Floating head for drilling and floating drilling device

A drilling device and floating head technology, used in drilling/drilling equipment, positioning devices, transportation and packaging, etc., can solve the problems of floating reamer cutting allowance stuck, small floating amount, insufficient power, etc. Improve drilling efficiency, prevent tool jamming, and improve the effect of floating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

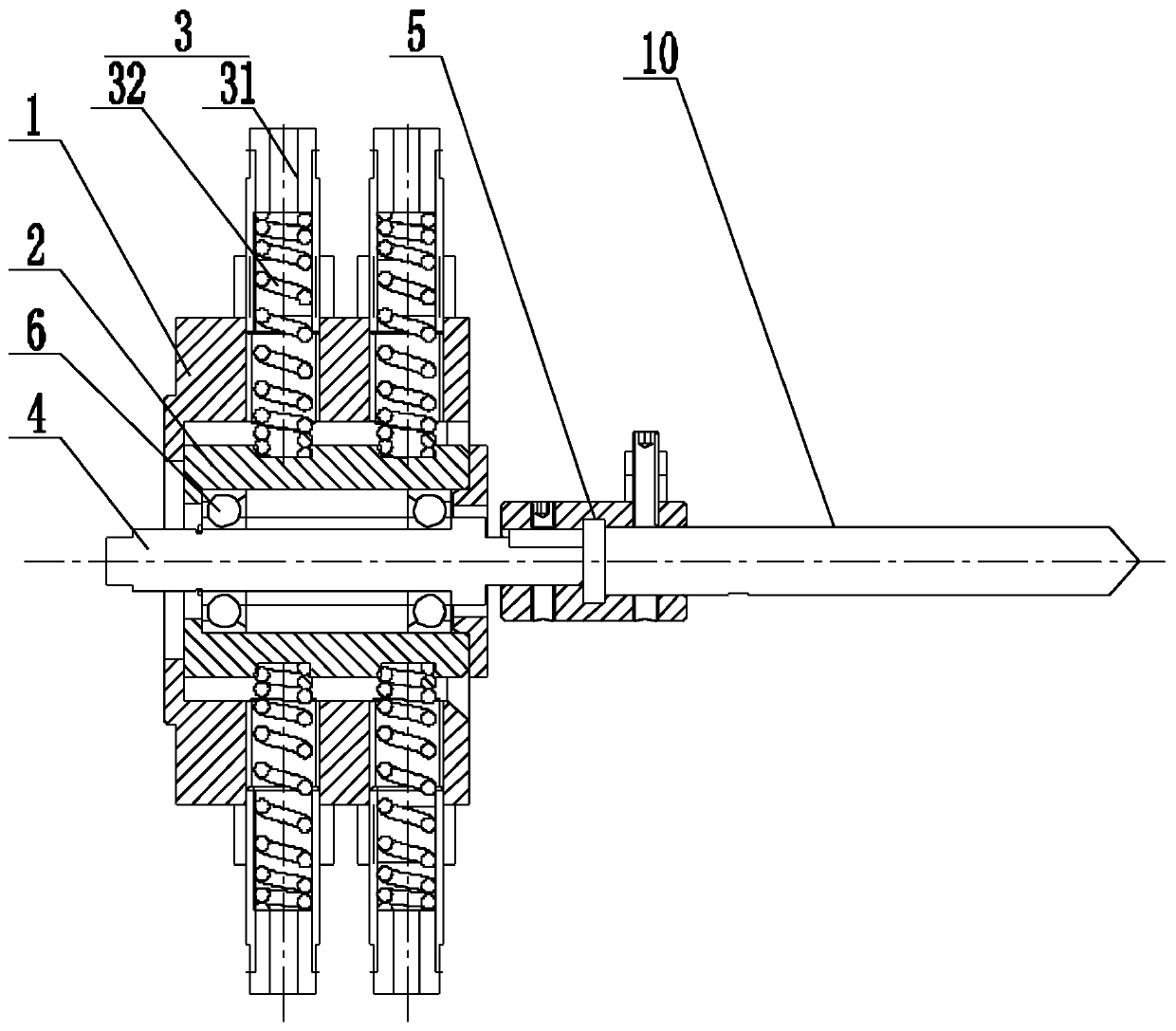

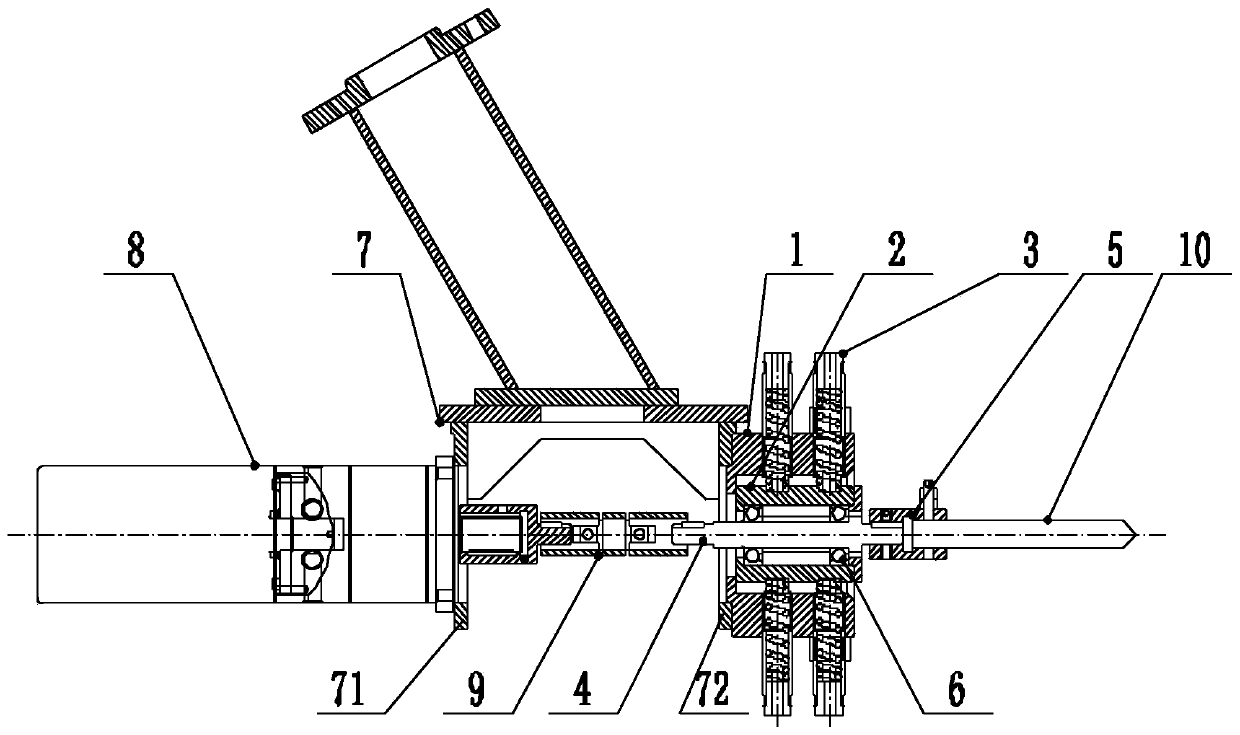

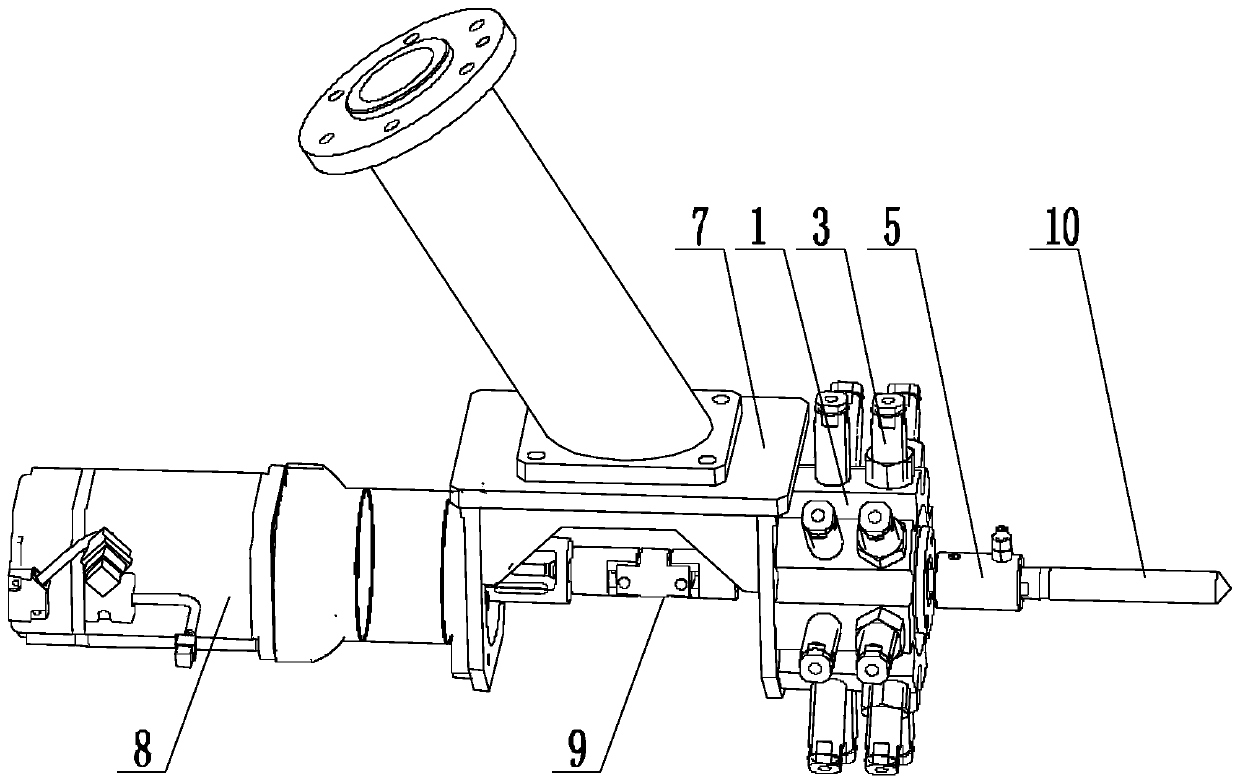

[0024] like Figures 1 to 3 as shown, figure 1 A structural schematic diagram of a floating head for drilling proposed by the present invention, figure 2 It is a structural schematic diagram of a floating drilling device proposed by the present invention, image 3 It is a schematic diagram of a three-dimensional structure of a floating drilling device proposed by the present invention.

[0025] refer to figure 1 , a floating head for drilling and a floating drilling device proposed by the present invention, comprising: an outer casing 1, a bearing seat 2, a floating connector 3, and a connecting shaft 4;

[0026] The middle part of the bearing seat 2 is provided with an installation through cavity, and a rotating bearing 6 is arranged inside the installation through cavity, and the connecting shaft 4 is arranged through the installation through cavity and is rotatably installed on the bearing seat 2 through the rotating bearing 6, and one end of the connecting shaft 4 Equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com