Plant extract-soaked nano-microporous zinc oxide solid and preparation method thereof

A plant extract and nano-microporous technology, which is applied to the field of plant extract impregnating nano-microporous zinc oxide solid matter and its preparation, can solve the complex preparation process of Chinese herbal anti-oxidants, weak persistence of antioxidant capacity, and effective effect. Short cycle and other problems, to achieve the effect of improving the effective antioxidant time, simple preparation process and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

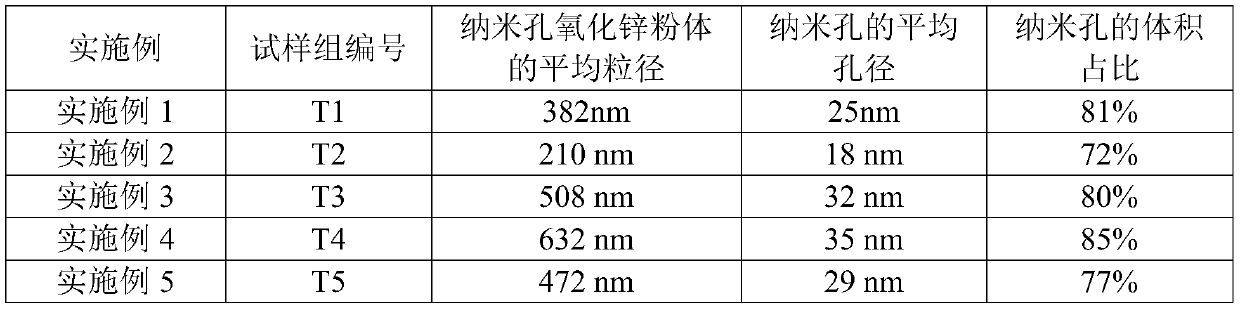

Embodiment 1

[0031] Preparation of plant extract impregnated nano-microporous zinc oxide solid:

[0032] 1. Preparation of nanoporous zinc oxide

[0033] 1) Preparation of wet gel precursor

[0034] According to the ratio of parts by weight, 100 parts by weight of 0.015mol / L zinc acetate solution is added to 80 parts by weight of absolute ethanol, stir well, add 250 parts by weight of 0.1mol / L sodium hydroxide solution, 1.5 parts by weight 0.1 mol / L cetyltrimethylammonium bromide and 1.5 parts by weight of polyethylene glycol, heated and stirred in a water bath at 55°C for 30 minutes, cooled to room temperature and allowed to stand for 120 minutes to obtain a wet gel precursor;

[0035] 2) Purification of wet gel precursor

[0036] The wet gel precursor is subjected to the first purification treatment in a constant temperature sealed box at 45°C, and the solution is replaced with absolute ethanol every 25 minutes, and the first purification time is 150 minutes;

[0037] The wet gel prec...

Embodiment 2

[0048] Preparation of plant extract impregnated nano-microporous zinc oxide solid:

[0049] 1. Preparation of nanoporous zinc oxide

[0050] 1) Preparation of wet gel precursor

[0051] According to the ratio of parts by weight, 100 parts by weight of 0.015mol / L zinc acetate solution is added to 80 parts by weight of absolute ethanol, stir well, add 250 parts by weight of 0.1mol / L sodium hydroxide solution, 1.5 parts by weight 0.1 mol / L cetyltrimethylammonium bromide and 1.5 parts by weight of polyethylene glycol, heated and stirred in a water bath at 55°C for 30 minutes, cooled to room temperature and allowed to stand for 120 minutes to obtain a wet gel precursor;

[0052] 2) Purification of wet gel precursor

[0053] The wet gel precursor is subjected to the first purification treatment in a constant temperature sealed box at 45°C, and the solution is replaced with absolute ethanol every 25 minutes, and the first purification time is 150 minutes;

[0054] The wet gel precur...

Embodiment 3

[0065] Preparation of plant extract impregnated nano-microporous zinc oxide solid:

[0066] 1. Preparation of nanoporous zinc oxide

[0067] 1) Preparation of wet gel precursor

[0068] According to the ratio of parts by weight, 100 parts by weight of 0.015mol / L zinc acetate solution is added to 80 parts by weight of absolute ethanol, stir well, add 250 parts by weight of 0.1mol / L sodium hydroxide solution, 1.5 parts by weight 0.1 mol / L cetyltrimethylammonium bromide and 1.5 parts by weight of polyethylene glycol, heated and stirred in a water bath at 55°C for 30 minutes, cooled to room temperature and allowed to stand for 120 minutes to obtain a wet gel precursor;

[0069] 2) Purification of wet gel precursor

[0070] The wet gel precursor is subjected to the first purification treatment in a constant temperature sealed box at 45°C, and the solution is replaced with absolute ethanol every 25 minutes, and the first purification time is 150 minutes;

[0071] The wet gel prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com