Impeller of oxygen-enriching machine

A technology of aerator and impeller, applied in fish farming, application, animal husbandry, etc., can solve the problems of limited air, short contact time between water and air, poor oxygenation effect, etc., to improve fluidity, reduce resistance, the effect of reducing drive power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

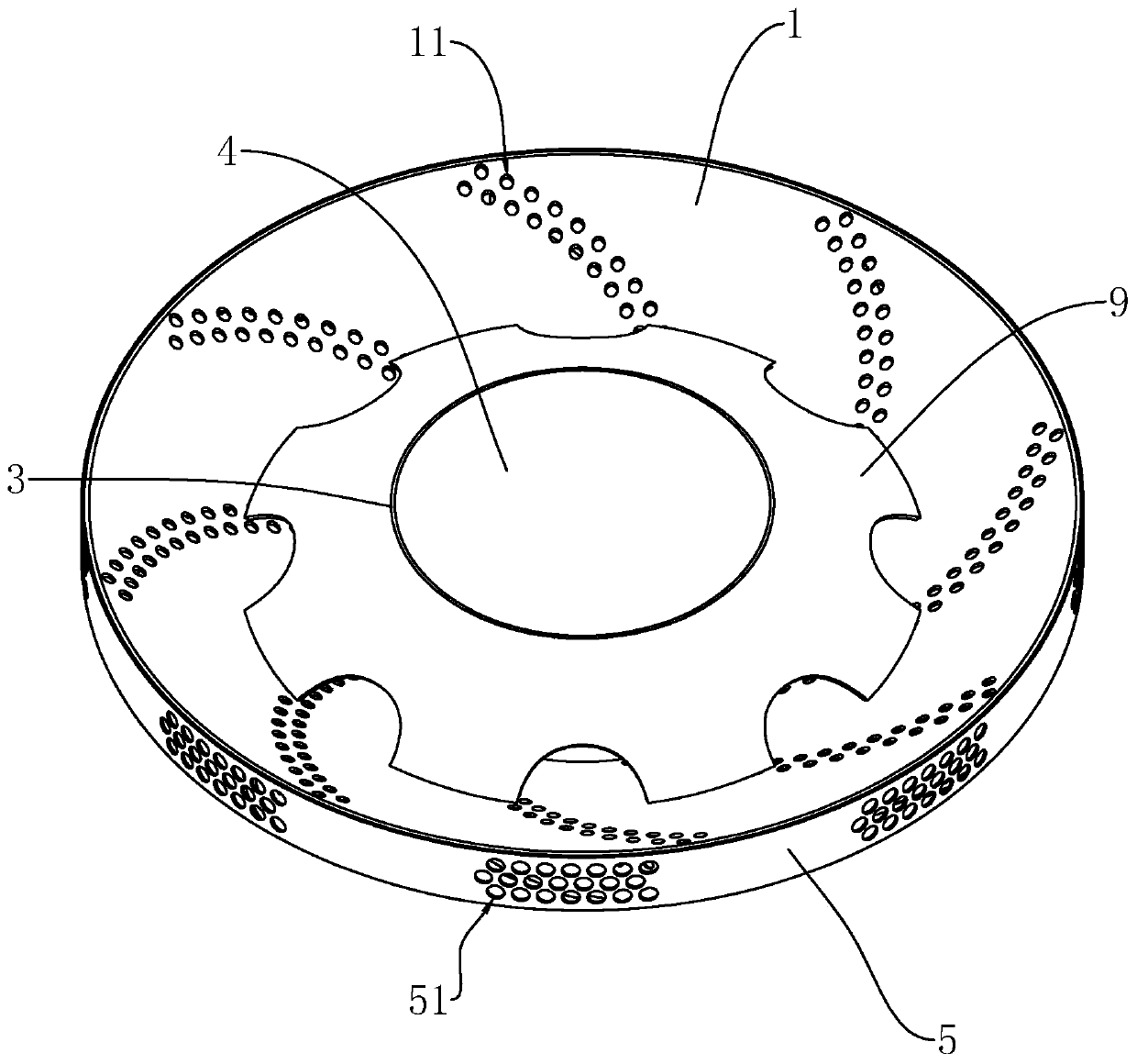

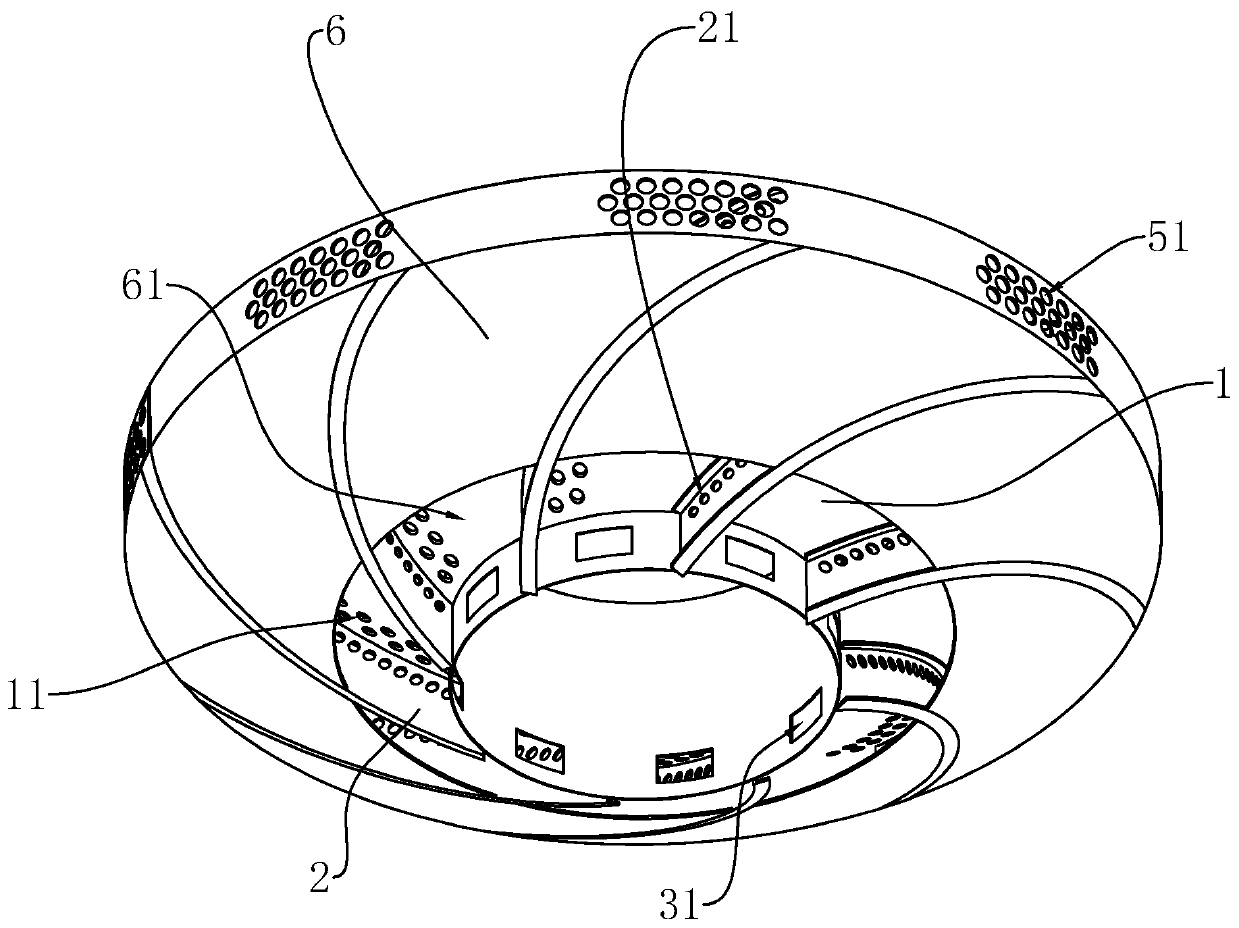

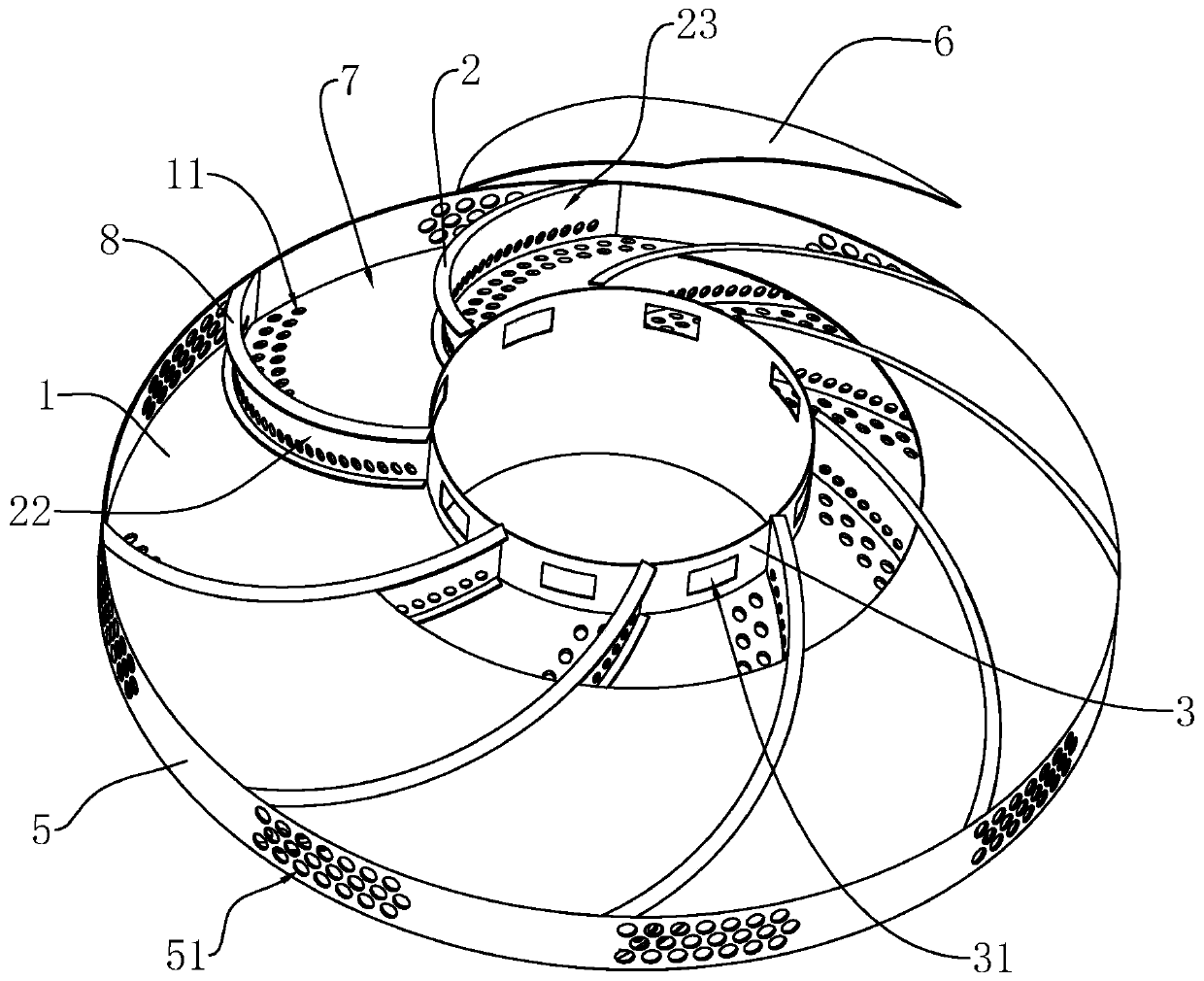

[0039] Embodiment 1: a kind of aerator impeller disclosed by the present invention, see figure 1 , comprising a roulette 1 and a straight cylinder 3 . The roulette 1 is a tapered cylinder, the straight cylinder 3 is arranged coaxially with the roulette 1, one end of the straight cylinder 3 passes through the small end of the roulette 1, and the circumferential outer wall of the straight cylinder 3 is welded to the inner diameter of the small end of the roulette 1. The other end of the straight cylinder 3 is located in the large end of the wheel disc 1, and a connecting ring 9 is provided on the circumferential outer wall of the large end of the straight cylinder 3, and the inner ring side wall of the connecting ring 9 is welded on the circumferential outer wall of the straight cylinder 3, The outer ring edge of the connecting ring 9 is welded and fixed to the side wall of the wheel disc 1 . A mounting seat 4 is fixed on the circumferential inner wall of the straight cylinder ...

Embodiment 2

[0044] Example 2: see Figure 5 The difference between this embodiment and Embodiment 1 is that the end of the plate 6 away from the annular retaining ring 5 continues to extend along the length direction of the blade 2 and is welded to the circumferential outer wall of the straight cylinder 3 . There are multiple water inlets 61 on a plate 6, and the multiple water inlets 61 on the same plate 6 are all close to the adjacent blades 2 facing the corresponding mixing chamber 7 with the negative pressure surface 23, and the multiple water inlets 61 on the same plate 6 It is arranged along the length direction of the adjacent blade 2. Each water inlet 61 is covered with a guide piece 63, the guide piece 63 is on the side of the cover plate away from the mixing chamber 7, the shape of the guide piece 63 is a triangular cone, one side of the guide piece 63 faces the direction of rotation of the impeller and A water diversion channel communicating with the corresponding water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com