Device and method for measuring dielectric constant and metal conductivity of copper-clad plate

A technology of dielectric constant and metal conductance, which is applied in the field of microwave measurement, can solve problems such as difficult to meet the demand, uncertain metal conductivity, neglect of metal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

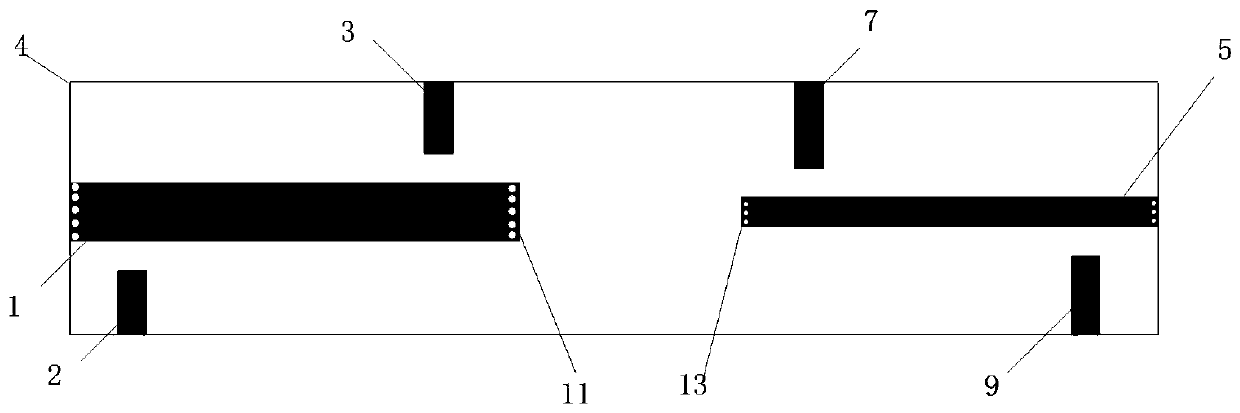

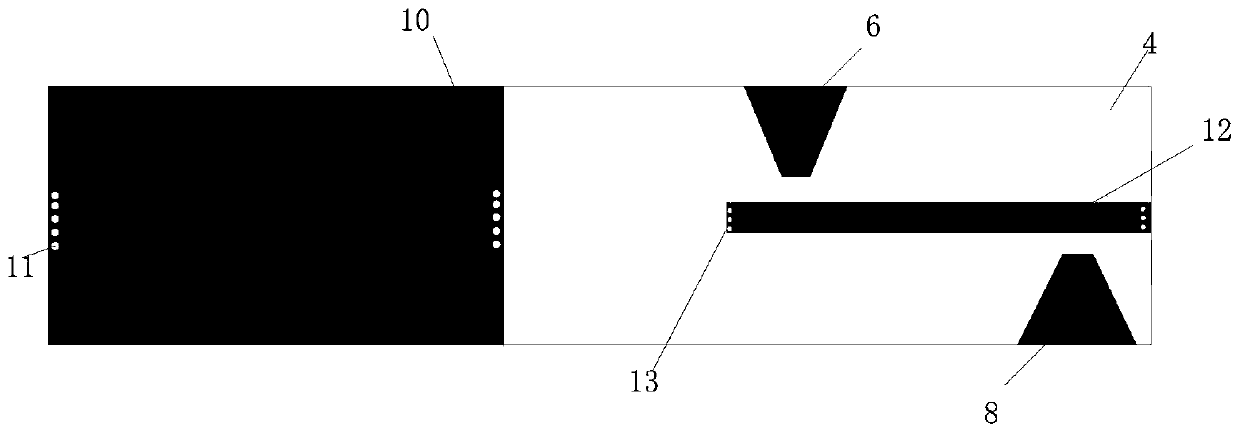

[0129] Such as figure 1 As shown, a microstrip resonant cavity and a parallel double-line resonant cavity are arranged on the copper clad board 4 with a height of 0.5 mm, a width of 10 mm, and a length of 200 mm. The width w of the conduction band 1 of the microstrip line resonator is 2 mm, and the width w of the conduction band 5 on one side of the parallel double-line resonator and the conduction band 12 on the other side of the parallel double-line resonator is 1 mm. The conduction band 1 of the microstrip line resonator, the conduction band 5 on one side of the parallel double lines, and the conduction band 12 on the other side of the parallel double lines all have a thickness t of 0.035 mm and a length L of 73 mm. Depend on figure 2 It can be seen that the microstrip part has a conductor ground 10 with a width of 10mm and a length of 73mm, and the microstrip resonant cavity is fed through a feeding microstrip line 2 and another feeding microstrip line, and the parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com