Liquid core angle sensor

An angle sensor and liquid core technology, applied in the field of flexible wearable sensing, can solve the problems of limiting the application of optical fiber flexible sensors, low stretchability, poor flexibility, etc., so as to save the process of sealing the hose and reduce the production cost , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

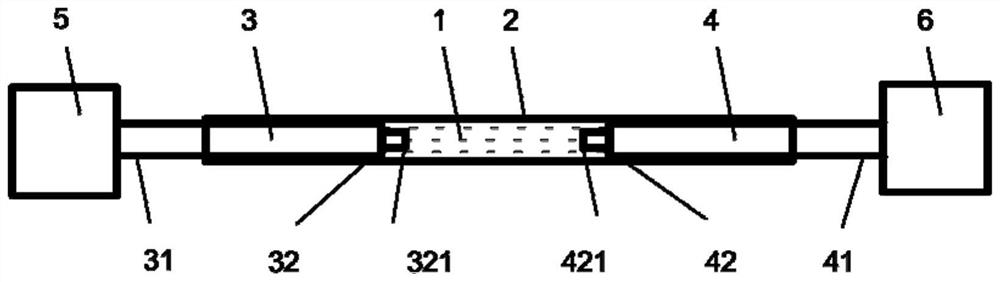

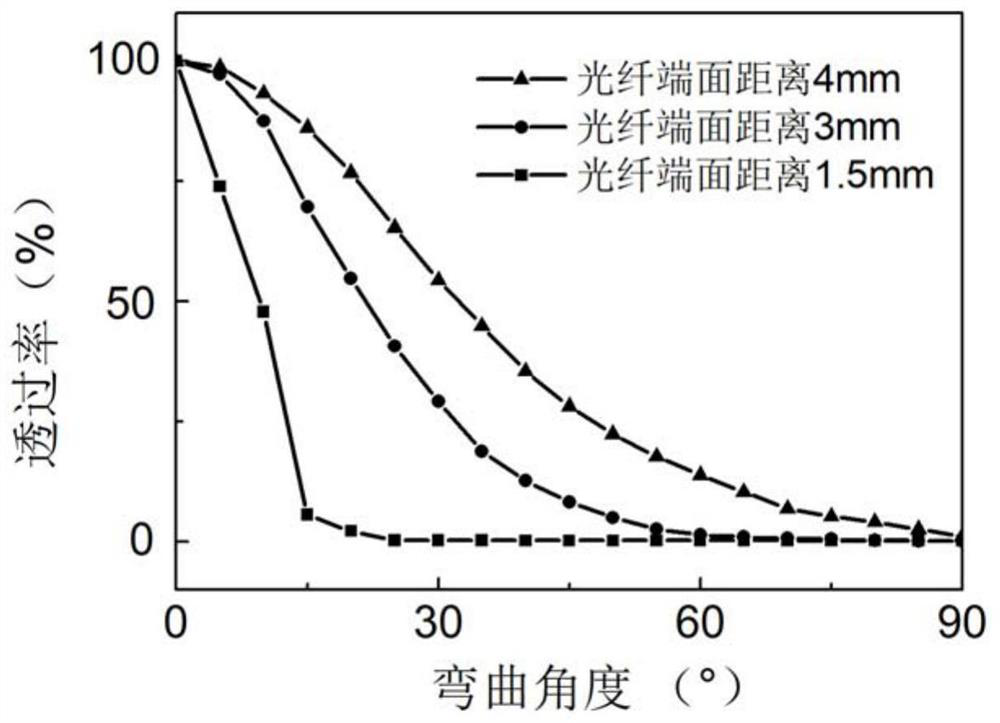

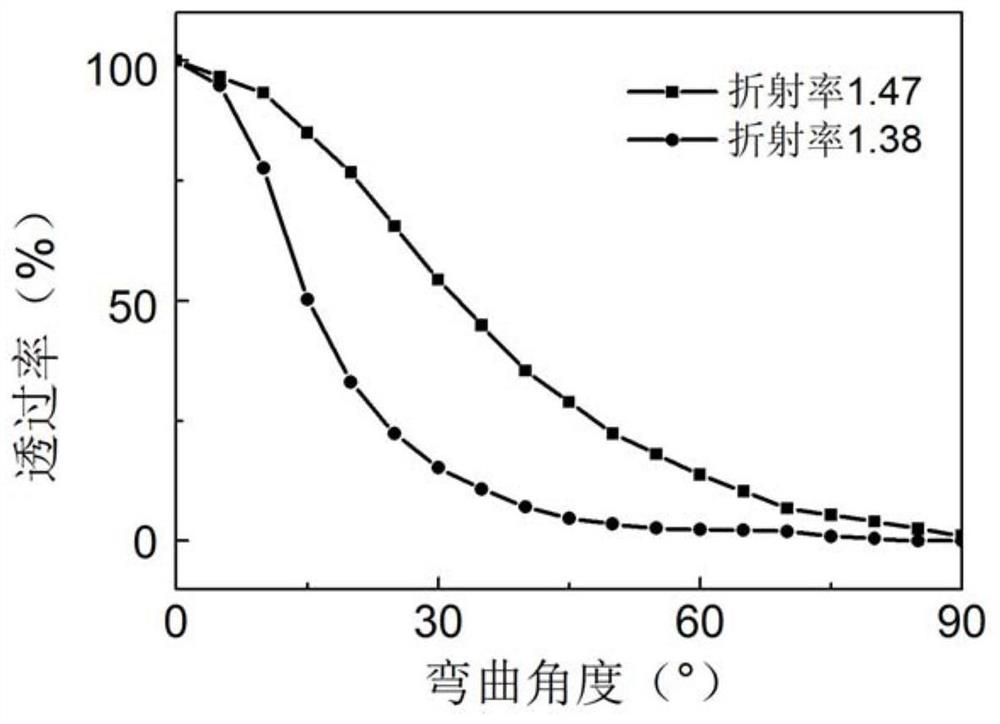

[0018] Such as figure 1 As shown, the liquid core angle sensor of the present invention includes a closed hose 2 filled with liquid 1 and two optical fibers (first optical fiber 3 and second optical fiber 4). "Liquid core" means that the hose 2 is filled with the liquid 1 . Because the hose 2 is filled with the liquid 1, the deformation of the liquid caused by the change of the bending angle of the sensing position can cause the change of the signal light transmittance, so the angle sensing can be realized by measuring the loss of the signal light caused by the deformation of the sensing position . The refractive index of liquid 1 is less than or equal to the refractive index of hose 2 . Generally, the optical fiber can be a silica optical fiber or a polymer optical fiber. In the present invention, one end 31 of the first optical fiber is placed outside the hose 2 to connect to the light source 5 ; one end 41 of the second optical fiber is placed outside the hose 2 to conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com