PU plate and preparation method thereof

A sheet material and preparation process technology, which is applied in the field of PU sheet material and preparation, can solve the problems of product quality degradation, easy cracking, etc., and achieve the effect of improving bonding strength, not easy to crack, and improving surface strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

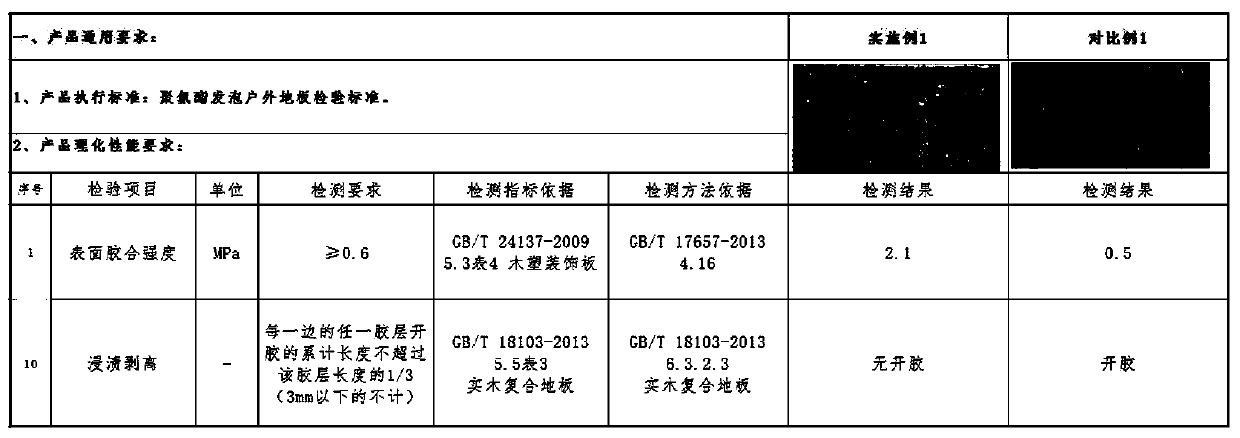

Examples

Embodiment 1

[0038] A kind of PU sheet material, comprises flexible non-foamed PU surface layer and rigid foamed PU core layer, also comprises the PU fusion layer between PU surface layer and PU core layer; Described PU fusion layer comprises the PU surface layer of part and part of the PU core layer, and part of the PU surface layer penetrates into part of the PU core layer, so that the PU surface layer and the PU core layer become a continuous phase. The PU surface layer contains inorganic nanoparticles, the inorganic nanoparticles are ceramic powder, and the addition amount is 20wt% of the mass of the PU surface layer. In this embodiment, the thickness of the PU surface layer is 0.5 cm, the thickness of the PU core layer is 2 cm, and the thickness of the PU fusion layer is about 300 μm.

[0039] A kind of preparation method of PU sheet material, concrete steps are as follows:

[0040] 1. Surface pouring: 1kg toner, 100kg polyether polyol 4110, 50g dibutyltin dilaurate, 20kg isocyanate ...

Embodiment 2

[0045] A kind of PU sheet material, comprises the PU surface layer that does not foam and the PU core layer of foaming, also comprises the PU fusion layer between PU surface layer and PU core layer; Described PU fusion layer comprises the PU surface layer of part and the PU of part The core layer, and part of the PU surface layer penetrates into the part of the PU core layer, so that the PU surface layer and the PU core layer become a continuous phase. The PU surface layer contains inorganic nanoparticles, the inorganic nanoparticles are ceramic powder, and the addition amount is 15wt% of the mass of the PU surface layer. In this embodiment, the thickness of the PU surface layer is 0.5 cm, the thickness of the PU core layer is 2 cm, and the thickness of the PU fusion layer is about 300 μm.

[0046] A kind of preparation method of PU sheet material, concrete steps are as follows:

[0047] 1. Surface pouring: 2kg toner, 100kg polyether polyol YNW-6001A, 80g dibutyltin dilaurate...

Embodiment 3

[0052] A kind of PU sheet material, comprises the PU surface layer that does not foam and the PU core layer of foaming, also comprises the PU fusion layer between PU surface layer and PU core layer; Described PU fusion layer comprises the PU surface layer of part and the PU of part The core layer, and part of the PU surface layer penetrates into the part of the PU core layer, so that the PU surface layer and the PU core layer become a continuous phase. The PU surface layer contains inorganic nanoparticles, the inorganic nanoparticles are ceramic powder, and the addition amount is 15wt% of the mass of the PU surface layer. In this embodiment, the thickness of the PU surface layer is 0.3 cm, the thickness of the PU core layer is 1.8 cm, and the thickness of the PU fusion layer is about 200 μm.

[0053] A kind of preparation method of PU sheet material, concrete steps are as follows:

[0054] 1. Surface pouring: 3kg toner, 100kg polytetrahydrofuran ether glycol, 100g amine catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com