A threaded screwing mechanism for pipe-like fittings oriented to heavy mass and large length-to-diameter ratio

A technology with a large length-to-diameter ratio and pipe fittings, which is applied in the field of similar pipe fittings assembly equipment, can solve the problems of extensive positioning, difficult attitude adjustment, low work efficiency, etc., and achieve the effect of simple structure, low cost and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

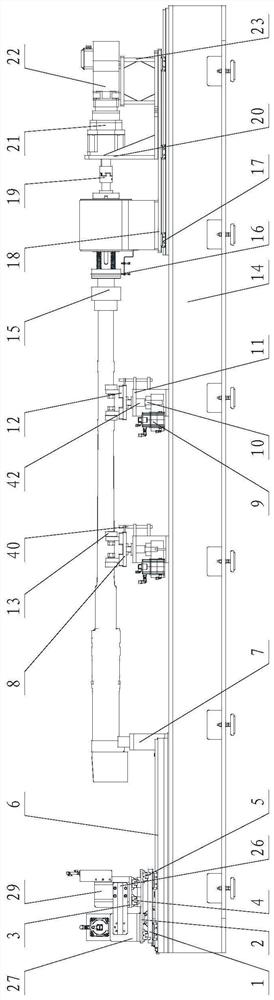

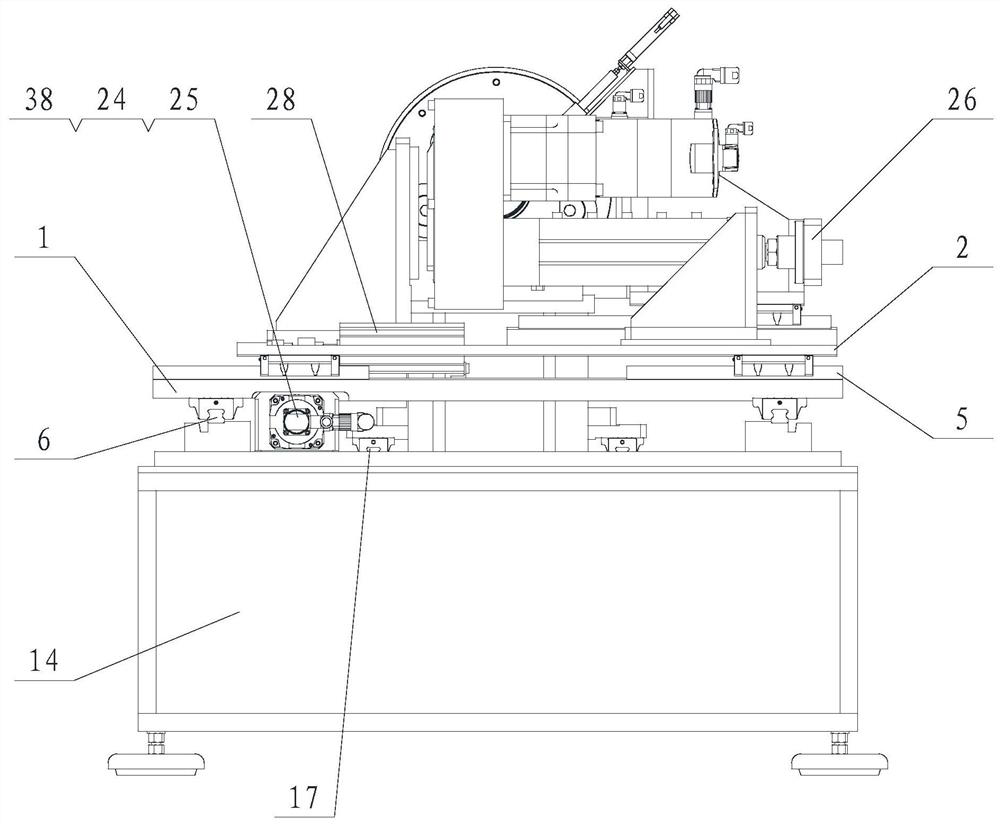

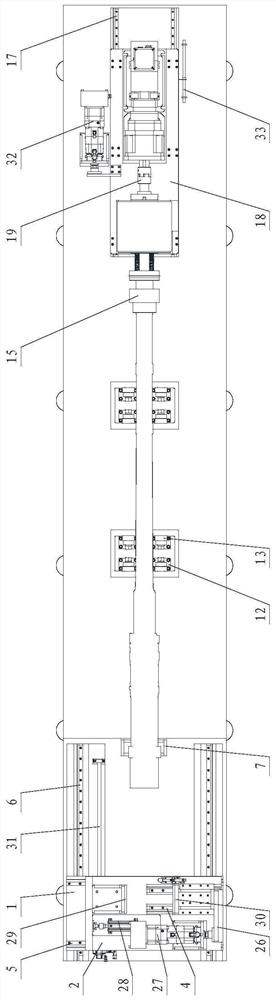

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] like Figure 1~4 As shown, the present invention includes a fuselage 14 and a screwing power application mechanism, an automatic positioning anti-torsion mechanism and an automatic attitude adjustment mechanism respectively installed on the fuselage 14, wherein the screwing power application mechanism and the automatic positioning and anti-torsion mechanism are located on the machine body respectively. At both ends of the body 14, there is at least one attitude automatic adjustment mechanism, which is located between the screwing power application mechanism and the automatic positioning anti-torsion mechanism.

[0032] The screwing power application mechanism comprises a screwing mobile electric cylinder 32, a screwing moving plate 18, a torque applying power unit, a reducer bracket 20, a motor base 23, a torque applying coupling 19, a screwing mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com