Fast packaging machine and packaging method for smart carbon skateboard products

A technology of board finished products and fast packaging, applied in packaging, transportation, packaging, containers, etc., can solve the problems of not being able to adapt to carbon skateboard packaging at the same time, packaging materials cannot be reused, blockboard strength is not enough, etc., to avoid non-reusable , solve the effect of non-reusable and reduce labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

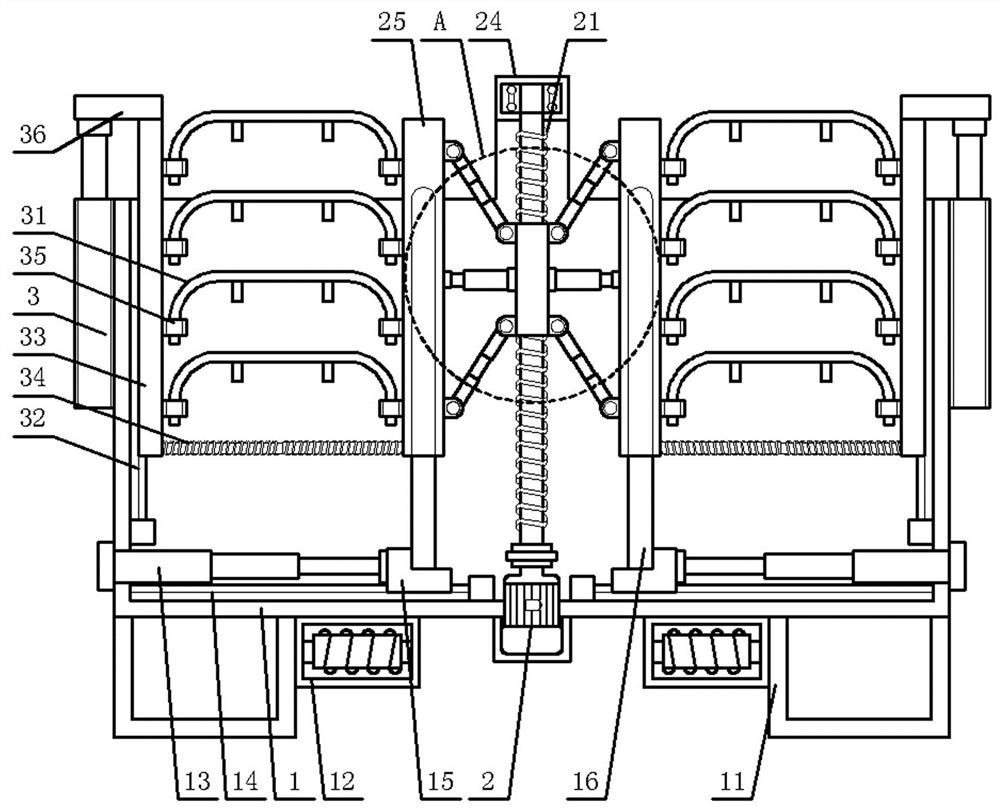

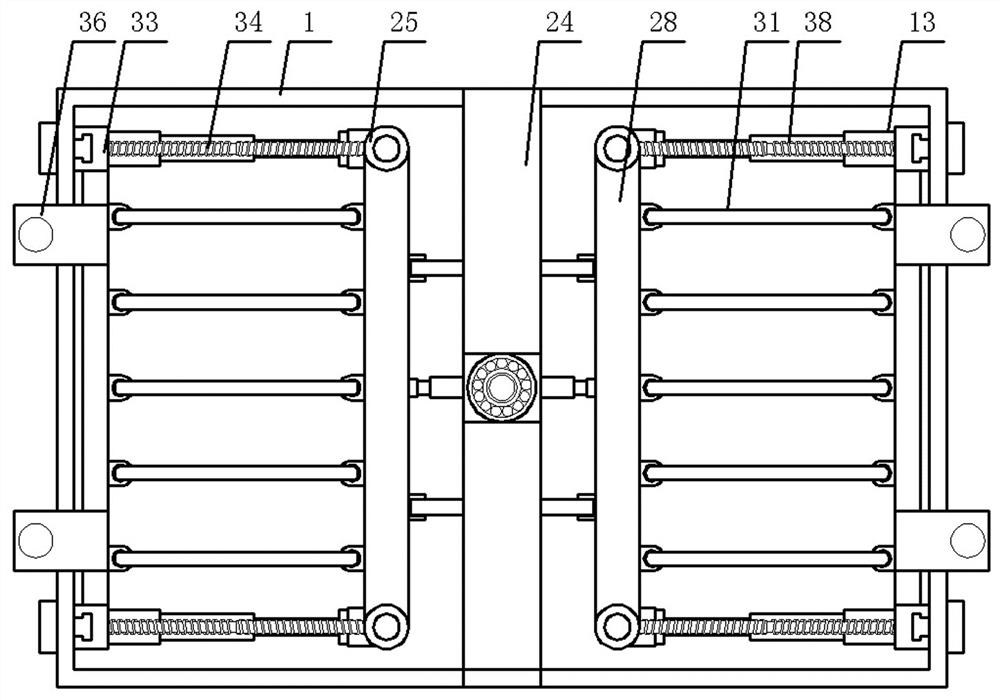

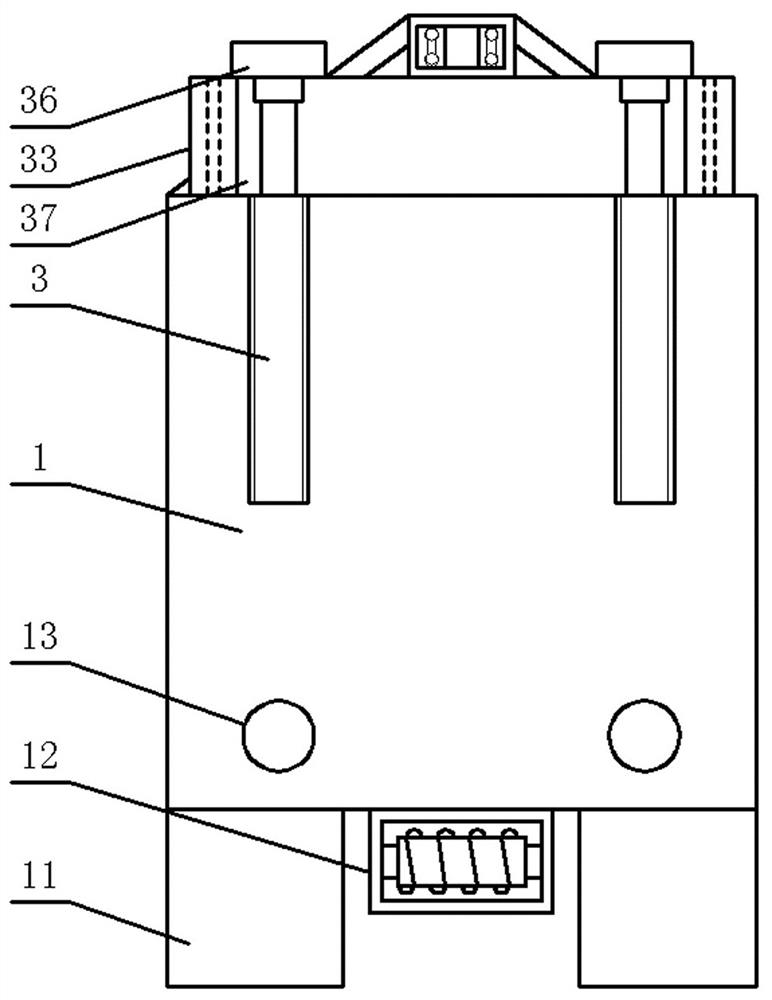

[0029] Embodiment 1: see Figure 1-4 , a fast packaging machine for smart carbon skateboard products, including a bottom box 1, the bottom box 1 is an open rectangular box placed horizontally and horizontally, and the center of the bottom surface of the bottom box 1 is provided with an electric box with an opening facing upwards. A motor 2 with the output end facing up is installed in the motor box. The model of the motor 2 is CT100L4. The motor shaft end of the motor 2 is coaxially connected with a coupling, and the outer output end of the coupling is coaxially connected. There are threaded rods 21; the center of the top of the bottom box 1 is longitudinally provided with a pair of sloping plates 24, and the outer ends of the two sloping plates 24 are fixedly connected to the front and rear end surfaces of the bearing housings respectively, and bearings are installed in the bearing housings; A pair of rectangular plate-shaped movable plates 28 are vertically suspended in the ...

Embodiment 2

[0035] Example 2: see Figure 5 , in this embodiment, the present invention also proposes a packaging method for a quick packaging machine for the finished product of the intelligent carbon skateboard, including the following steps:

[0036] Step 1, the motor 2, the first telescopic cylinder 13, the second telescopic cylinder 3, and the third telescopic cylinder 27 are all electrically connected to the battery 12;

[0037] Step 2, according to the width at both ends of different carbon slide plates 31, adjust the distance between the lifting plate 37 and the movable plate 28 by controlling the first telescopic cylinder 13 and the third telescopic cylinder 27; A connecting block drives the first sliding plate 15 to move laterally along the first slide rail 14, and then drives the sliding rod 16 and the sliding tube 25 to move laterally; controls the extension of the telescopic rod of the third telescopic cylinder 27, and the third connecting block and the sliding tube 25 Simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com