A mixed working medium high-pressure gas liquefaction and subcooling system

A technology of mixing working fluid and high-pressure gas, applied in the directions of liquefaction, refrigeration and liquefaction, cold treatment separation, etc., can solve the problems of poor matching effect and low efficiency of mixed working fluid, and achieve high utilization efficiency of cold energy, simple process structure, and avoidance of The effect of cooling temperature is too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

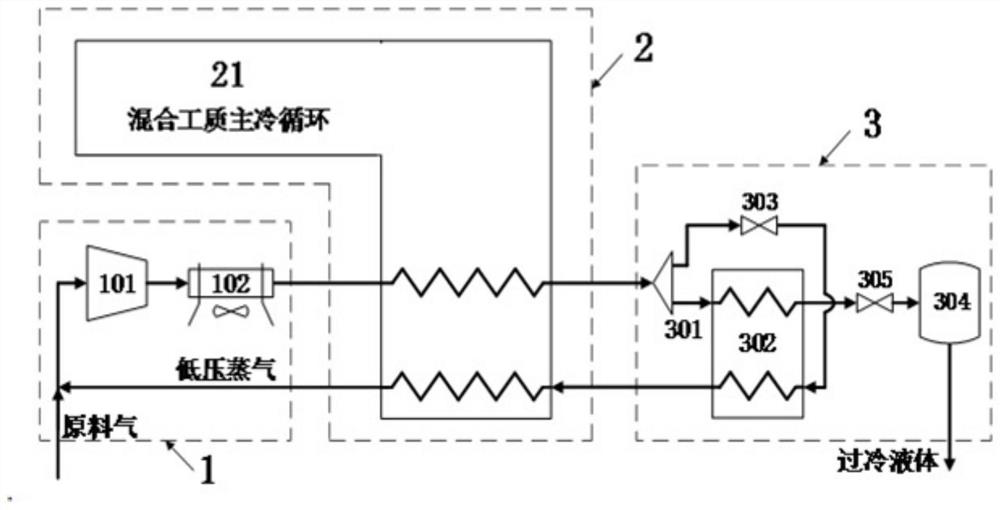

[0025] see figure 1 , is a mixed working medium high-pressure gas liquefaction and supercooling system provided in Embodiment 1 of the present invention, including: a gas pressurization unit 1 , a mixed working medium refrigerator unit 2 , and a supercooling unit 3 . in:

[0026] The gas booster unit 1 includes a gas compressor 101 and an aftercooler 102 .

[0027] It can be understood that a multi-stage compressor can be used to mix the low-pressure feed gas and low-pressure steam to pressurize to 10-30 bar.

[0028] The mixed working medium refrigerator unit 2 includes a mixed working medium main refrigeration cycle 21 .

[0029] The subcooling unit 3 includes a distributor 301 , a subcooling heat exchanger 302 , a main throttling element 303 , a liquid storage tank 304 and a liquefied gas throttling element 305 .

[0030] The working mode of the mixed working medium high-pressure gas liquefaction and supercooling system provided by the above-mentioned embodiment 1 of the...

Embodiment 2

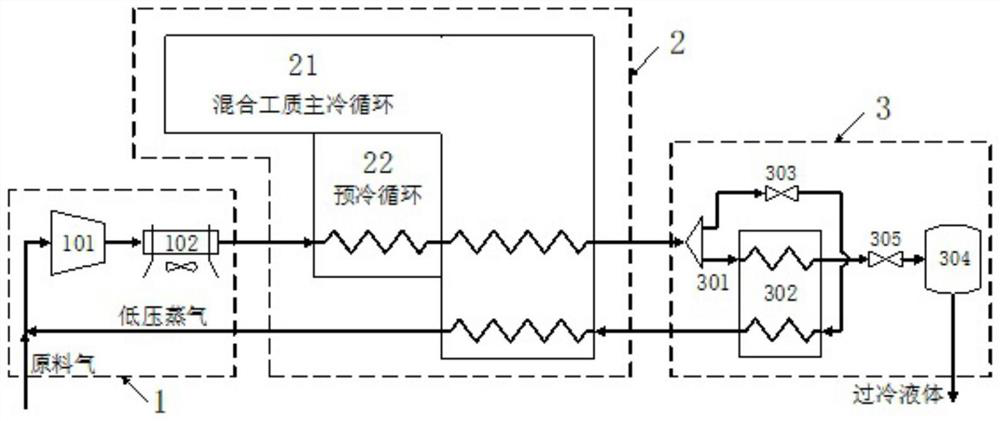

[0035] see figure 2 , is a schematic structural diagram of the mixed working medium high-pressure gas liquefaction and supercooling system provided by Embodiment 2 of the present invention. For the convenience of description, only the relevant drawings are described below.

[0036] The difference from the above-mentioned embodiment 1 is that the mixed working medium refrigerator unit provided in the second embodiment of the present invention also includes a pre-cooling cycle 22, which pre-cools the high-pressure feed gas and the mixed working medium; the pre-cooling The cycle 22 can adopt configurations such as a vapor compression refrigeration cycle, an absorption refrigeration cycle, and a commercial chiller.

[0037] For other working methods, refer to Embodiment 1, which will not be repeated here.

[0038]The mixed working medium high-pressure gas liquefaction and supercooling system provided by the above-mentioned embodiment 2 of the present invention uses a precooling ...

Embodiment 3

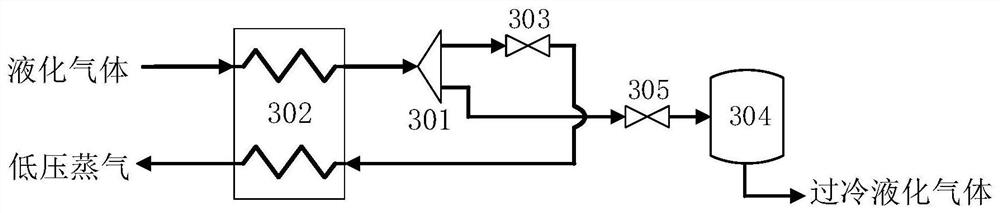

[0040] see image 3 , is a schematic structural diagram of the mixed working medium high-pressure gas liquefaction and supercooling system provided by Example 4 of the present invention.

[0041] The liquefied gas formed by cooling the high-pressure feed gas through the mixed working medium refrigerator unit 2 is firstly subcooled to -150°C to -190°C through the subcooling heat exchanger 302, and then passed through the gas distributor 301 separates a small stream of liquefied gas, the small stream of liquefied gas is throttled by the main throttling element 303 to close to normal pressure and cooled to below -152°C to -192°C, and then enters the subcooling heat exchanger 302. Liquefaction provides cooling capacity and forms low-pressure steam, and then returns to the gas compressor 101 after being reheated by the mixed working medium refrigerator unit 2 and recovering cooling capacity, and continues to participate in liquefaction;

[0042] The remaining liquefied gas separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com