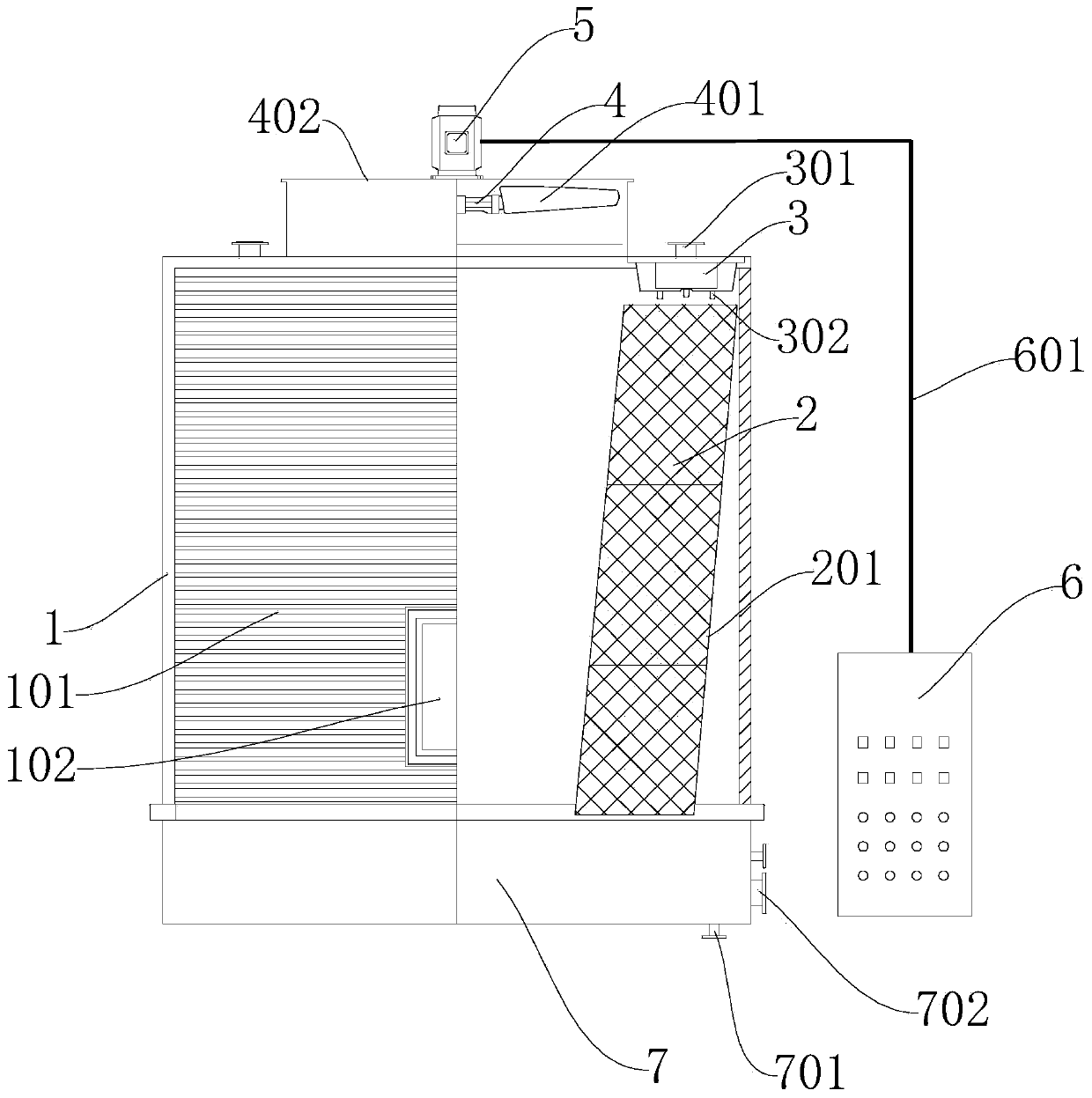

Smart frequency conversion control cooling tower equipped with permanent magnet direct drive motor

A permanent magnet direct drive, frequency conversion control technology, applied in water shower coolers, direct contact heat exchangers, sounding equipment, etc. problems such as low efficiency, to achieve high cooling capacity, reduce energy consumption, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The protective skin 101 is a folded plate structure, the rubber seal is used between the viewing window 102 and the protective skin 101, the packing support 201 is in the shape of an annular cone barrel, the packing support 201 forms an angle of 5° with the wall of the tower body 1, and the water inlet pipe 301 Formed integrally with the water distribution device 3, the water distribution nozzle 302 of the water distribution device 3 is located above the top of the filler bracket 201, the permanent magnet direct drive motor 5 is a high torque direct drive motor, and can realize speed adjustment and torque adjustment with the intelligent frequency conversion control cabinet 6 , and by setting the temperature monitoring function on the intelligent frequency conversion control cabinet 6, the device can automatically adjust the speed of the permanent magnet direct drive motor 5 at night or when the ambient temperature is low, reducing the energy consumption when the speed dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com