Method for separating and purifying neophytadiene in flue-cured tobacco leaves

A technology for separation and purification of neophytadiene, which is applied in the field of tobacco and can solve the problems of complex process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

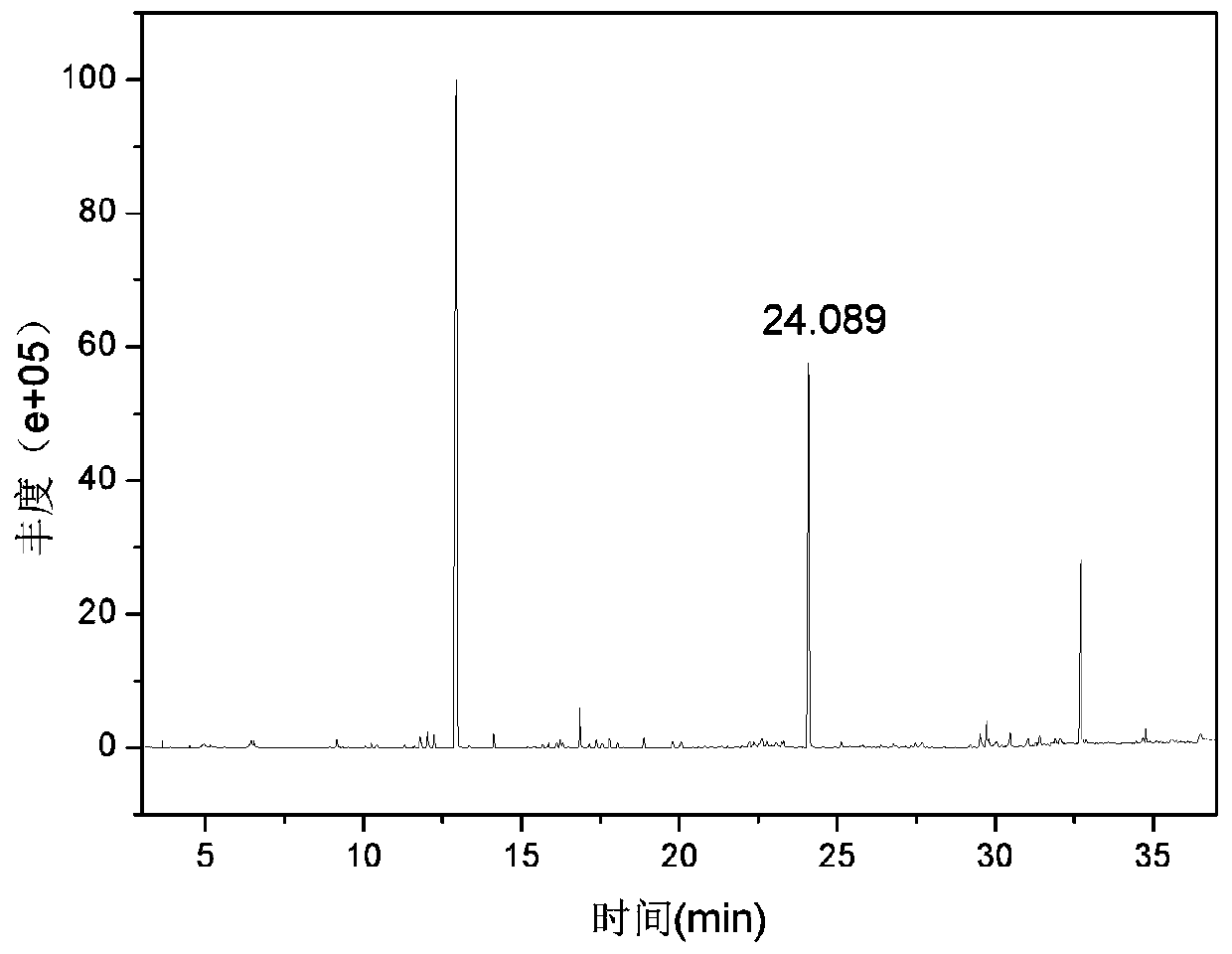

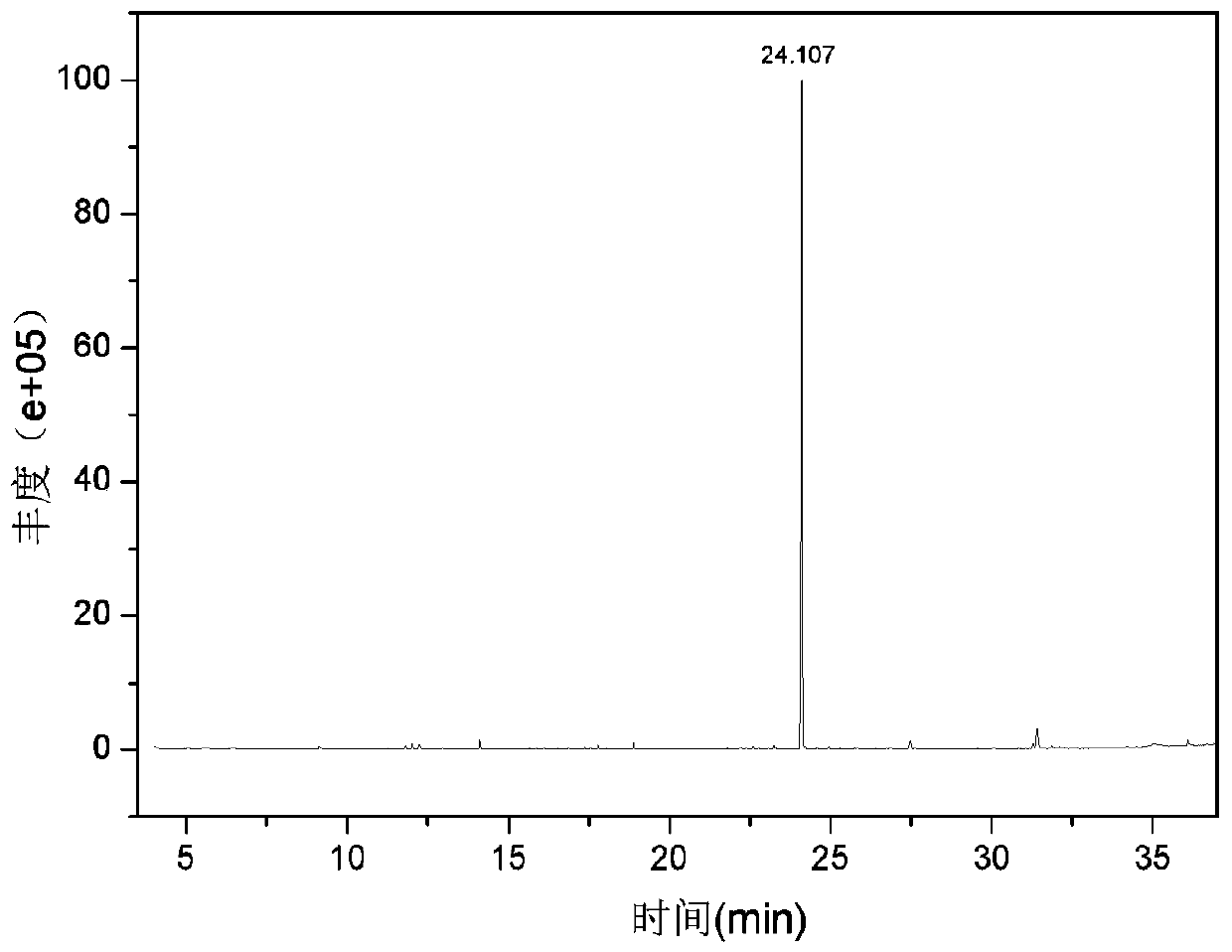

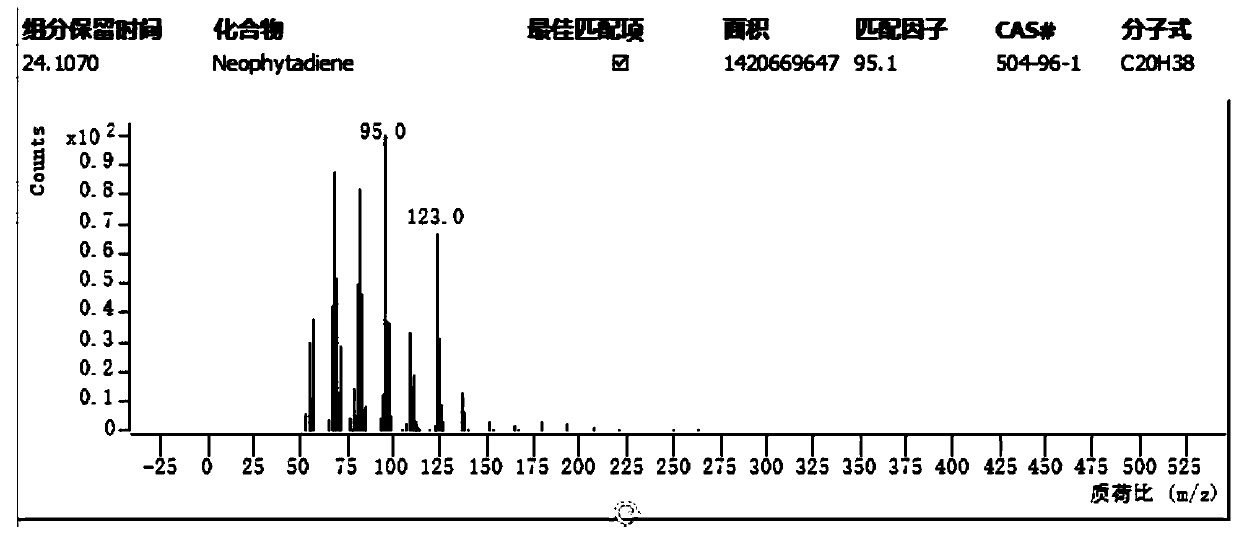

[0043] The fresh-cured tobacco leaves were dried at 45°C for 2 hours, then crushed and sieved in sequence to obtain fresh-cured tobacco leaves with 20-60 meshes. Weigh 60g of fresh-cured tobacco leaves with a particle size of 20-60 meshes and perform supercritical CO 2 Extraction to obtain 1.035g of the initial extract of new phytadiene; of which supercritical CO 2 The extraction pressure is 20MPa, the extraction temperature is 40°C, the carbon dioxide flow rate is 15g / min, the extraction time is 1h, the separation pressure is 5MPa, and the separation temperature is 40°C;

[0044] Weigh 0.1969g of the initial extract of new phytadiene, add 8mL of sodium hydroxide solution with a concentration of 0.05mol / L to obtain an alkaline extract;

[0045] Transfer the alkaline extract to the separatory funnel, and then add 8 mL of petroleum ether, n-hexane and n-pentane in a volume ratio of 2:1:1 to obtain a stripping agent. The obtained mixed solution is heated at 3000r / After shaking at min ...

Embodiment 2

[0047] The flue-cured tobacco leaves were dried at 50°C for 1.8 hours and then pulverized and sieved in order to obtain 20-60 mesh flue-cured tobacco leaves. Weigh 60g of the flue-cured tobacco leaves with a particle size of 20-60 mesh and perform supercritical CO 2 Extraction to obtain 1.274g of the initial extract of new phytadiene; of which supercritical CO 2 The extraction pressure is 25MPa, the extraction temperature is 45°C, the carbon dioxide flow rate is 20g / min, the extraction time is 1.5h, the separation pressure is 5MPa, and the separation temperature is 40°C;

[0048] Weigh 0.1969g of the initial extract of new phytadiene, add 4mL of sodium hydroxide solution with a concentration of 0.1mol / L to obtain an alkaline extract;

[0049] Transfer the alkaline extract to the separatory funnel, and then add 8 mL of the stripping agent obtained by mixing petroleum ether and n-pentane in a volume ratio of 3:1, and the resulting mixed solution is shaken at 3000r / min. After 4 minutes...

Embodiment 3

[0051] The flue-cured tobacco leaves were dried at 55°C for 2.2 hours and then pulverized and sieved to obtain 20-60 mesh flue-cured tobacco leaves. Weigh 60g of the flue-cured tobacco leaves with a particle size of 20-60 mesh and perform supercritical CO 2 Extraction to obtain 1.326g of new phytadiene initial extract; of which supercritical CO 2 The extraction pressure is 25MPa, the extraction temperature is 50°C, the carbon dioxide flow rate is 25g / min, the extraction time is 2h, the separation pressure is 5MPa, and the separation temperature is 40°C;

[0052] Weigh 0.1969g of the initial extract of new phytadiene, add 2mL of 0.2mol / L sodium hydroxide solution to obtain an alkaline extract;

[0053] Transfer the alkaline extract to the separatory funnel, and then add 8 mL of the stripping agent obtained by mixing petroleum ether and n-hexane in a volume ratio of 3:1, and the resulting mixed solution is oscillated at 3000r / min. After 5 minutes, let stand for stratification, take th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com