Power amplifier case with adjustable local heat dissipation capacity

A heat-dissipating, adjustable technology, used in electrical equipment structural parts, cooling/ventilation/heating renovation, chassis/cabinet/drawer parts, etc. The problems such as the accumulation of differences and complex processing can be achieved to ensure the electromagnetic sealing performance, reduce the flow resistance, and improve the heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

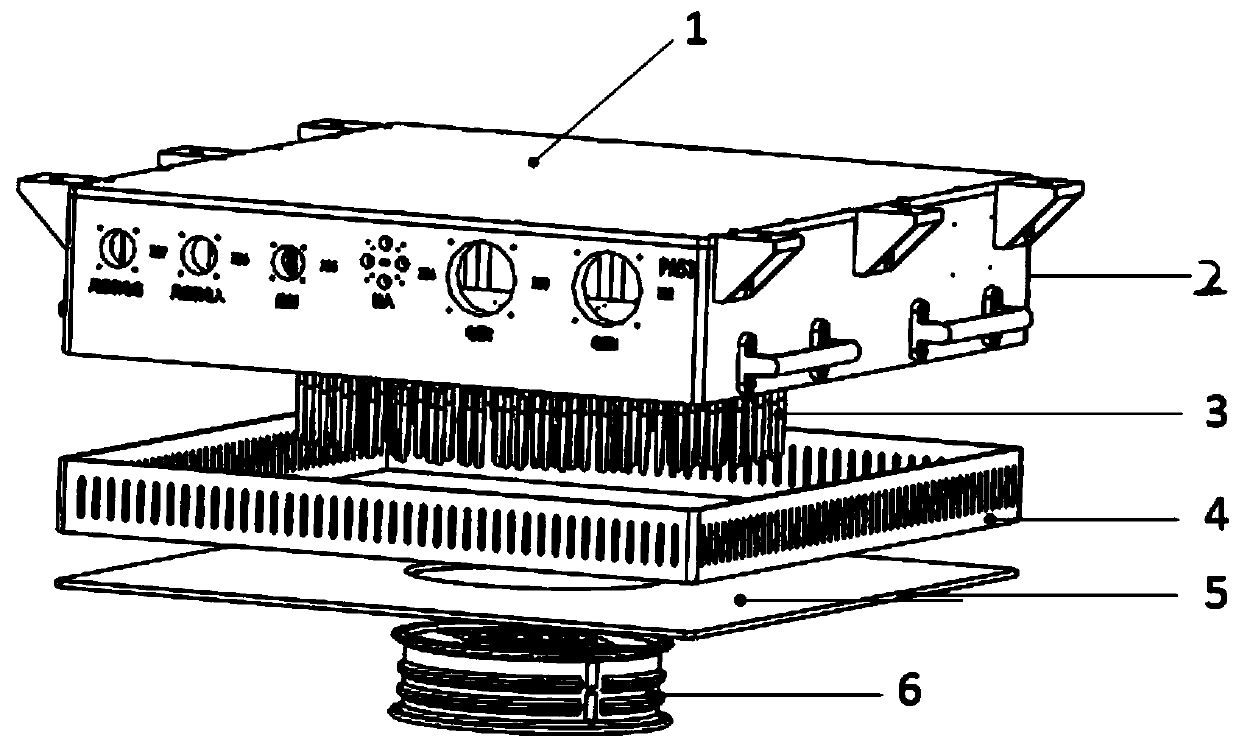

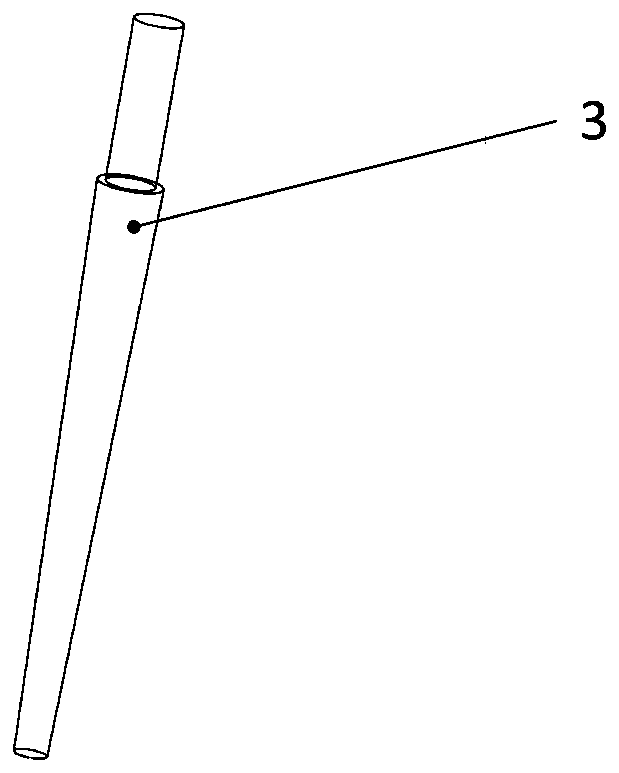

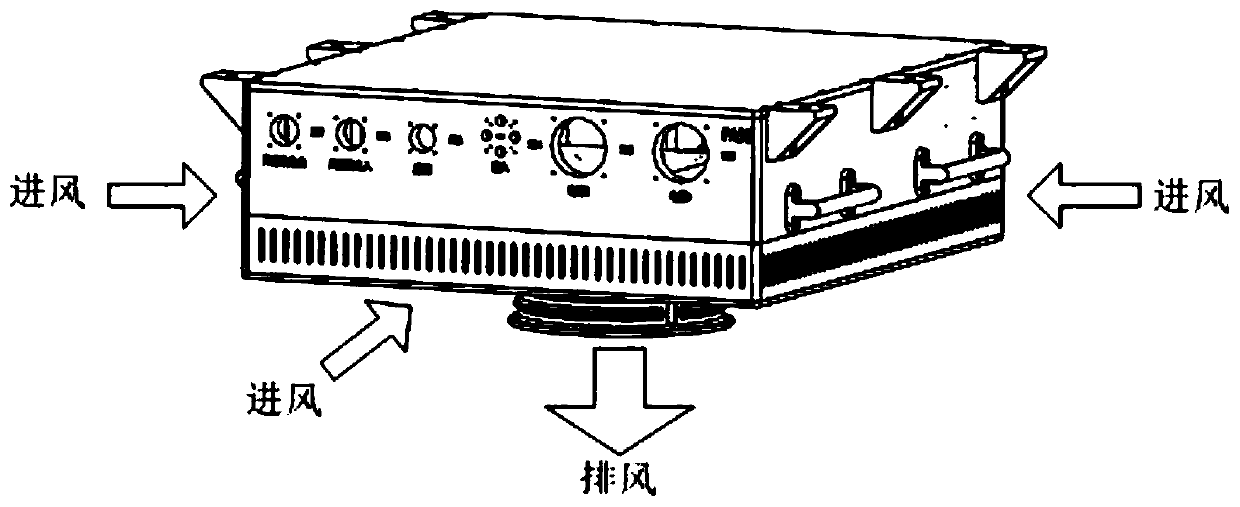

[0022] A power amplifier case with adjustable local heat dissipation capacity, which includes an upper equipment chamber and a lower heat dissipation chamber, the equipment chamber and the heat dissipation chamber are separated by a mounting plate; a plurality of power tubes are arranged on one side of the equipment chamber of the mounting plate Mounting position, one side of the heat dissipation cavity of the mounting plate, at the corresponding position of each power tube installation position, there is at least one connection hole; at least one connection hole in the heat dissipation cavity is provided with a heat dissipation column, and the heat dissipation column and the connection hole Threaded connection; a vent is provided on the side wall of the heat dissipation chamber, and a heat dissipation fan is provided on the bottom plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com