Degradable spinning raw material, degradable fiber membrane and degradable protective cover

A technology for degrading fibers and raw materials, applied in protective clothing, protective equipment, fiber chemical characteristics, etc., can solve the problems of secondary virus and bacterial pollution sources of materials, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

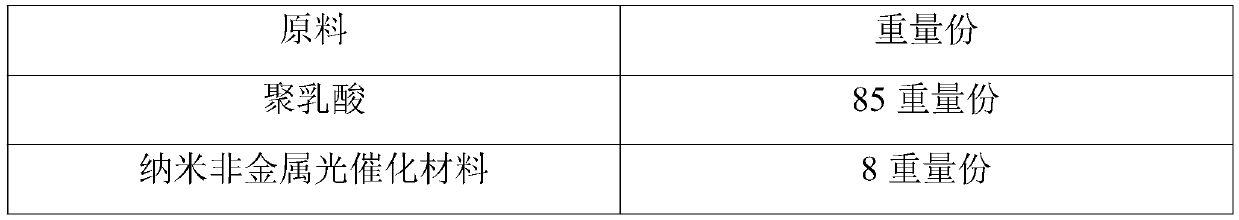

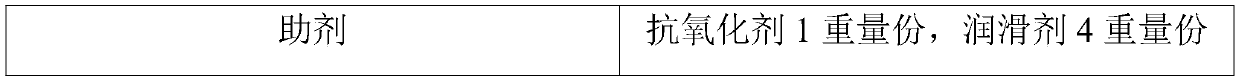

[0046] 1) Take the raw materials by the following parts by weight:

[0047] raw material parts by weight polylactic acid 85 parts by weight Nano-metallic photocatalytic materials 7 parts by weight Auxiliary 1 part by weight of antioxidant, 4 parts by weight of lubricant

[0048] 2) adding the weighed various raw materials into a solvent to form a solution, mixing and melting the solution to form a melt mixture;

[0049] 3) Injecting the melt mixture into an electrospinning device;

[0050] 4) Preparation of degradable fiber membrane by electrospinning equipment;

[0051] 5) Process the degradable fiber film into a degradable protective cover through the protective cover preparation process.

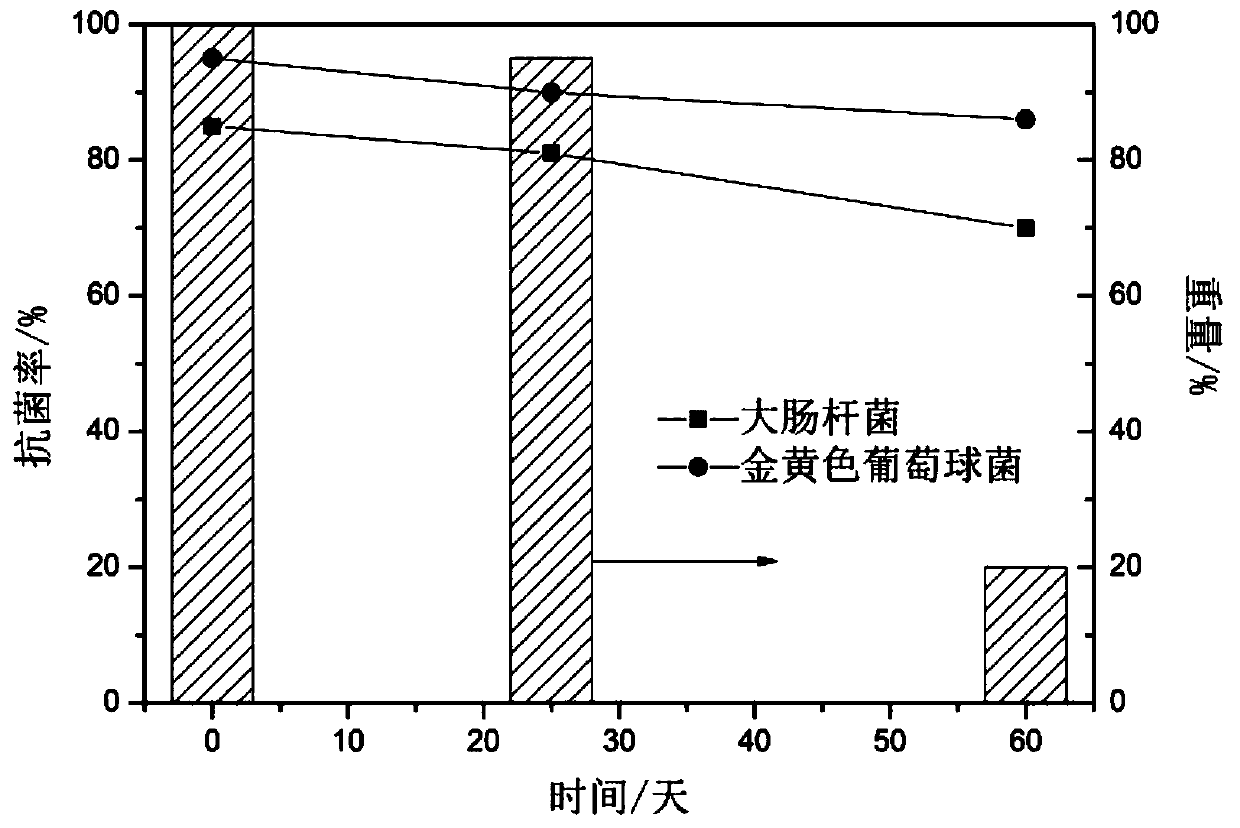

[0052] The degradable protective cover provided by the embodiment of the present invention has excellent anti-virus and bacterial performance, can kill bacteria such as Staphylococcus aureus and Escherichia coli, and can kill viruses such as H1N1, an...

Embodiment 2

[0054] 1) Take the raw materials by the following parts by weight:

[0055] raw material parts by weight PLAG 73 parts by weight Nano-metallic photocatalytic materials 7 parts by weight Auxiliary 2 parts by weight of antioxidant, 2.5 parts by weight of lubricant

[0056] 2) adding the weighed various raw materials into a solvent to form a solution, mixing and melting the solution to form a melt mixture;

[0057] 3) Injecting the melt mixture into an electrospinning device;

[0058] 4) Preparation of degradable fiber membrane by electrospinning equipment;

[0059] 5) Process the degradable fiber film into a degradable protective cover through the protective cover preparation process.

[0060] The degradable protective cover provided by the embodiment of the present invention has excellent anti-virus and bacterial performance, can kill bacteria such as Staphylococcus aureus and Escherichia coli, and can kill viruses such as H1N1, and can ac...

Embodiment 3

[0062] 1) Take the raw materials by the following parts by weight:

[0063] raw material parts by weight polycaprolactone 80 parts by weight Nano-metallic photocatalytic materials 7 parts by weight Auxiliary 2 parts by weight of antioxidant, 2 parts by weight of lubricant

[0064] 2) adding the weighed various raw materials into a solvent to form a solution, mixing and melting the solution to form a melt mixture;

[0065] 3) Injecting the melt mixture into an electrospinning device;

[0066] 4) Preparation of degradable fiber membrane by electrospinning equipment;

[0067] 5) Process the degradable fiber film into a degradable protective cover through the protective cover preparation process.

[0068] The degradable protective cover provided by the embodiment of the present invention has excellent anti-virus and bacterial performance, can kill bacteria such as Staphylococcus aureus and Escherichia coli, and can kill viruses such as H1N1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com