by biological fermentation is used, and the feed additive is mixed according to the stepwise dilution method, and the specific method is as follows:

[0072] Gamma-aminobutyric acid 0.04kg, taurine 5kg, glucose powder 10kg mix uniformly, obtain the first mixture, then add 20kg glucose powder in the first mixture and mix homogeneously, obtain the second mixture, add to the second mixture Add glucose powder 10Kg and anhydrous sodium sulfate 55kg and mix well. Thereby about 100 kg of feed additives were produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com