Polyaluminum silicate-cationic starch composite flocculant and preparation method thereof

A technology of cationic starch and composite flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of poor stability of polysilicate metal salt flocculant, limit the development of sewage treatment effect, and environmental protection impact, and achieve flocculation effect Obvious, extend the molecular chain, enhance the effect of adsorption bridging and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

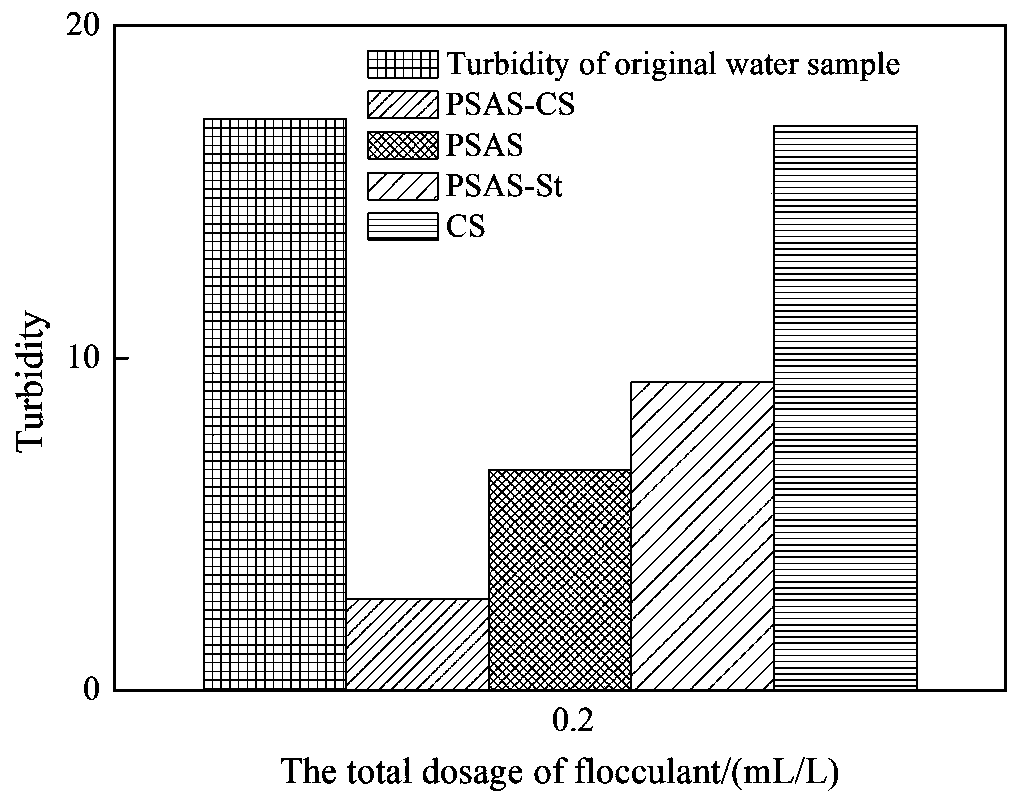

Image

Examples

Embodiment 1

[0028] Step 1: Preparation of Cationic Starch

[0029] Dissolve 10 g of starch in a mixture of 25 mL of water and ethanol, add 0.04 mol of cationic etherification agent (CHTPAC) under stirring, then slowly add 1 moL / L of NaOH solution as a catalyst, gelatinize at 70 ° C for 7 h, and the product is Precipitate in ethanol, wash and filter with suction, and dry under vacuum at 50°C to obtain a white powder, which is a cationic starch.

[0030] Step 2: Preparation of polyaluminum silicate-cationic starch composite flocculant

[0031] Specifically take the following steps:

[0032] (1) Configure 50 mL of 0.14 mol / L sodium silicate solution and adjust the pH to 3 with 30 wt% sulfuric acid solution, stir in a water bath for 2 hours, and leave to mature for 24 hours to obtain polysilicic acid;

[0033] (2) Prepare 0.4mol / L aluminum sulfate solution, mix 14.8mL aluminum sulfate solution with polysilicic acid and stir for 5min to obtain polyaluminum silicate solution;

[0034] (3) Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com