Pneumatic-transport lobster bait casting machine applied to deep sea net cage

A deep-sea net cage and pneumatic conveying technology, which is applied in the field of lobster farming, can solve the problems of different density of feed, inaccurate feed measurement of bait feeding system, and decontamination, so as to achieve accurate driving of lobsters, easy driving of lobsters, and improvement of utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

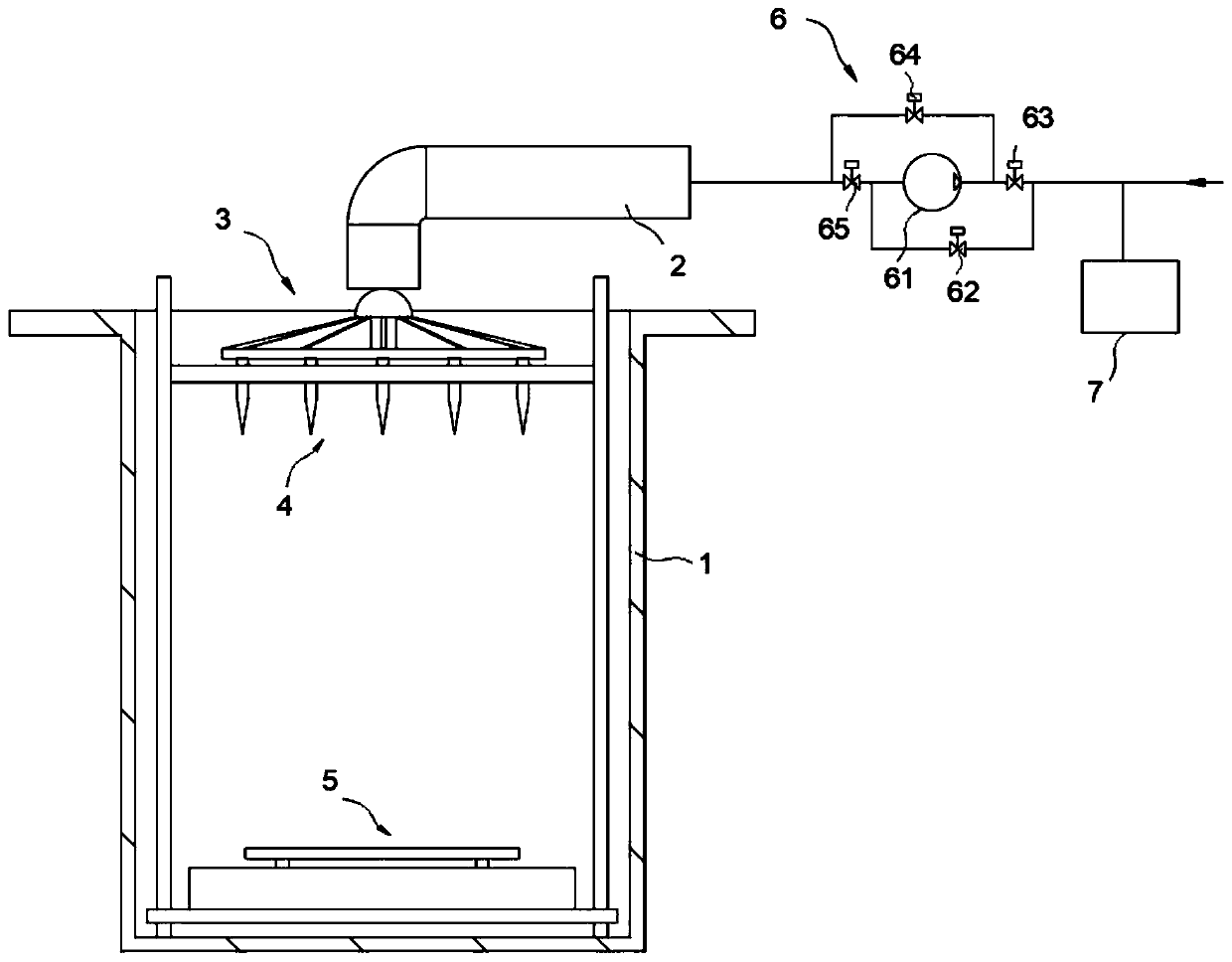

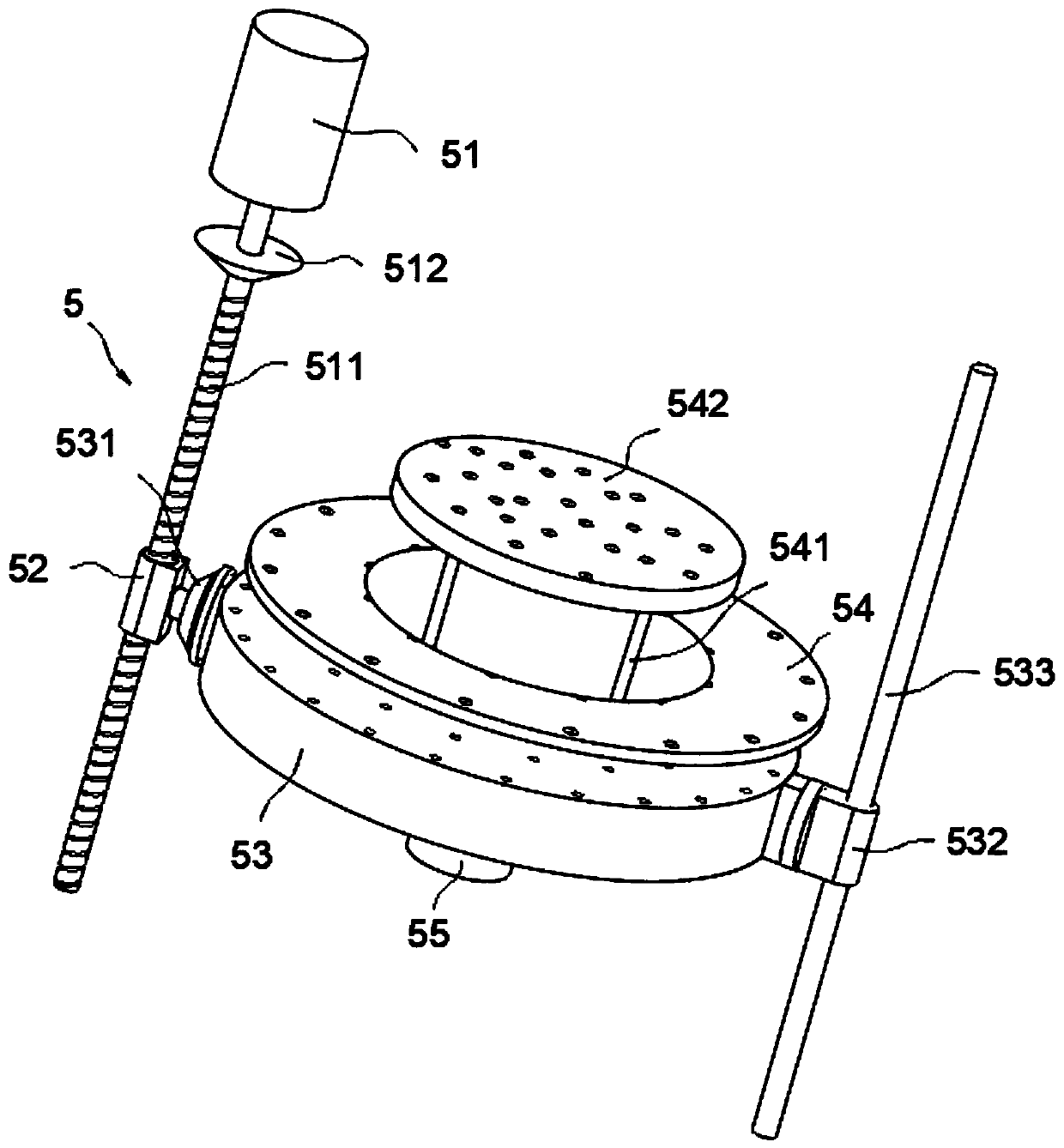

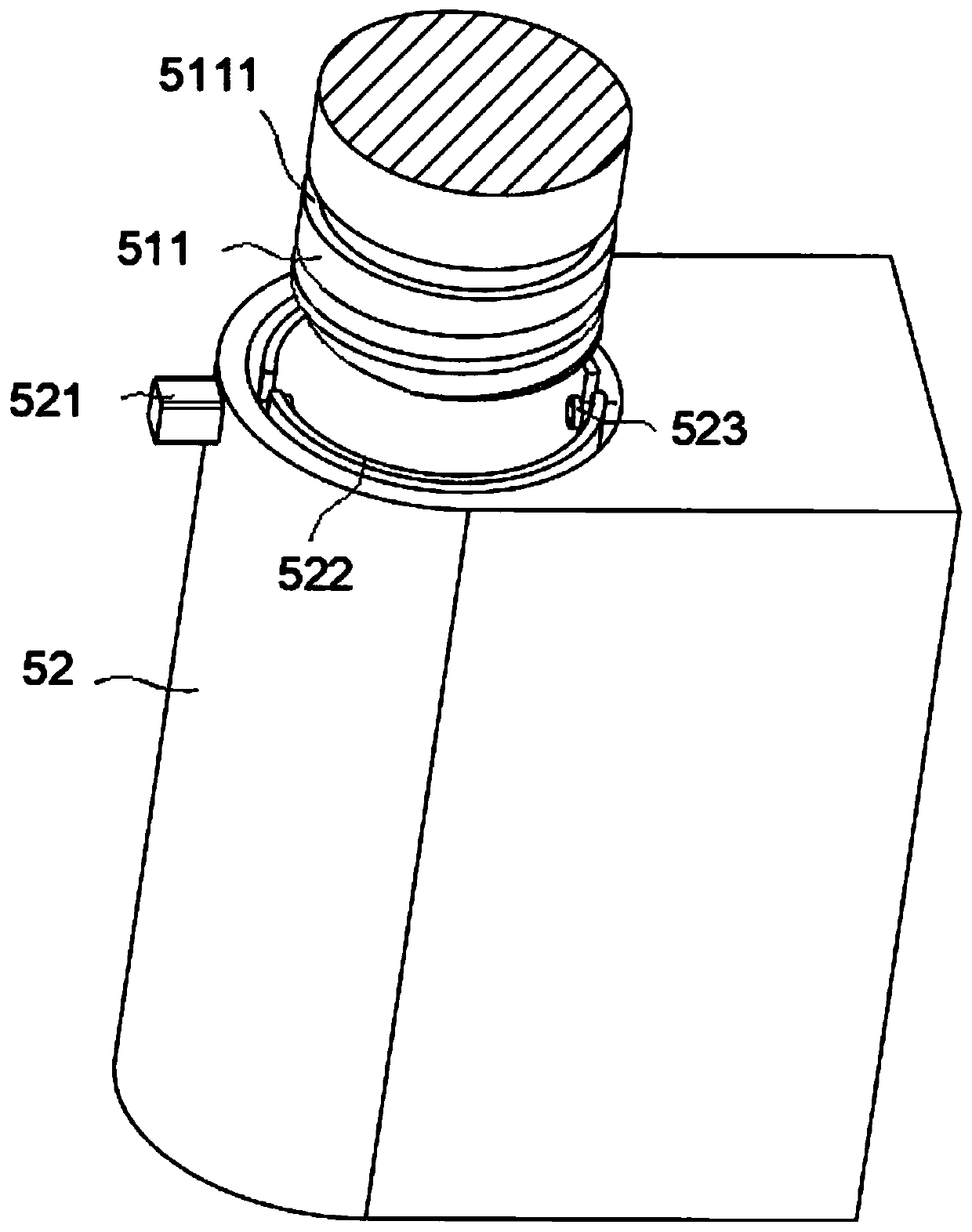

[0035] Embodiment: When using the bait feeding device, the reversing suction assembly 6 is forwardly connected first, so that the bait is passed through the bait feeding pipe 2, passed through the material leveling device 3 and the feeding amount is accurately grasped; then start to catch the bait The shrimp device 4 drives the shrimps downwards, drives the lobsters to the bottom of the housing 43, and then drives the bait recovery device 6 upwards, while using vibration to sieve the fine silt excrement into the silt storage body 53, and is received into the silt In the storage body, the separation of bait and silt and feces is realized; when the silt storage body 53 reaches the highest point, the housing 43 is turned downwards to realize the secondary throwing of the bait, and the silt storage body 53 can be turned over and put into the container again. The feeding area is fed by the lobster again, so that the uneaten bait can be reused to improve the utilization rate of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com