Environment-friendly fireproof PA6 composite material and preparation method thereof

A composite material and environment-friendly technology, which is applied in the field of environment-friendly fireproof PA6 composite material and its preparation, can solve the problems of health injuries of drivers and passengers in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

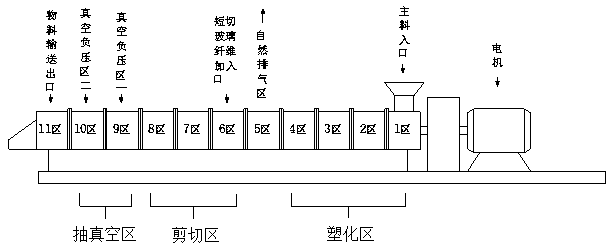

Method used

Image

Examples

specific Embodiment 1

[0024] Specific embodiment one, an environment-friendly fireproof PA6 composite material is characterized in that it comprises the following raw materials in parts by weight: 56.5 parts of polyamide PA6 resin; 20 parts of chopped glass fiber; 18 parts of flame retardant; synergistic flame retardant 5 parts; 0.5 parts of anti-dripping agent PTFE; 0.5 parts of high-adsorption deodorization extractant; 0.1 parts of antioxidant; 0.1 part of light stabilizer.

[0025] The viscosity of the polyamide PA6 resin is 2.0 pas; the flame retardant is a brominated polystyrene resin with a molecular weight between 35000-45000; the synergistic flame retardant is antimony trioxide; the high The active ingredients in the adsorption and deodorization extractant include vermiculite and activated carbon.

[0026] The preparation method of the environment-friendly fireproof PA6 composite material is characterized in that the steps are: the following raw materials in parts by weight,

[0027] (1) 5...

specific Embodiment 2

[0030] Specific embodiment two, an environment-friendly fireproof PA6 composite material is characterized in that it comprises the following raw materials in parts by weight: 56 parts of polyamide PA6 resin; 20 parts of chopped glass fiber; 18 parts of flame retardant; synergistic flame retardant 5 parts; 0.5 parts of anti-dripping agent PTFE; 1 part of high-adsorption deodorant extractant; 0.1 part of antioxidant; 0.1 part of light stabilizer.

[0031] The viscosity of the polyamide PA6 resin is 2.0 pas; the flame retardant is a brominated polystyrene resin with a molecular weight between 35000-45000; the synergistic flame retardant is antimony trioxide; the high The active ingredients in the adsorption and deodorization extractant include vermiculite and activated carbon.

[0032] The preparation method of the environment-friendly fireproof PA6 composite material is characterized in that the steps are: the following raw materials in parts by weight,

[0033] (1) 56 parts of...

specific Embodiment 3

[0036] Specific embodiment three, an environment-friendly fireproof PA6 composite material is characterized in that it comprises the following raw materials in parts by weight: 55 parts of polyamide PA6 resin; 20 parts of chopped glass fiber; 18 parts of flame retardant; synergistic flame retardant 5 parts; 0.5 parts of anti-dripping agent PTFE; 2 parts of high-adsorption deodorant extractant; 0.1 part of antioxidant; 0.1 part of light stabilizer.

[0037] The viscosity of the polyamide PA6 resin is 2.0 pas; the flame retardant is a brominated polystyrene resin with a molecular weight between 35000-45000; the synergistic flame retardant is antimony trioxide; the high The active ingredients in the adsorption and deodorization extractant include vermiculite and activated carbon.

[0038] The preparation method of the environment-friendly fireproof PA6 composite material is characterized in that the steps are: the following raw materials in parts by weight,

[0039] (1) 55 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com