Strengthening and toughening treatment method of steel and iron material

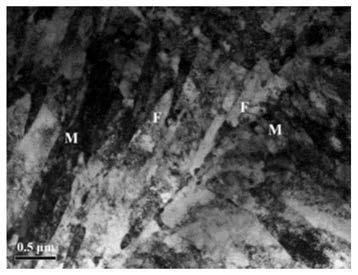

An iron and steel material and processing method technology, applied in the field of material processing technology, can solve the problems of not involving the optimization of ferrite structure, not giving full play to the advantages of sub-temperature quenching process, etc., so as to avoid performance degradation, enhance toughness, and refine iron. The effect of body tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

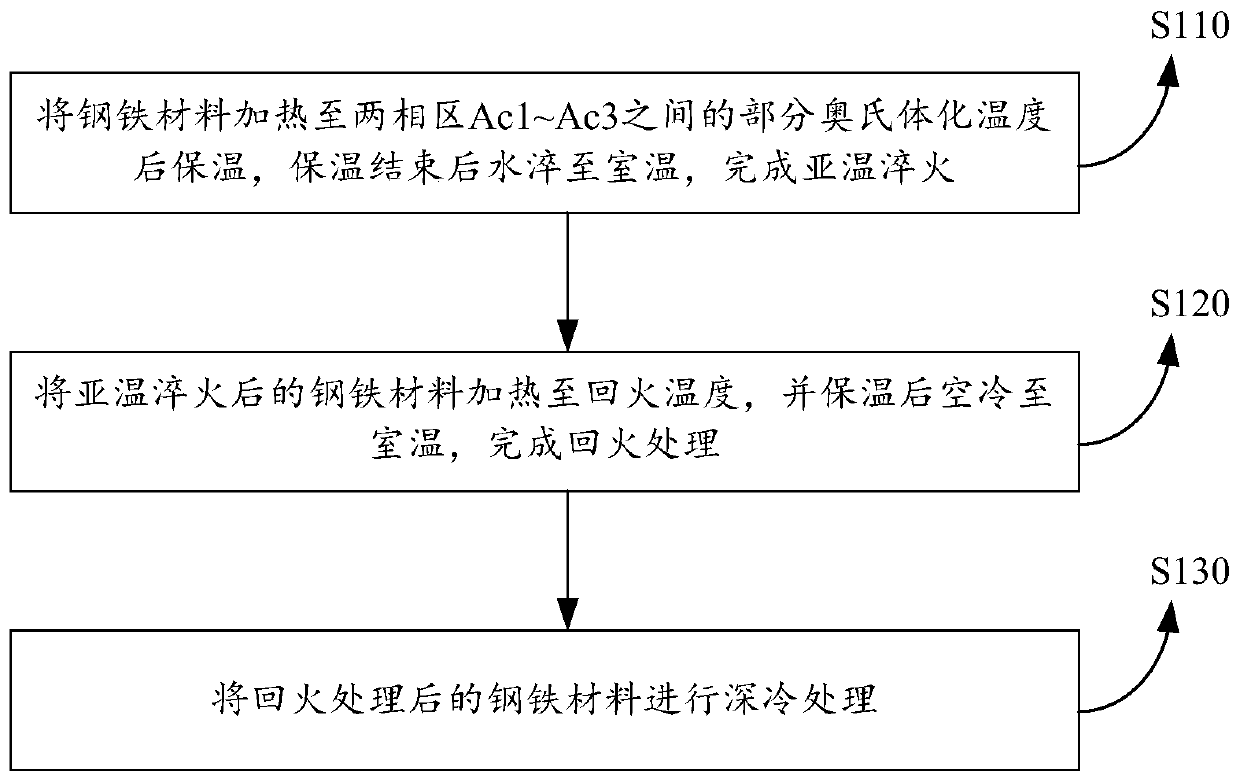

Method used

Image

Examples

Embodiment

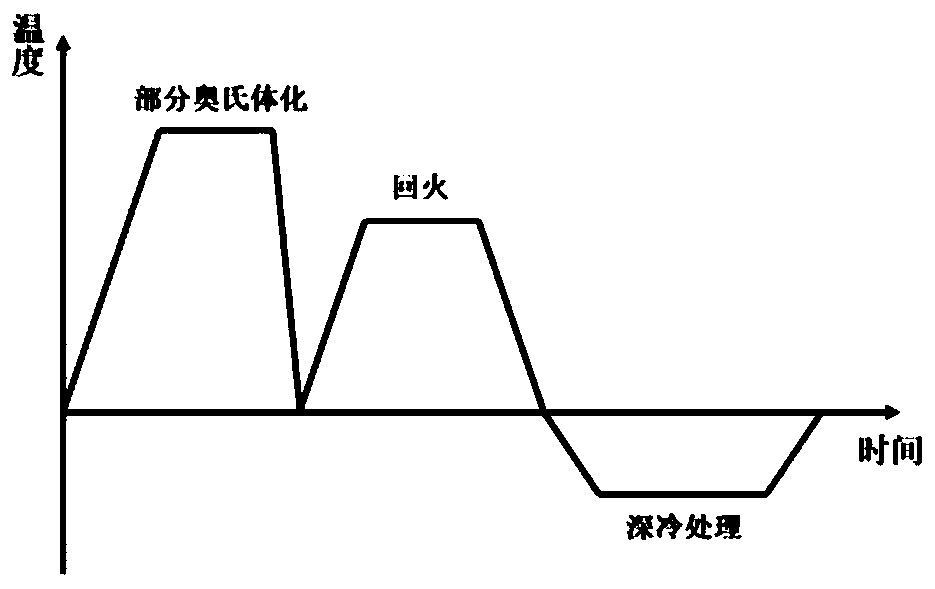

[0047] A kind of alloy structural steel (30CrMnSi) is subjected to tempering-tempering-cryogenic treatment (QTC) for strengthening and toughening. First, it was held at 820°C partial austenitization temperature for 1 h, and then quenched to room temperature. Next, tempering treatment is performed. Finally, the steel material was cooled to -196°C at a cooling rate of 2°C / min, and then raised to room temperature at a heating rate of 2°C / min after being kept for 12 h.

[0048] Table 1 Comparative example and the performance comparison of the embodiment process

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com