Investment casting core

An investment casting and core technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve problems such as affecting the strength and service life of parts, reducing the processing quality of parts, and insufficient casting of the core metal solution. The effect of processing quality, prolonging the overall service life and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

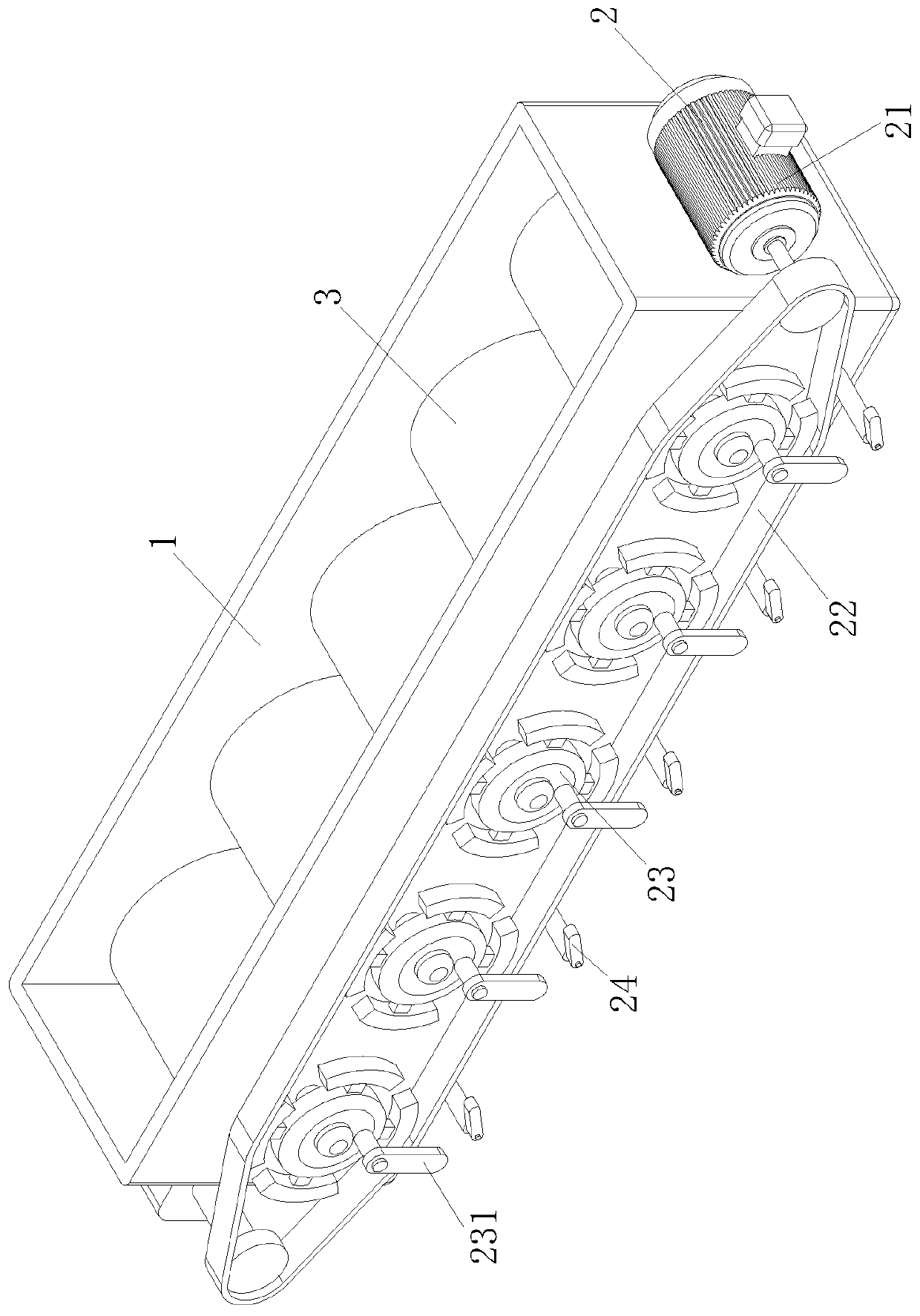

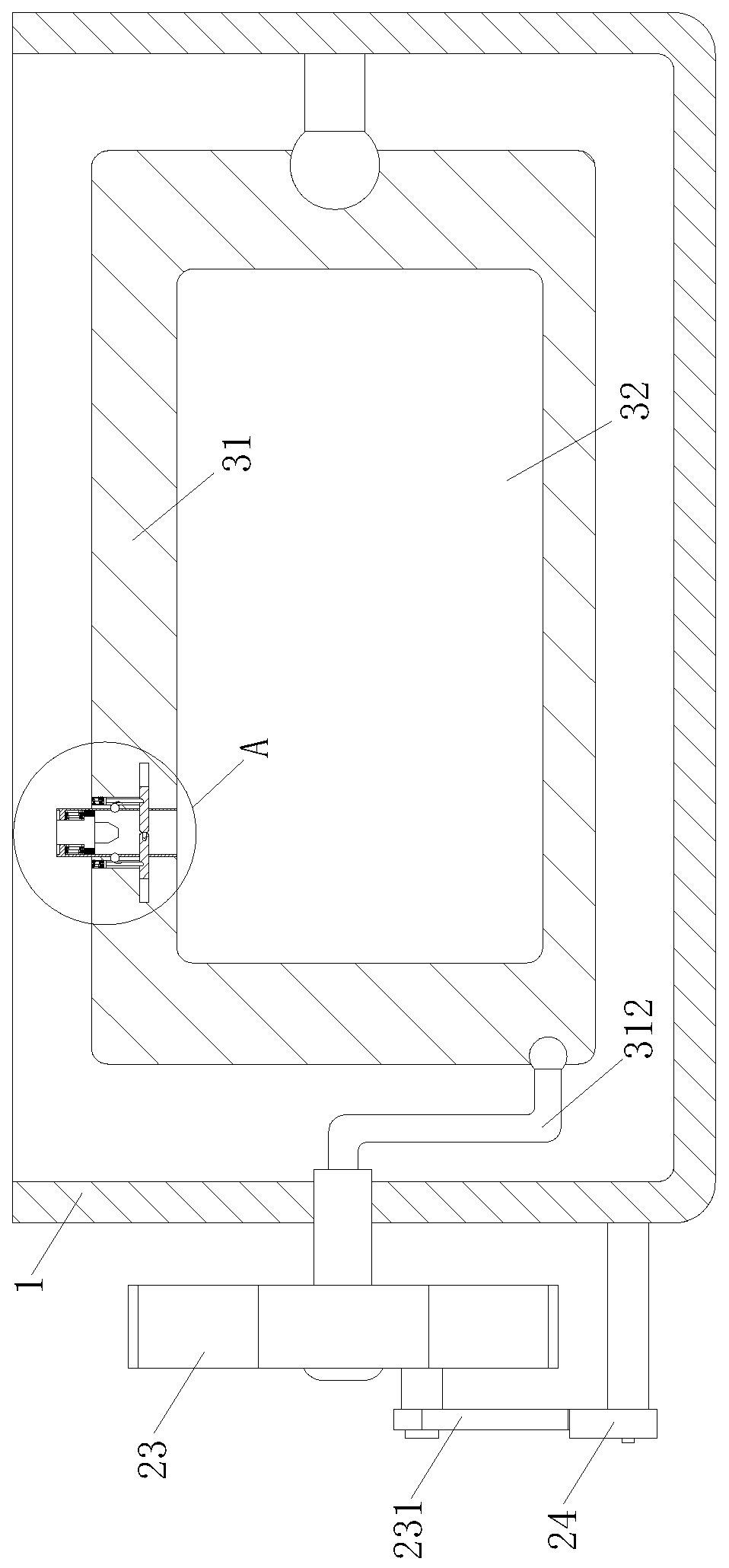

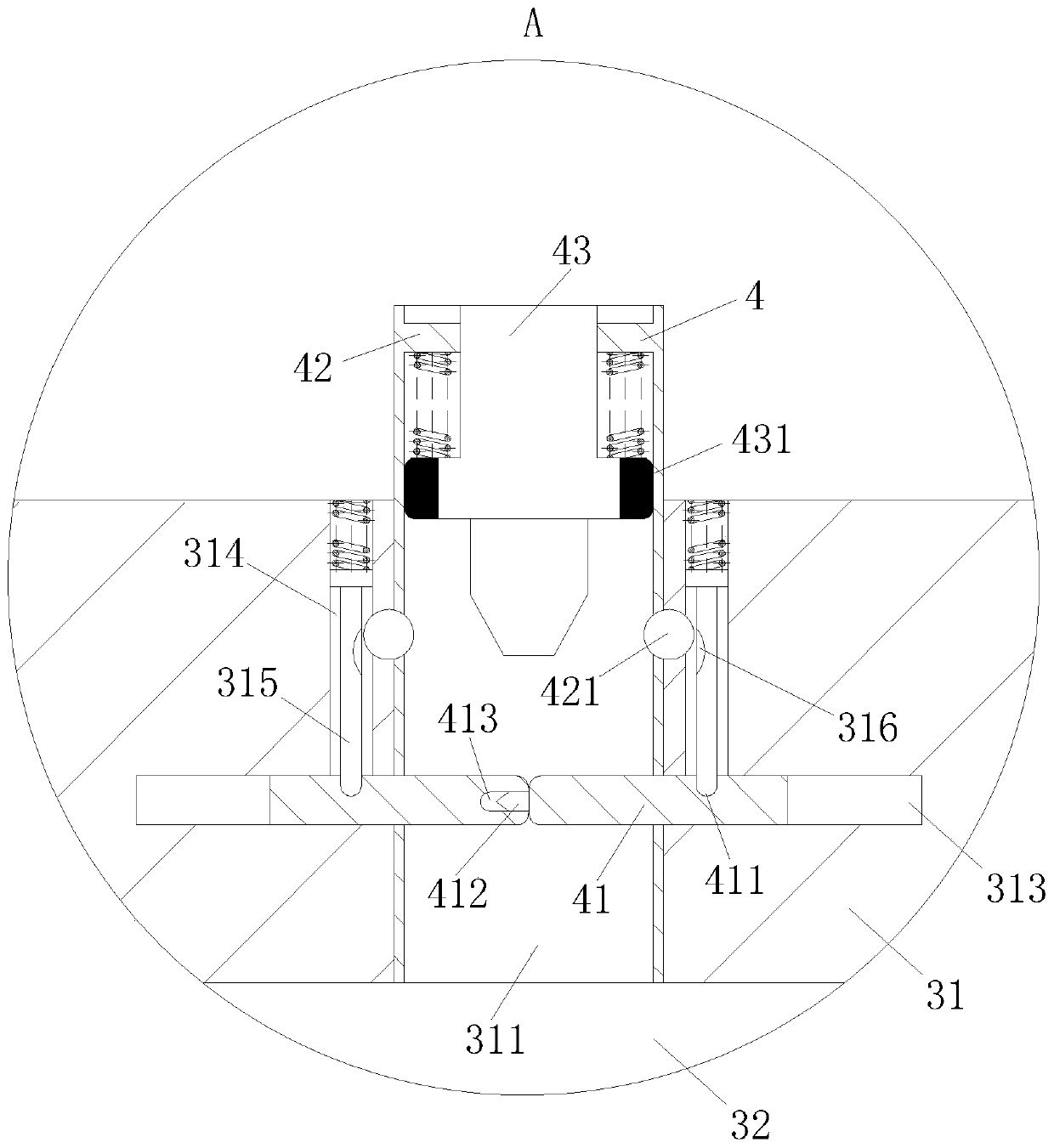

[0024] As an embodiment of the present invention, a cavity 232 is opened in the transmission wheel 23, and an adjustment unit 5 is arranged in the cavity 232; the adjustment unit 5 includes an arc block 51, a connecting rod 52, a The connecting rod 53 and the rotating disk 54; the rotating disk 54 is connected in the cavity 232 in rotation; the blocking rod 231 is slidingly connected on the side wall of the transmission wheel 23, and the end of the blocking rod 231 is connected to the surface of the rotating disk 54 in rotation; the one No. connecting rod 52 is slidably connected on the side wall of cavity 232; said arc block 51 is installed with the end of No. 1 connecting rod 52 located on the outside of transmission wheel 23; 52 is located at the end of the cavity 232, and the other end is rotatably connected to the surface of the turntable 54; through the cooperation of the arc block 51, the first connecting rod 52, the second connecting rod 53 and the turntable 54, the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com