Device and method for preparing high-purity gallium

A high-purity, cooling water pipe technology, applied in the direction of chemical instruments and methods, self-regional melting method, single crystal growth, etc., can solve the problems of low purification efficiency and unstable interface, so as to improve the purification efficiency, ensure the purity and avoid shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

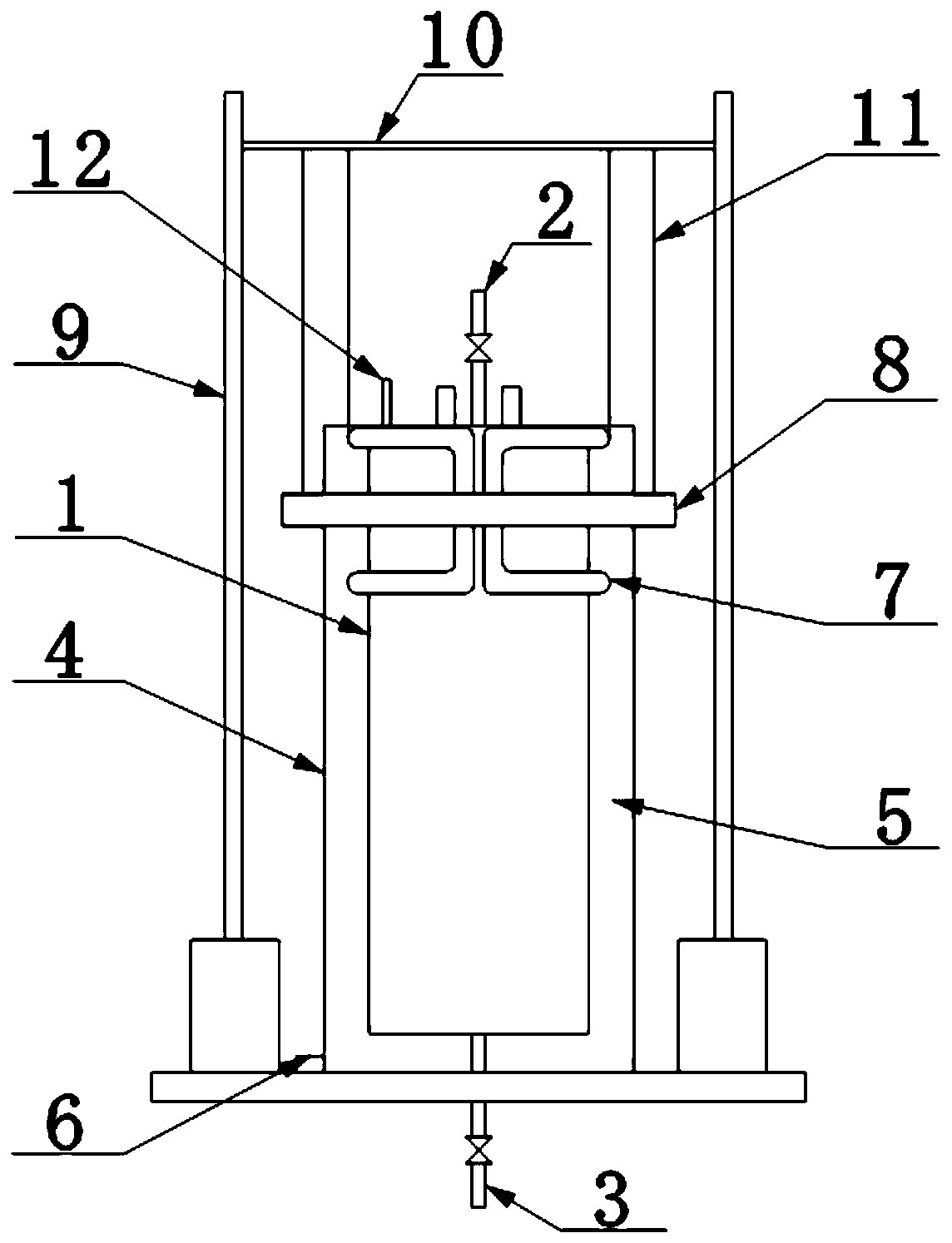

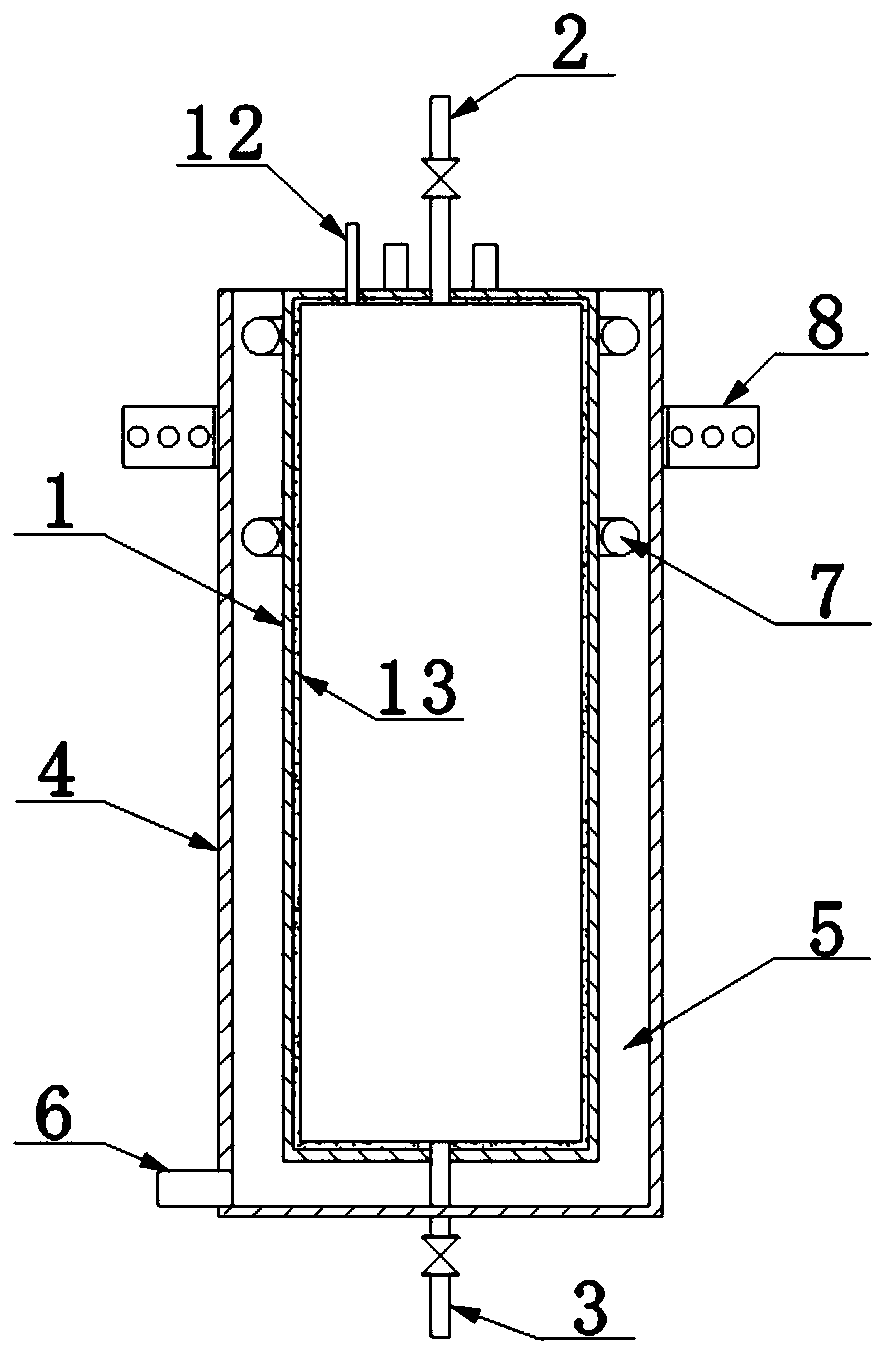

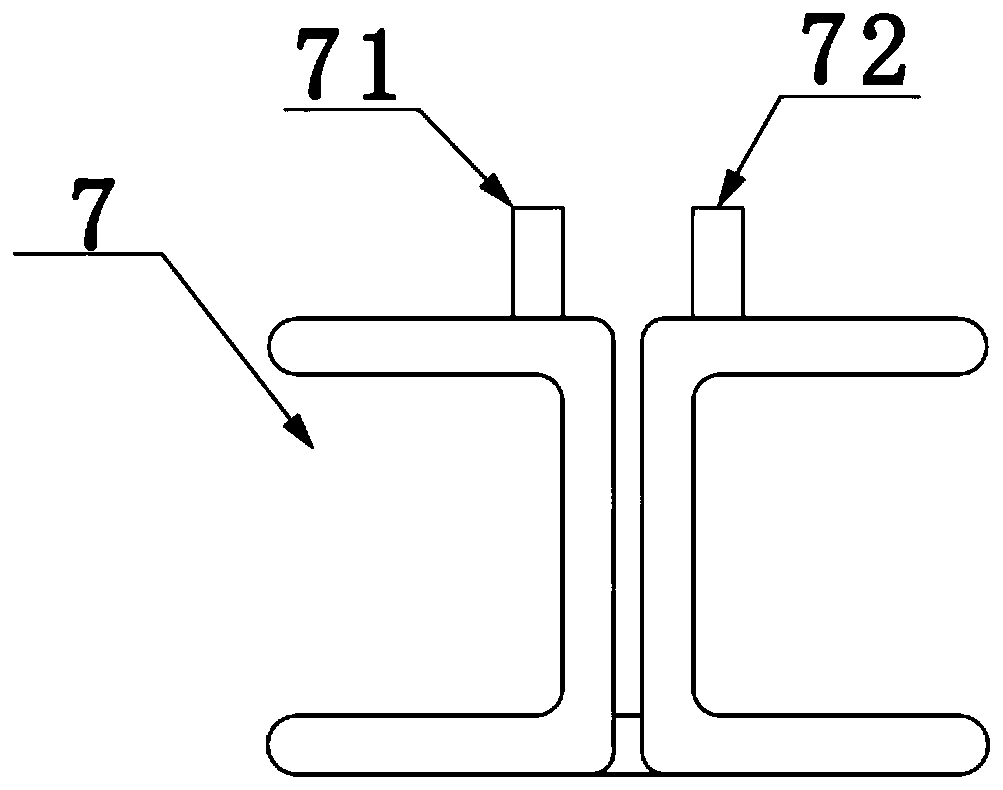

[0035] In the embodiment of the present invention, such as Figure 1~2 As shown, a device for preparing high-purity gallium is provided, and the device in the present invention includes a melting cylinder 1 and an auxiliary melting system. Such as figure 2 As shown, the smelting cylinder 1 is in the shape of a cylinder as a whole, and its two ends are sealed. In order to ensure the stable and efficient smelting, the smelting cylinder 1 is preferably made of a hard material with good heat conduction, such as stainless steel. However, in order to be able to Visually observe the melting condition in the melting cylinder. The melting cylinder is preferably made of transparent materials such as quartz or glass. And the height of the melting cylinder 1 is set to 1500mm, the thickness is set to 2mm, and the inner diameter is set to 50mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com