Making method of truffle potato chips and truffle potato chips

A production method and potato chip technology, which are applied in the coating of food, food ingredients as coating agents, food ingredients as odor modifiers, etc., can solve the problem of limited shelf life of fresh truffles, shortened production season, poor quality, etc. problems, to achieve the effect of reducing shedding, improving adhesion, and not easily lost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

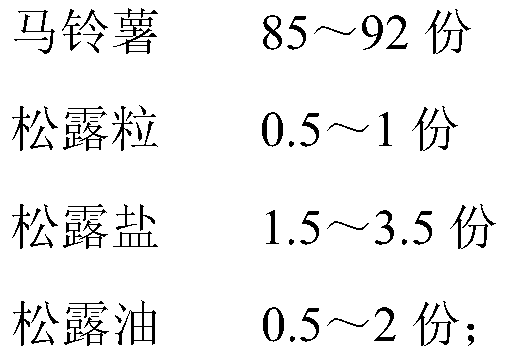

[0052] In this example, the following method is used to make truffle potato chips:

[0053] (1) Carrying out micro-grinding treatment to truffles to obtain truffle grains with a particle size of 200 μm, and simultaneously selecting truffle oil and truffle salt for subsequent use;

[0054] (2) Wash and peel the potatoes and cut them into slices with a thickness of 1.8 mm, and wash the potato slices in cold water for 10 minutes;

[0055] (3) Put the potato slices cleaned in step (2) into boiling water for precooking for 2.5 minutes, take them out and dry them, put them into a fryer and fry them for 32 minutes at a temperature of 176° C. to make potato chips. The frying oil is It is made by mixing palm oil and truffle oil at a mass ratio of 9:1;

[0056] (4) First, add the potato chips fried in step (3) into the seasoning machine and start the operation, then add truffle oil accounting for 0.2wt% of the total weight of potato chips, truffle grains accounting for 0.45wt% of the t...

Embodiment 2

[0060] In this example, the following method is used to make truffle potato chips:

[0061] (1) The truffles are finely pulverized to obtain truffles with a particle size of 350 μm, and truffle oil and truffle salt are selected for subsequent use;

[0062] (2) Wash and peel the potatoes and cut them into slices with a thickness of 1.6 mm, and wash the potato slices in cold water for 5 minutes;

[0063] (3) Put the potato slices cleaned in step (2) into boiling water for precooking for 4 minutes, take them out and dry them, and put them into a fryer to fry them for 30 minutes at a temperature of 180° C. to make potato chips. Palm oil and truffle oil are mixed at a mass ratio of 8:2;

[0064] (4) First, add the potato chips fried in step (3) into the seasoning machine and start the operation, then add truffle oil accounting for 0.6wt% of the total weight of potato chips, truffle grains accounting for 0.9wt% of the total weight of potato chips and Truffle salt accounting for 3....

Embodiment 3

[0068] In this example, the following method is used to make truffle potato chips:

[0069] (1) Carrying out micro-grinding treatment to truffles to obtain truffle grains with a particle size of 200 μm, and simultaneously selecting truffle oil and truffle salt for subsequent use;

[0070] (2) Wash and peel the potatoes and cut them into slices with a thickness of 1.0 mm, and wash the potato slices in cold water for 8 minutes;

[0071] (3) Put the potato slices cleaned in step (2) into boiling water for precooking for 2 minutes, take them out and dry them, and put them into a fryer to fry them for 40 minutes at a temperature of 170° C. to make potato chips. Palm oil and truffle oil are mixed at a mass ratio of 9:1;

[0072] (4) First, add the potato chips fried in step (3) into the seasoning machine and start the operation, then add truffle oil accounting for 1 wt% of the total weight of the potato chips, truffle grains accounting for 1 wt% of the total weight of the potato ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com