Deep multistage dynamic foundation pit precipitation system and precipitation method thereof

A foundation pit and deep-layer technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as difficult processing, increased project cost, and insufficient lap length, etc., to achieve less interference in engineering construction, ensure water-free operation, and reduce pumping The effect of head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

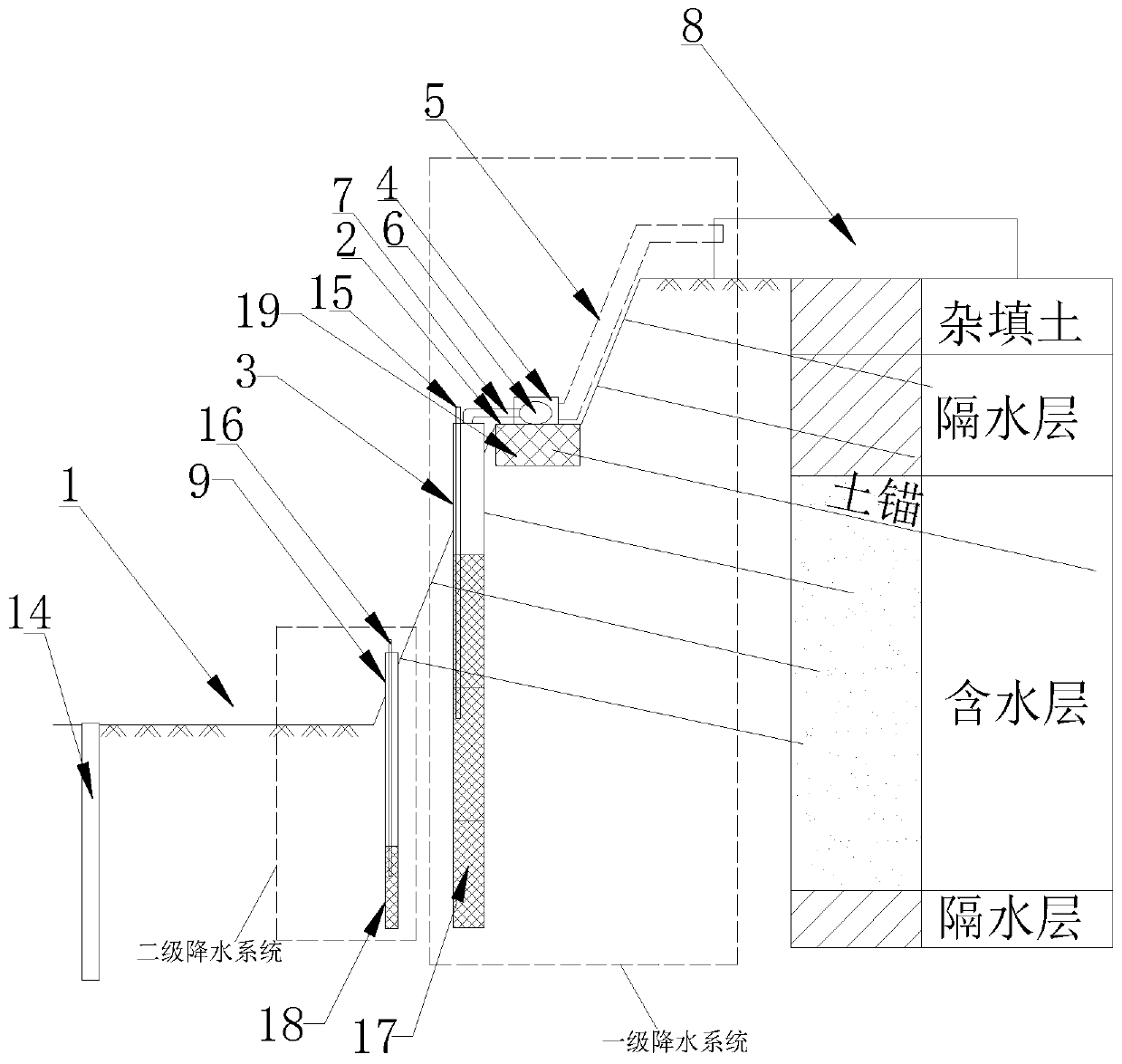

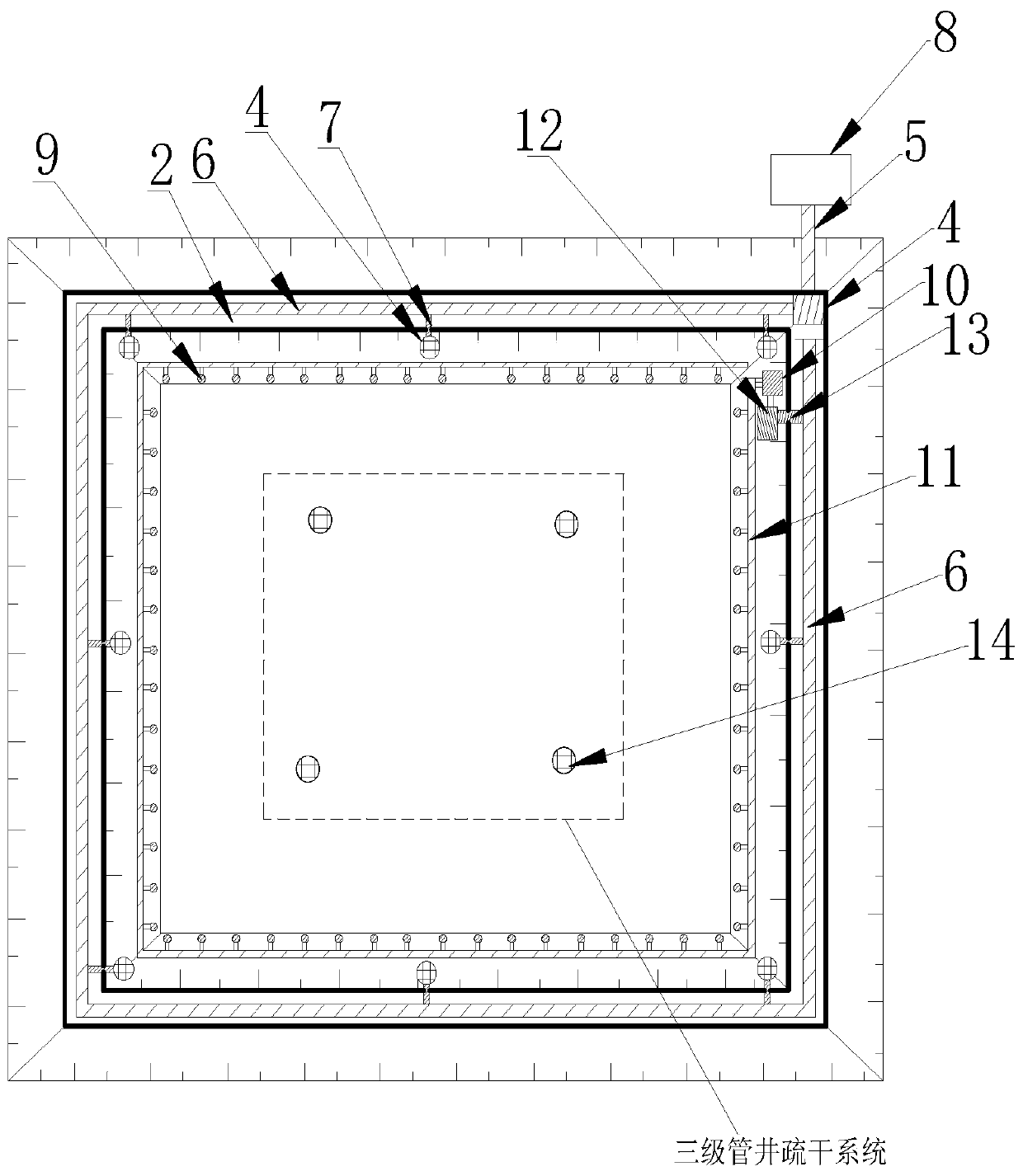

[0030] Embodiment 1: a deep multi-level dynamic foundation pit 1 dewatering system, such as figure 1 and figure 2As shown, it includes a foundation pit 1, the foundation pit 1 is excavated with steps 2, and the foundation pit 1 is provided with a plurality of dewatering pipe wells 3 at equal intervals at the toe of the grading slope. The top surface of the step 2 is provided with a booster pump 4 , a water delivery main pipe 5 and an annular drainage header 6 , and the water delivery header 5 and the annular drainage header 6 are connected to the booster pump 4 . The downpipe well 3 is connected to the annular drainage main pipe 6 through a first branch pipe 7 . The top surface of the foundation pit 1 is provided with a sedimentation tank 8 , and the water outlet end of the water delivery main pipe 5 is connected with the sedimentation tank 8 . The bottom of the foundation pit 1 is provided with a plurality of light well points 9 at equal intervals. A well point pump 10 an...

Embodiment 2

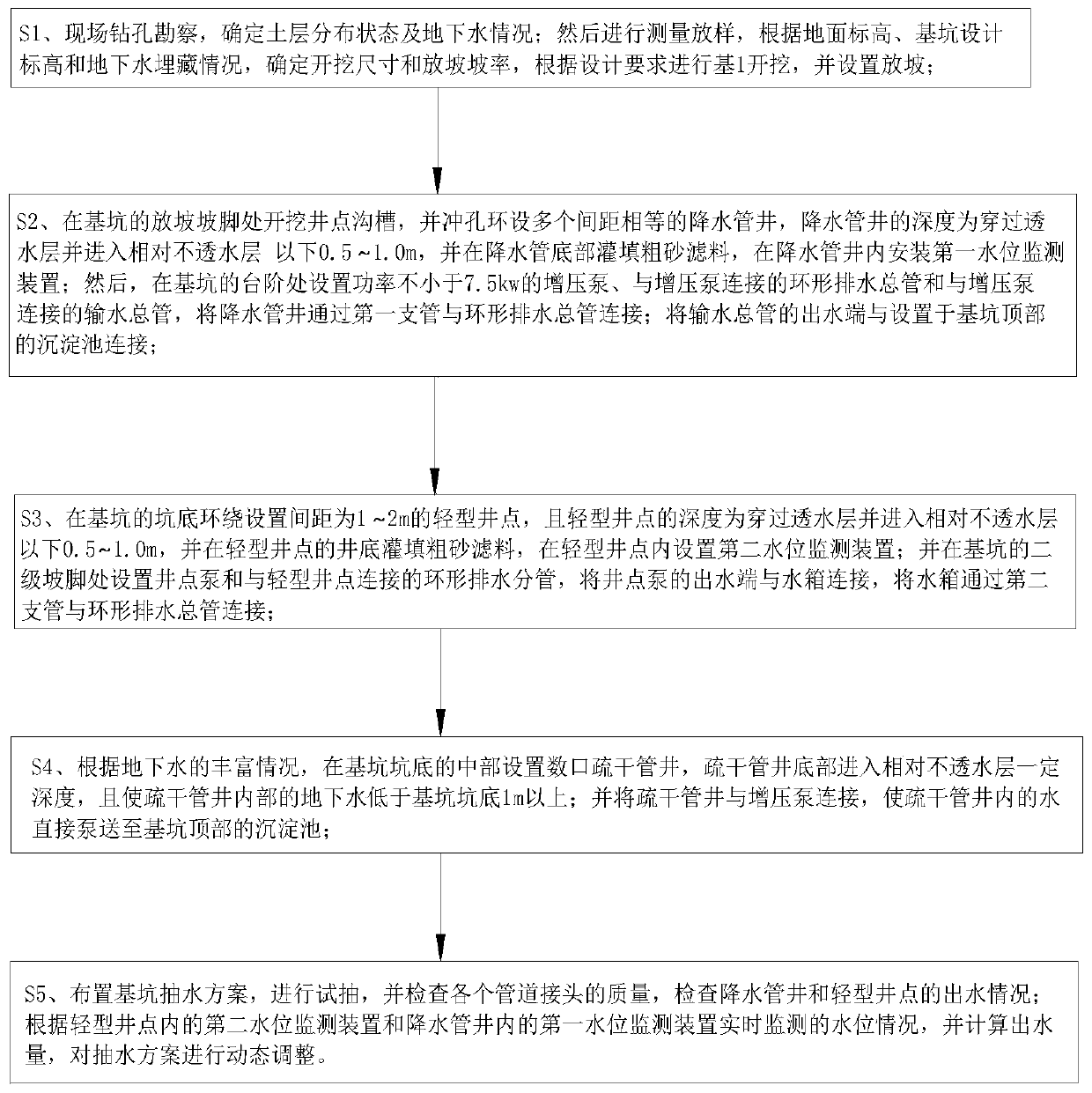

[0042] Embodiment 2: a deep multi-level dynamic foundation pit 1 dewatering method, such as image 3 shown, including the following steps:

[0043] S1. On-site drilling investigation to determine the distribution status of soil layers and groundwater conditions. Then measure and stake out, determine the excavation size and grading slope rate according to the ground elevation, the design elevation of the foundation pit 1 and the groundwater burial situation, excavate the foundation pit 1 according to the design requirements, and set the grading.

[0044] S2. Excavate well point trenches at the foot of the grading slope of foundation pit 1, and set a plurality of dewatering pipe wells 3 with equal spacing around the holes. The depth of dewatering pipe wells 3 is to pass through the permeable layer and enter below the relatively impermeable layer 0.5-1.0m, and the bottom of the downpipe is filled with coarse sand filter material 17, and a first water level monitoring device 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com