Automatic collecting device for combustion waste gas generation area and provided with swing rod

A technology for automatic collection of combustion exhaust gas, applied in auxiliary devices, gas treatment, smoke and dust removal, etc., can solve problems such as unusable, high cost, and difficult to move, and achieve the effects of easy portability, cost saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

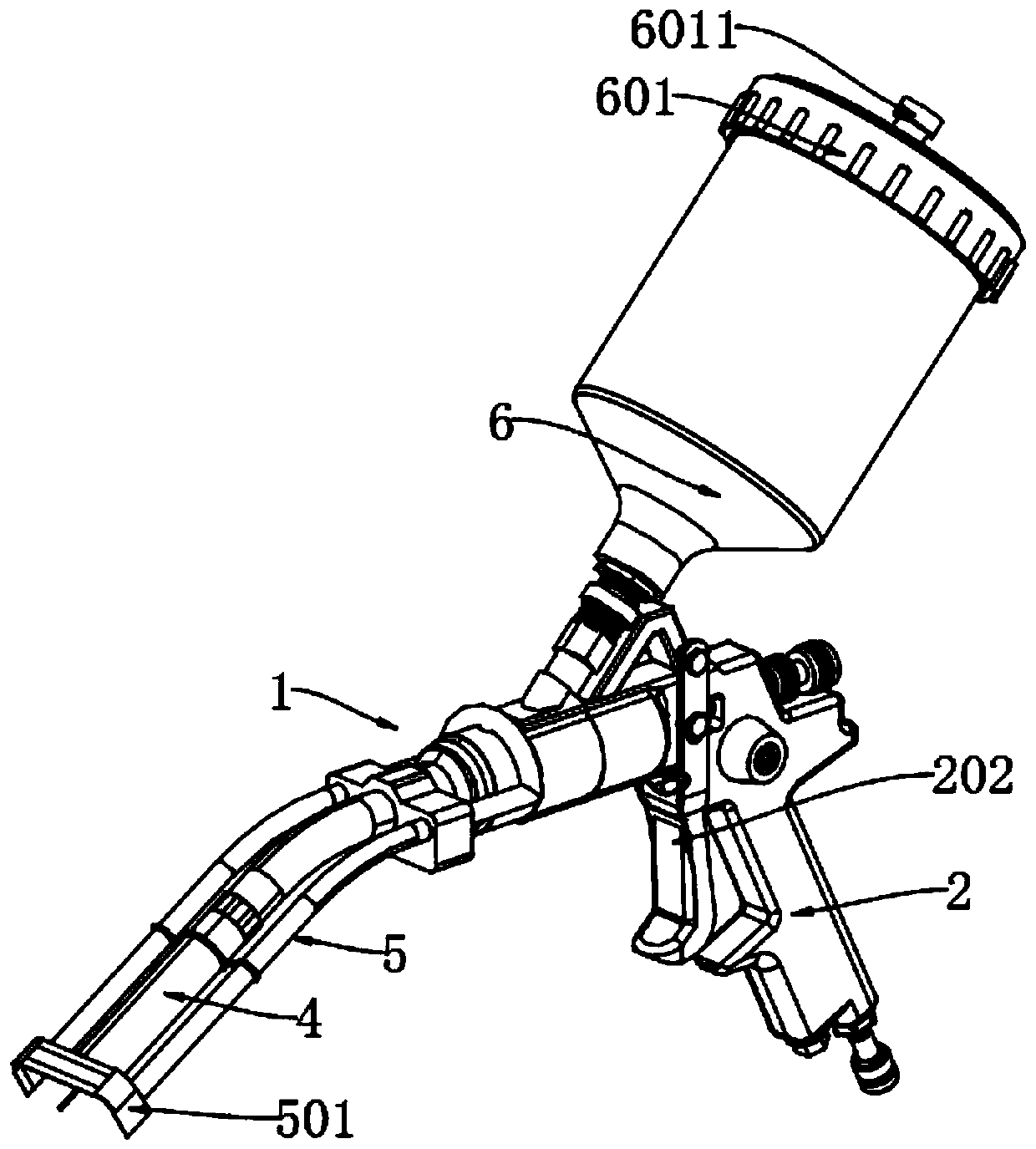

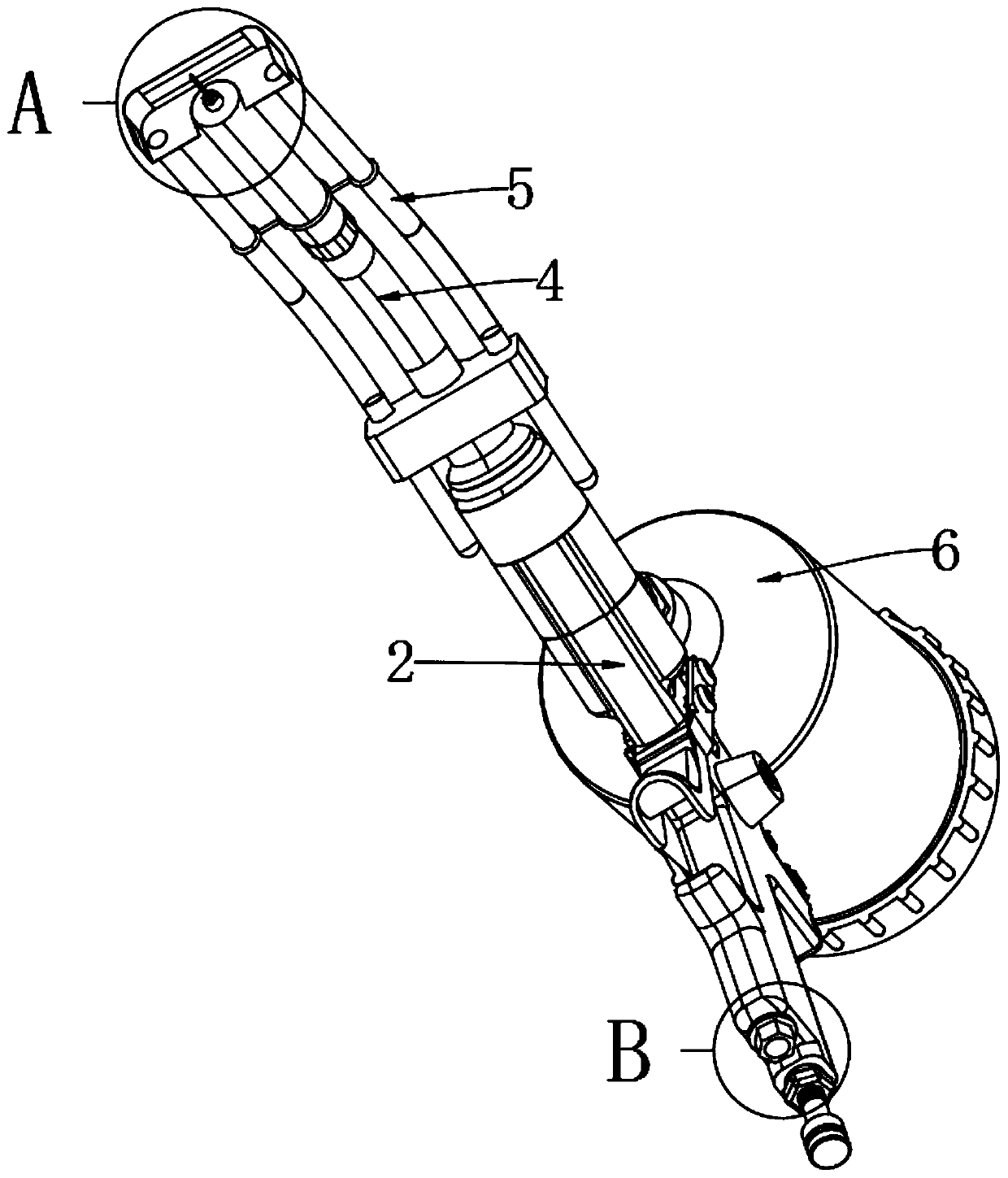

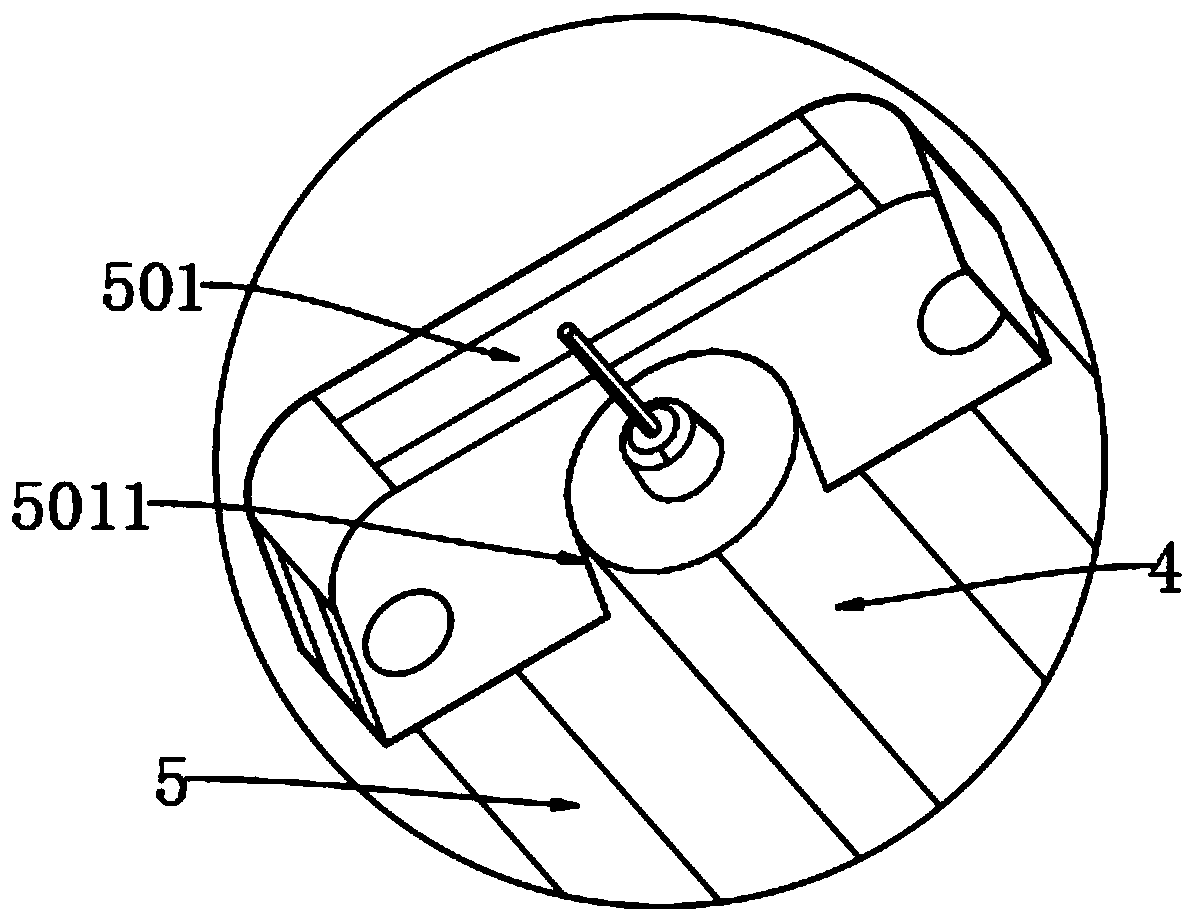

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The present invention provides an automatic collection device for a combustion waste gas generation area equipped with a swing rod, which includes a device main body 1; One end of the bottom side of the handle body 2 is provided with an argon gas inlet connection port 201, and the inner side of the argon gas inlet connection port 201 is provided with an internal thread and is tightly connected with the argon delivery pipe 2036. The front end is provided with a separation chamber 203, and the welding torch tube 4 is connected to the front end of the separation chamber 203, and the waste gas collection pipe 5 is connected to both sides of the welding torch pipe 4 through a clamp ring 502, and the rear end of the waste gas collection pipe 5 passes through Into the separation chamber 203, the lower end of the filter cartridge 6 is connected to the exhaust gas outlet connection port 2035 by thread sealing and contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com