based on co 2 /n 2 Preparation method of paraffin granules of switching emulsion and application of paraffin granules

A paraffin and emulsion technology, which is applied in the application of paraffin particles and the preparation of paraffin particles, can solve the problems of difficulty in preparing micron-scale paraffin particles, large particle size of paraffin particles, residual organic solvents, etc., so as to save production labor costs, The effect of uniform particle size distribution and improved dynamic-plastic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Based on the above technical problems, the inventor provides a CO-based 2 / N 2 The method for preparing paraffin particles of switch emulsion, which specifically includes the following steps: S1) Prepare the oil phase: add paraffin to N,N dimethylcyclohexylamine, and stir until the paraffin is completely dissolved, then add emulsifier A and stir until completely dissolved , to obtain the oil phase;

[0040] S2) Prepare the water phase: add the emulsifier B to deionized water, stir until the emulsifier B is completely dissolved, and obtain the water phase;

[0041] S3) preparing O / W emulsion: after mixing the oil phase and the water phase, stirring and emulsifying to obtain an O / W emulsion;

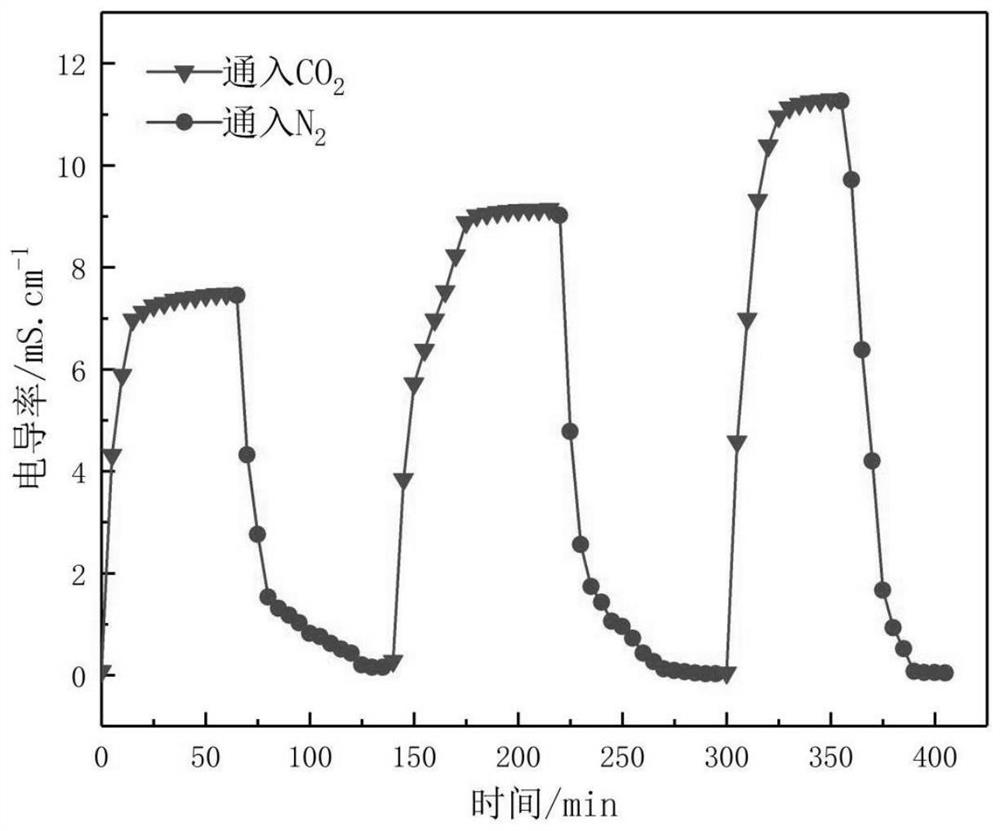

[0042] S4) Preparation of paraffin particles: carbon dioxide is introduced into the O / W emulsion, the paraffin particles are precipitated, and the paraffin particles and protonated solvent are obtained after centrifugation;

[0043] S5) Recycling: Nitrogen gas is passed into the ...

Embodiment 1

[0053] S1) Dissolve 12.5g of paraffin completely in 37.5g of N,N dimethylcyclohexylamine, then add 2.208g of Span-80, and stir until Span80 is completely dissolved to form an oil phase;

[0054] S2) Dissolving 1.472g of Tween-80 in deionized water to form an aqueous phase;

[0055] S3) under stirring conditions, slowly add the oil phase into the water phase, so that the concentration of emulsifier A + emulsifier B is 8%, forming an O / W emulsion;

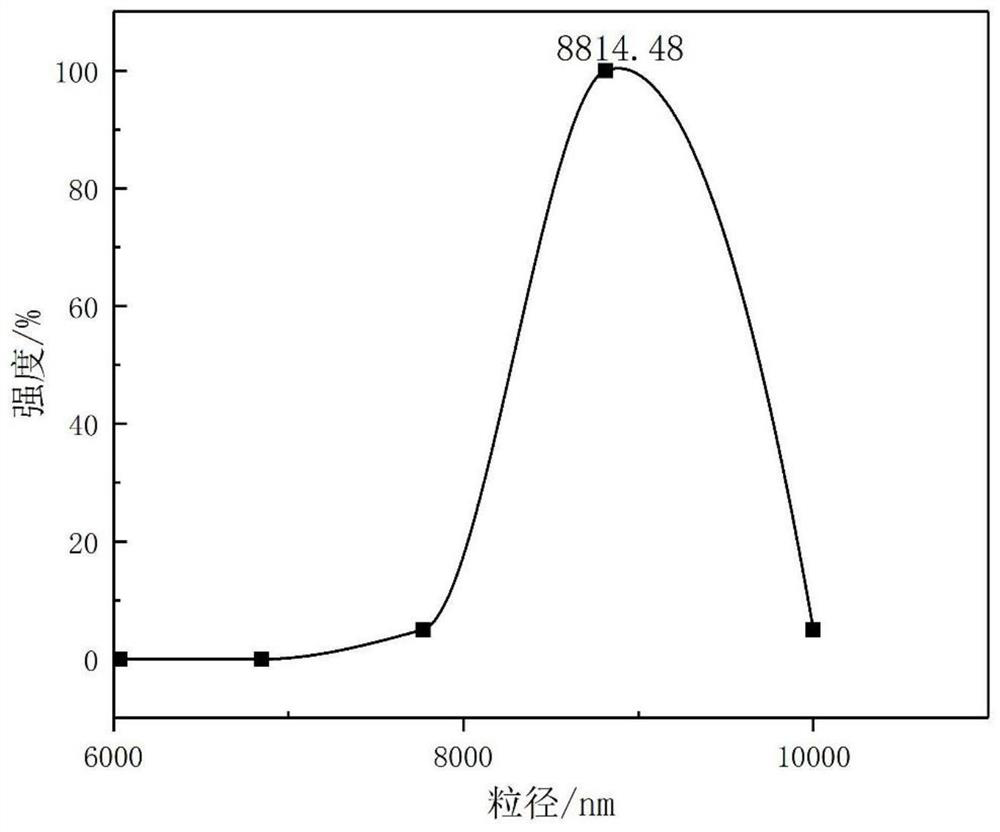

[0056] S4) Pass CO into the emulsion 2 , the solvent N,N dimethylcyclohexylamine was dissolved in water, and centrifuged to obtain paraffin particles;

[0057] S5) The centrifuged supernatant was passed into N 2 , the supernatant is stratified into solvent and emulsifier aqueous solution, and the solvent and emulsifier aqueous solution are separated by a separatory funnel, and continue to be put into recycling.

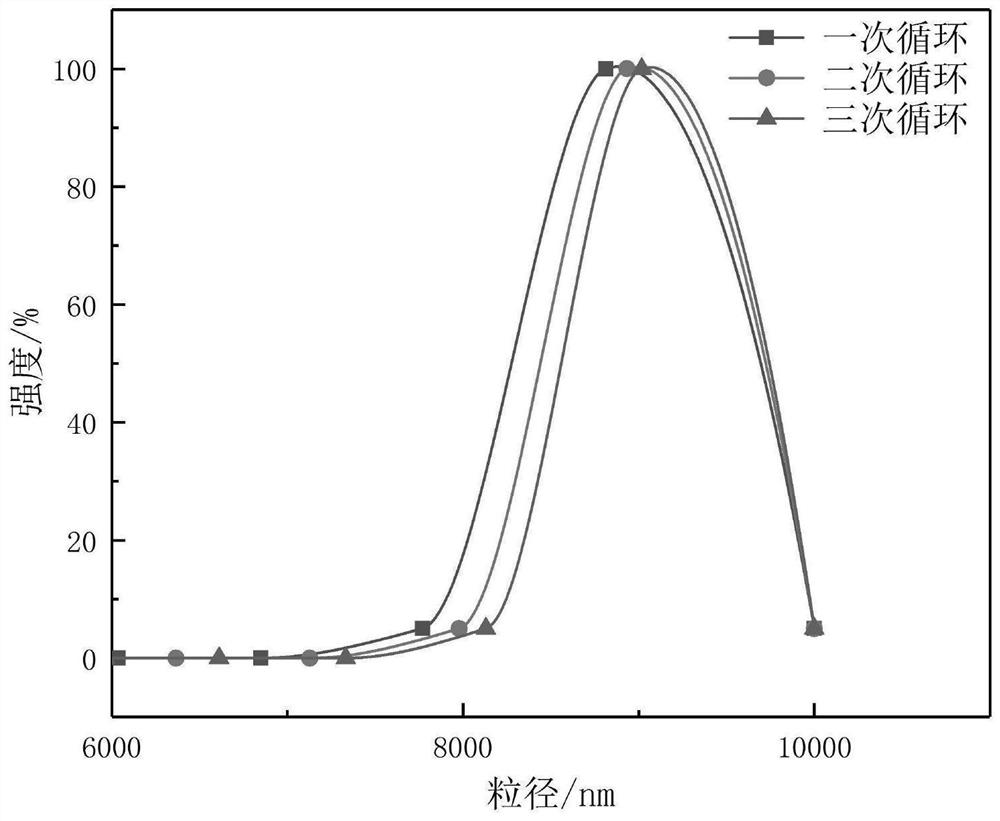

[0058] recycle:

[0059] The solvent and emulsifier aqueous solution obtained after the first preparation above are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com