Lithium secondary battery and manufacturing method thereof

A lithium secondary battery and electrolyte technology, applied in secondary battery, electrolyte storage battery manufacturing, lithium storage battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

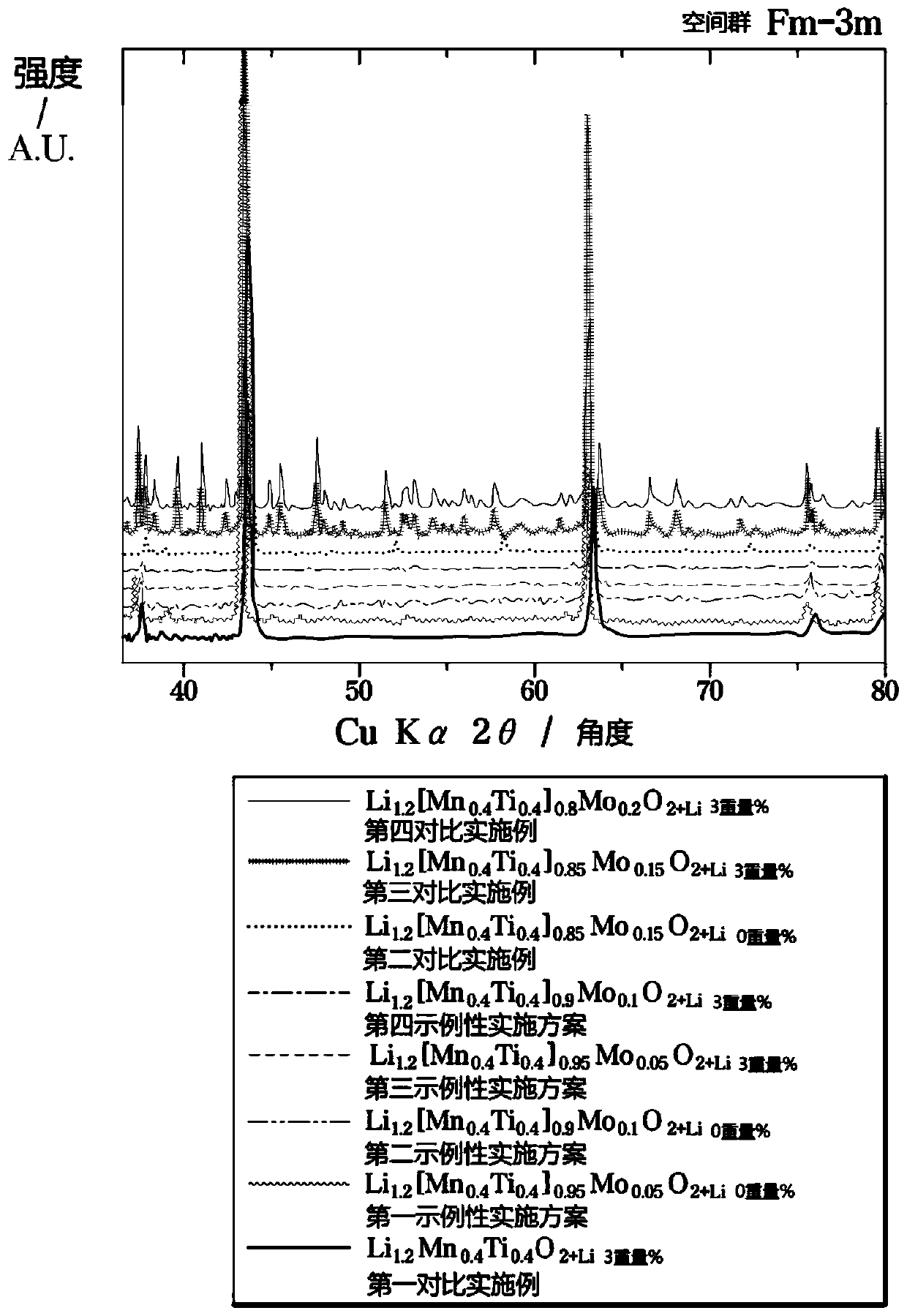

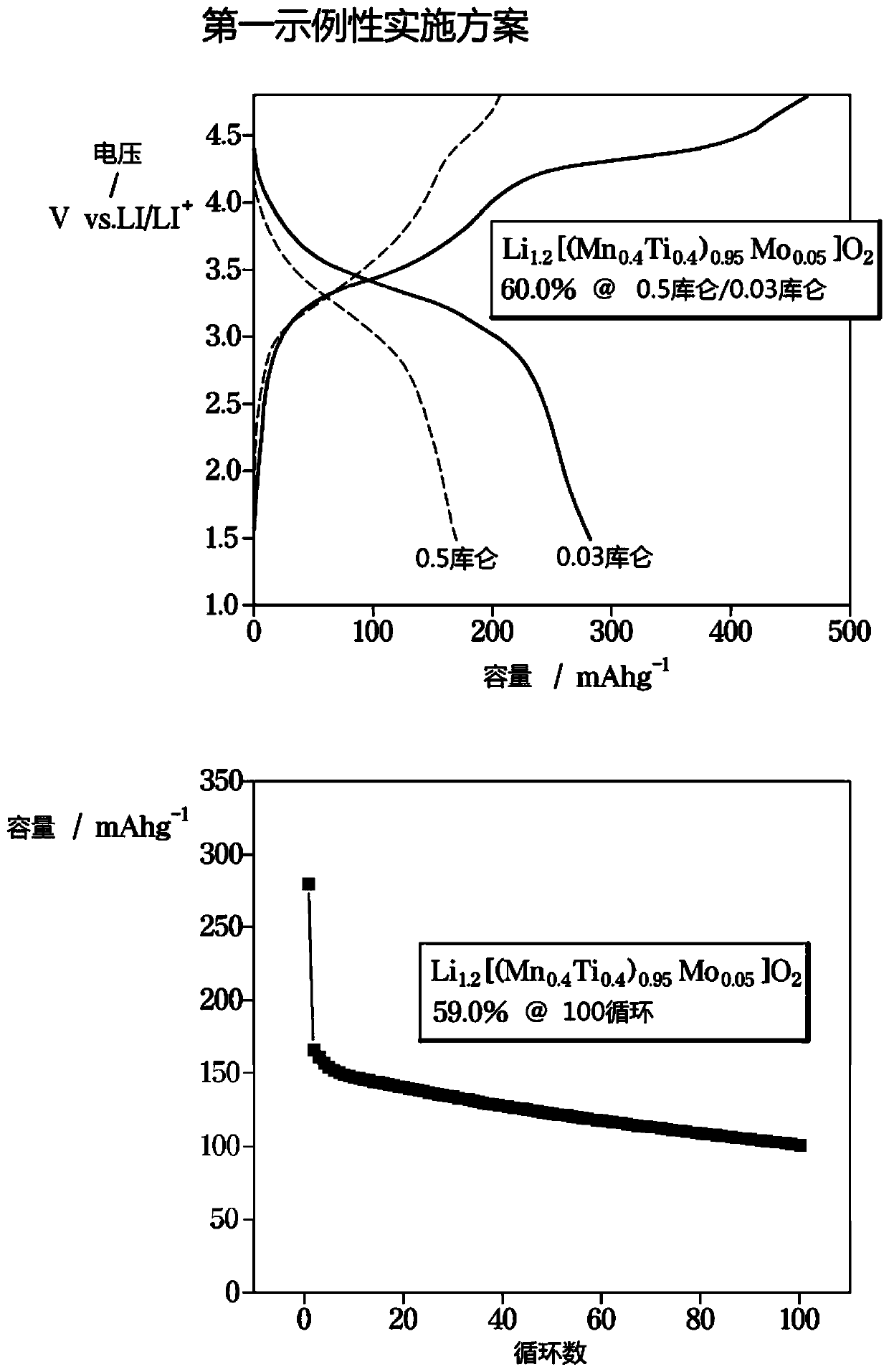

[0055] Example 1: First Exemplary Embodiment

[0056] The first exemplary embodiment uses Li 2 CO 3 , Mn 2 o 3 (by calcining MnCO 3 Synthesis), TiO 2 and Mo 2 o 5 Perform ball milling with absolute ethanol solvent. According to a first exemplary embodiment, according to Li 1.2 [(Mn 0.4 Ti 0.4 ) 0.95 Mo 0.05 ]O 2 The composition of the additive material. For ball milling, a 5 g amount of 10 mm size ZrO was introduced 2 Ball, ZrO of 5mm size for 10g 2 Balls and 4g of 1mm size ZrO 2 ball. Ball milling was carried out in 17 groups, each time at a speed of 300 rpm for 15 minutes. After ball milling, the cathode active material was washed with ethanol, dried and pelletized. Then, the cathode active material was calcined at a temperature of 900° C. for 12 hours in an Ar atmosphere, thereby obtaining cathode active material powder.

Embodiment 2

[0057] Example 2: Second Exemplary Embodiment

[0058] A cathode active material powder was obtained in the same manner as in Example 1, except that molybdenum had a ratio of 0.1, thereby obtaining Li 1.2 [(Mn 0.4 Ti 0.4 ) 0.9 Mo 0.1 ]O 2 .

Embodiment 3

[0059] Example 3: Third Exemplary Embodiment

[0060] A cathode active material powder was obtained in the same manner as in the first exemplary embodiment except that an excess amount of lithium was added in an amount of 3% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com