Electron beam coaxial wire feeding additive manufacturing equipment and method

A technology of additive manufacturing and coaxial wire feeding, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. It can solve the problems of high processing cost, low precision, and low efficiency, and achieve high melting efficiency and high precision. , Control the effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

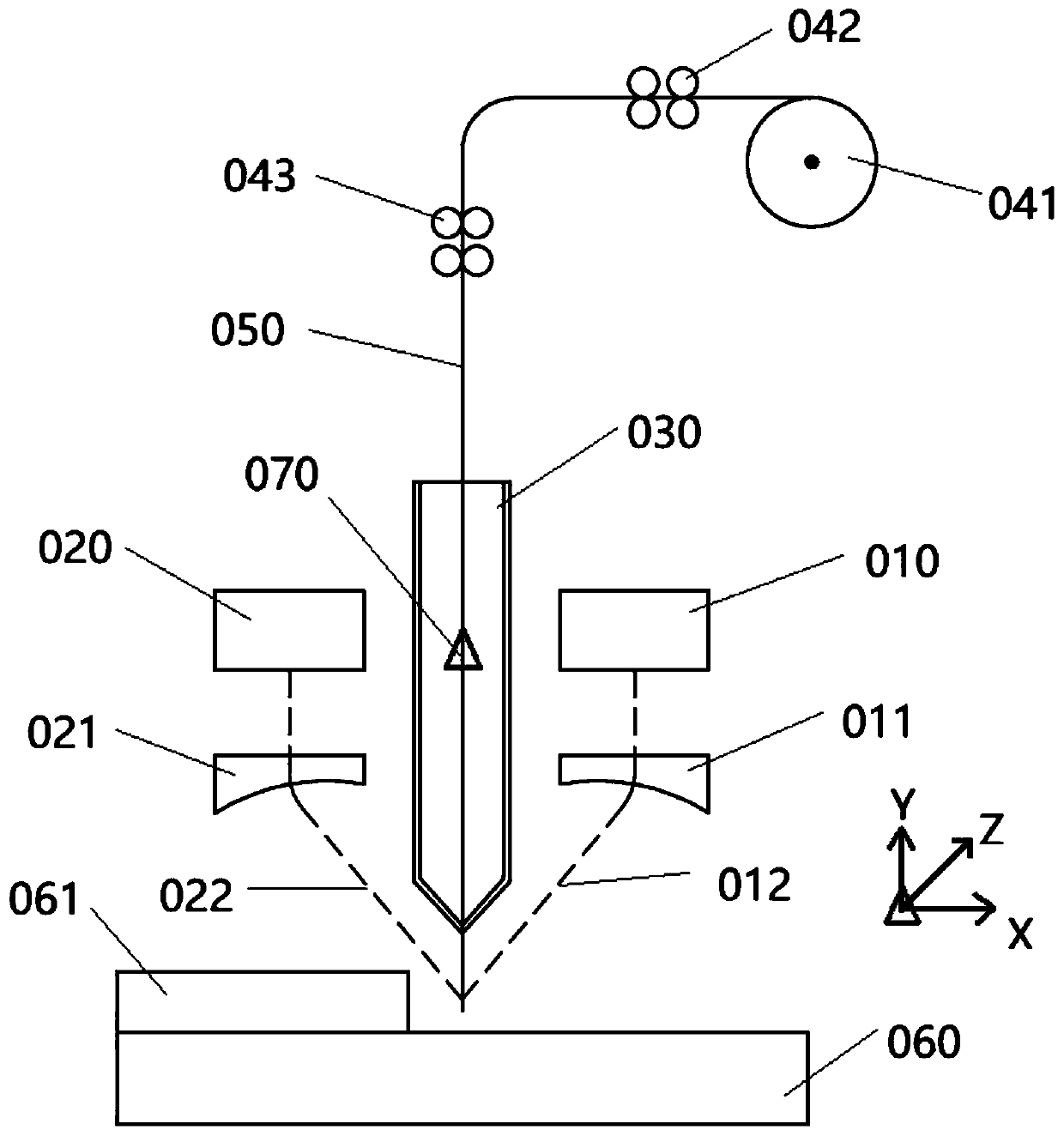

[0028] Such as figure 1 As shown, the electron beam coaxial wire feeding additive manufacturing equipment of the present invention includes a right electron beam gun 010, a right electron beam deflection coil 011, a right electron beam 012, a left electron beam gun 020, a left electron beam deflection coil 021, a left Electron beam 022, wire feeding nozzle 030, wire feeding reel 041, wire feeding guide wheel 042, straightening guide wheel 043, metal wire 050, forming substrate 060, deposition layer 061, electron beam gun XYZ positioning device 070.

[0029] The forming substrate 060 is placed under the wire feeding nozzle 030, and the wire feeding reel 041 with the metal wire 050 wound on it is installed above the wire feeding nozzle 030. The straight guide wheel 043 enters the wire feeding nozzle 030. Wire feeding nozzle 030, the right electron beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com