A system for producing liquid oxygen and liquid nitrogen by cascading LNG cold energy

A cold energy and cascade technology, which is applied in the system field of cascade utilization of LNG cold energy to produce liquid oxygen and liquid nitrogen, can solve the problems of LNG cold energy waste and air separation oxygen production energy consumption, etc., to save cold energy input and improve Cold energy utilization efficiency and the effect of reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

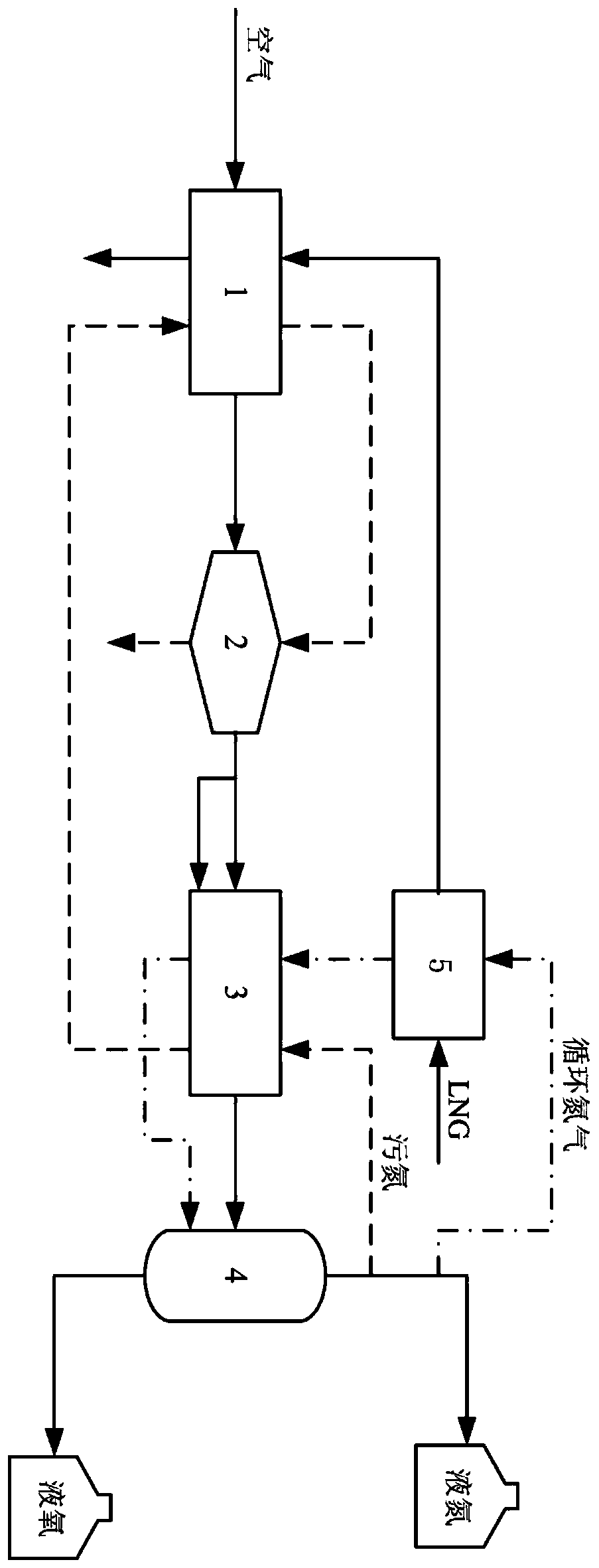

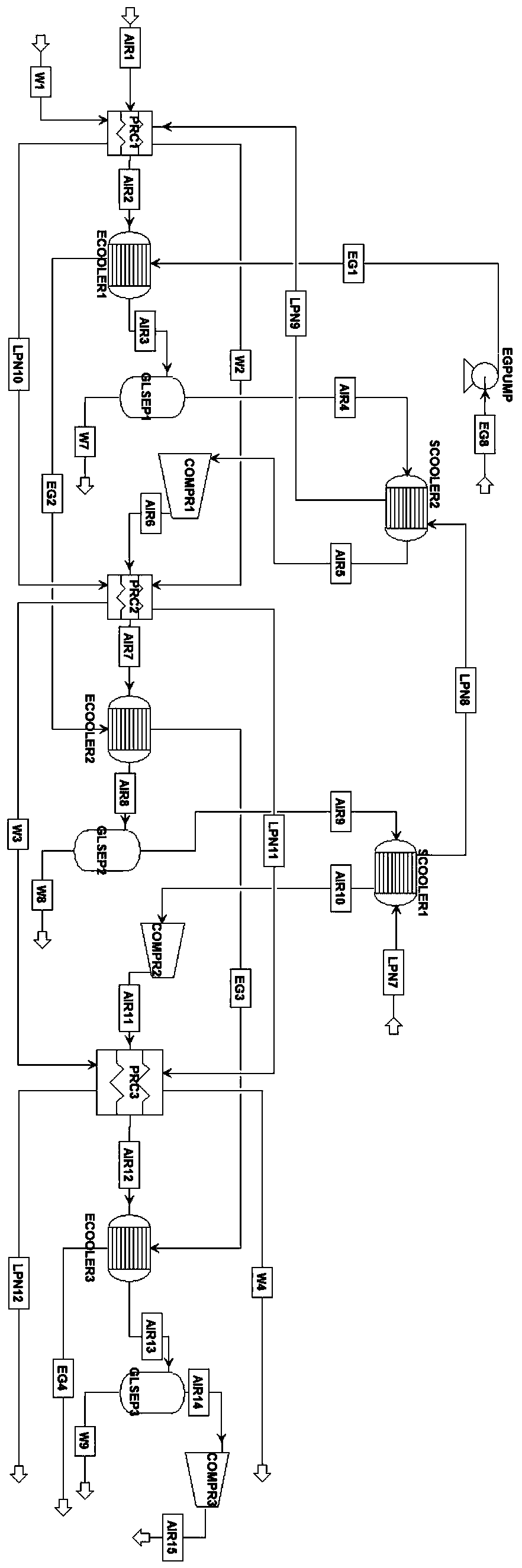

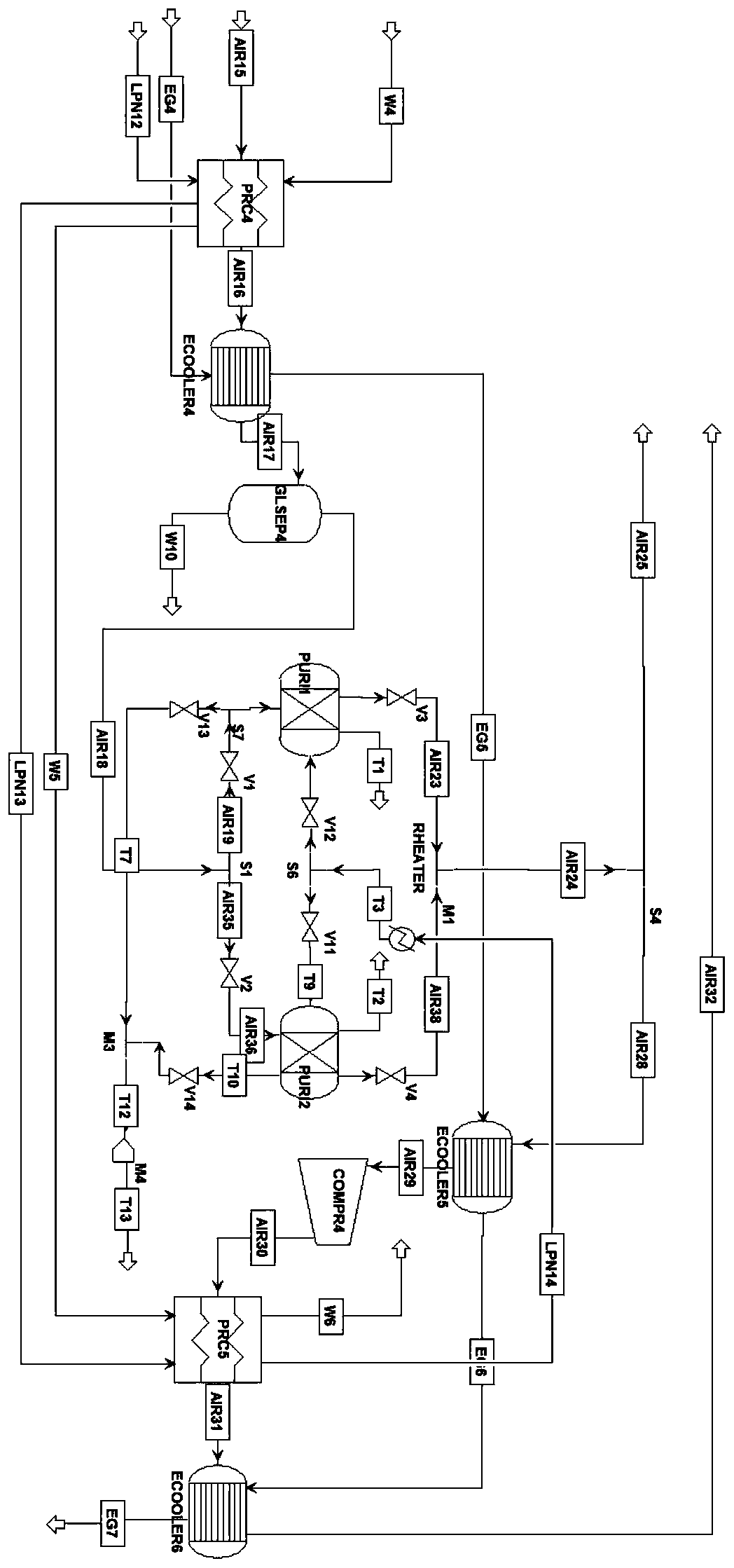

[0055] Such as figure 1 As shown, a cascade system for producing liquid oxygen and liquid nitrogen by using LNG cold energy, including air multi-stage pre-cooling compression module 1, air purification module 2, main heat exchange module 3, rectification module 4 and LNG heat exchange module 5 ; Wherein, the air multi-stage pre-cooling compression module 1 is used to perform multi-stage compression and cooling to the medium pressure of the raw material air, and the compressed and cooled medium-pressure air is purified and divided by the air purification module 2, and a part of it is passed into The main heat exchange module 3 is used for cryogenic cooling; the other part is pressurized into high-pressure air, and then passed into the main heat exchange module for cryogenic liquefaction.

[0056] The main component of feed air in the present invention is N 2 and O 2 , the temperature is around 20°C. The input LNG is liquid natural gas with a pressure of 0.1MPa and a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com