Steel box girder unloading construction method

A construction method and technology of steel box girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inability to achieve, achieve the effect of ensuring safety, reducing working time at heights, and reducing the risk of installers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

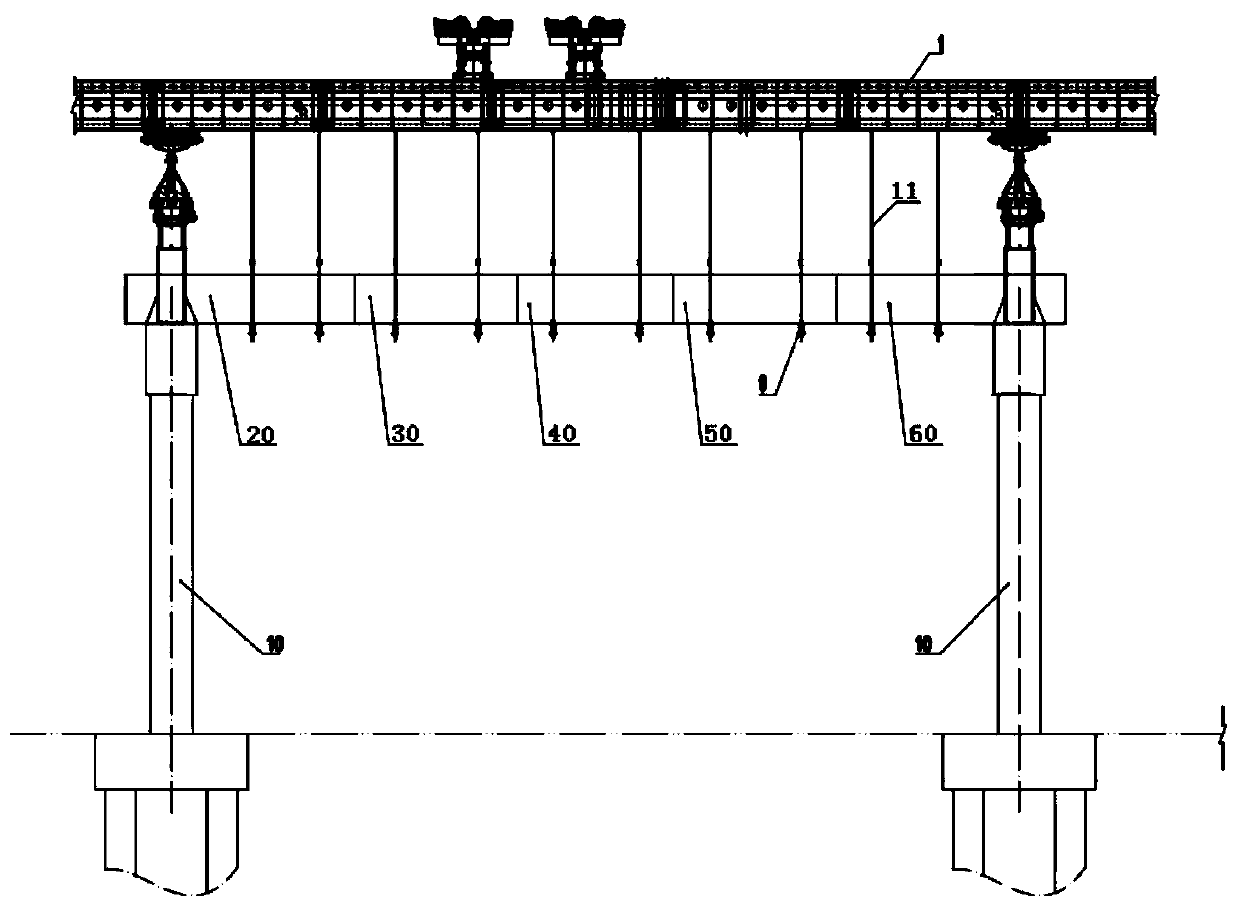

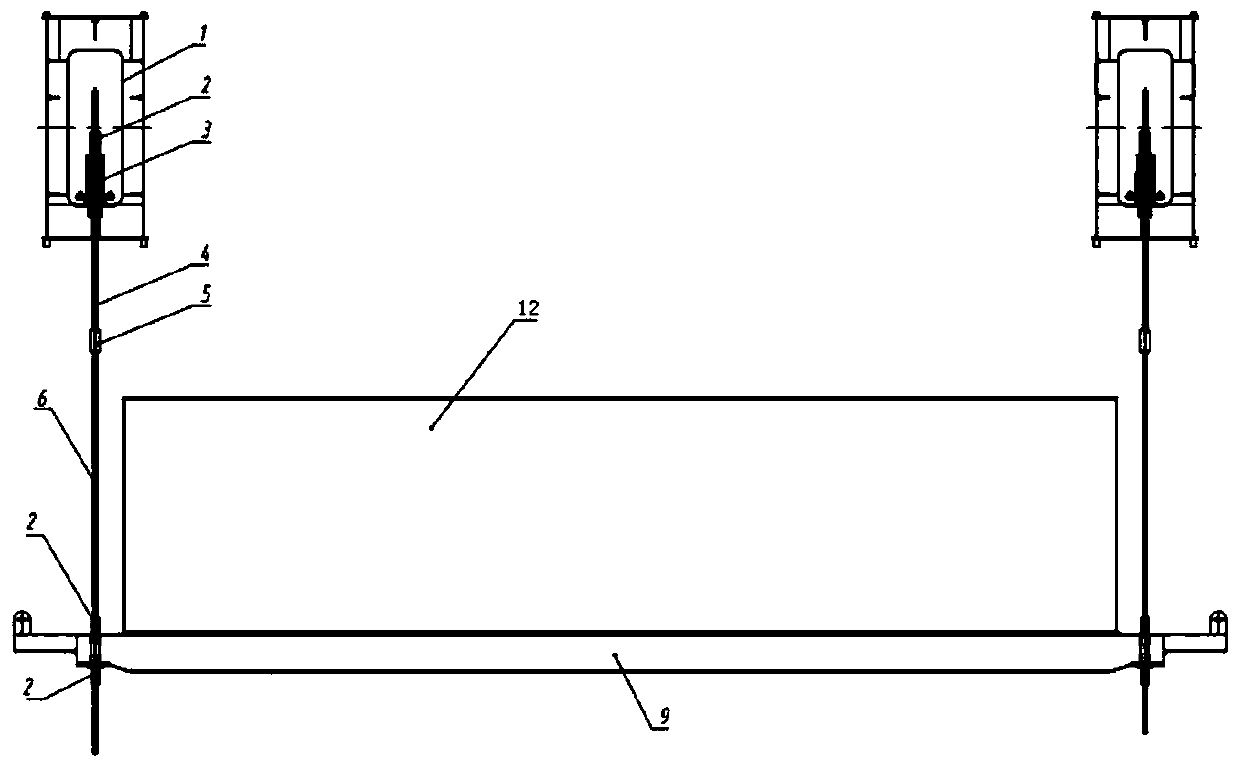

[0055] Such as figure 1 , figure 2 As shown, the unloading construction method of the steel box girder comprises the following steps:

[0056] Step 1, the preloading and unloading device 3 is placed on the segmental assembly bridge erecting machine 1, and the segmental assembly bridge erection machine 1 moves to the bridge pile 10;

[0057] Step 2, install the unloading device 3 on the segmental assembly bridge erecting machine 1;

[0058] Step 3, hoisting the segmental steel box girder 12;

[0059] Step 4, docking the upper boom 4 and the lower boom 6, and suspending the segmental steel box girder 12;

[0060] Step 5, assembling and welding the fixed segmental steel box girder 12 to form a full-span steel box girder and unload it;

[0061] In step 6, the bottom surface of the whole-span steel box girder is separated from the balance beam 9 .

[0062] Further, in step 1, the following steps are included:

[0063] Step 1.1, assemble the unloading device 3, the unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com