Integral dry hanging process of earthenware brick curtain wall

A ceramic brick and integral technology, which is applied in the field of the overall dry-hanging process of the ceramic brick curtain wall, can solve the problems of difficult control of the verticality and horizontality of the ceramic brick curtain wall, the large site occupied by the construction site, and the poor construction quality, so as to save materials and improve the construction quality. The effect of installing quality and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

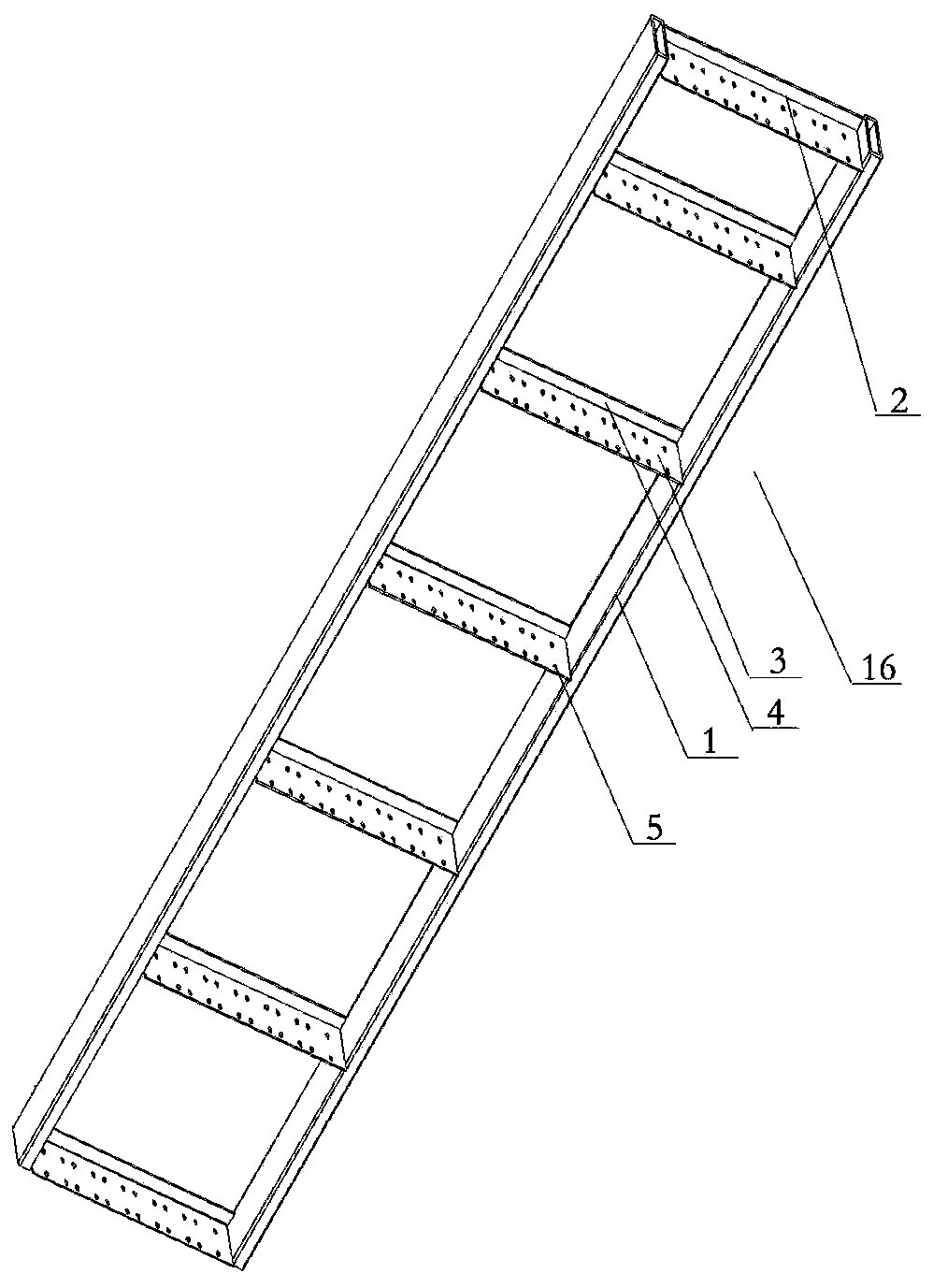

[0056] This embodiment provides a prefabricated unit wall 15, the prefabricated unit wall 15 is completed at the factory stage, including a steel frame 16, ceramic bricks with holes 6 and a positioning structure 17, the width of the entire prefabricated unit wall 15 is 1000 mm, The height is 3900mm.

[0057] Such as figure 1 As shown, the steel frame 16 includes a steel square pipe 1 and an angle steel 2, and the surfaces of the steel square pipe 1 and the angle steel 2 are coated with a zinc protective layer. The length of the cross section of steel square pipe 1 is 100mm, the width is 50mm, and the thickness is 8mm. There are 2 steel square tubes 1 in parallel, 7 angle steel tubes 2, and the angle steel 2 is welded between the two steel square tubes 1. The distance between the upper and lower adjacent angle steel tubes 2 depends on the actual situation, which is about 630mm.

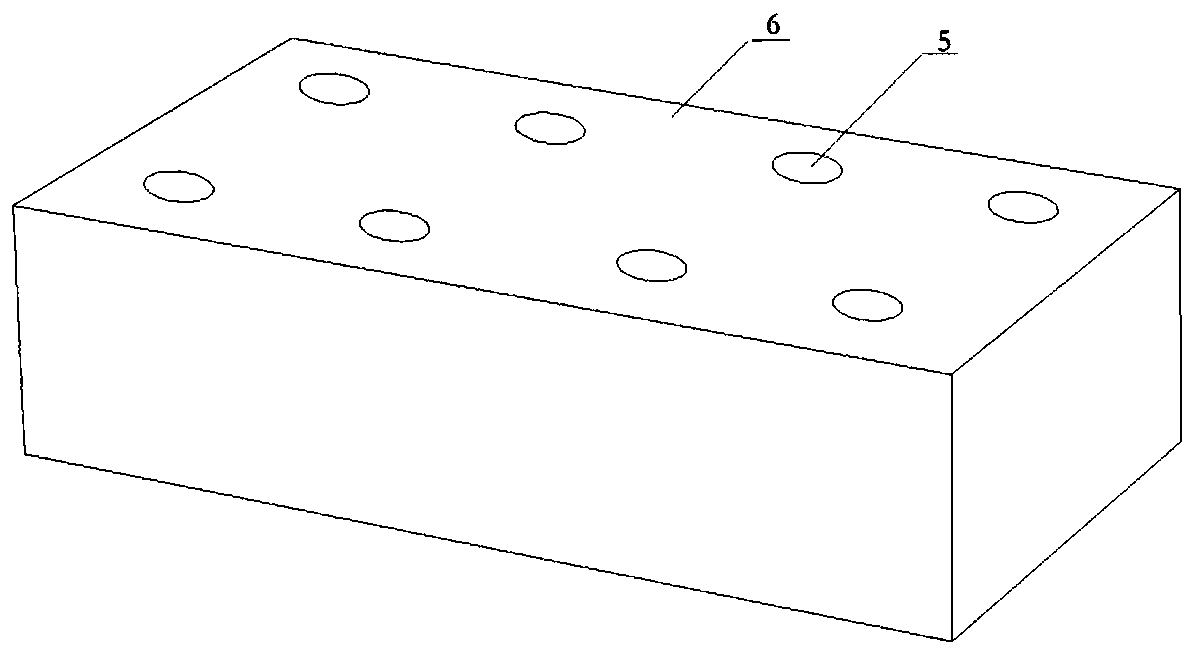

[0058] Such as figure 2 As shown, the pottery brick with holes 6 adopts a traditional hollow br...

Embodiment 2

[0062] The present embodiment is the construction technology of embodiment 1, specifically comprises the following steps:

[0063] Step 1, welding the steel frame 16; prepare 2 steel square tubes 1 with the same structure and 7 angle steels 2 with the same structure, weld the angle steel 2 between the two steel square tubes 1, and open positioning holes on the horizontal plane 3 of the angle steel 2 5;

[0064] Step 2, making pottery bricks with holes 6; opening mutually symmetrical positioning holes 5 on the upper and lower end faces of the pottery bricks;

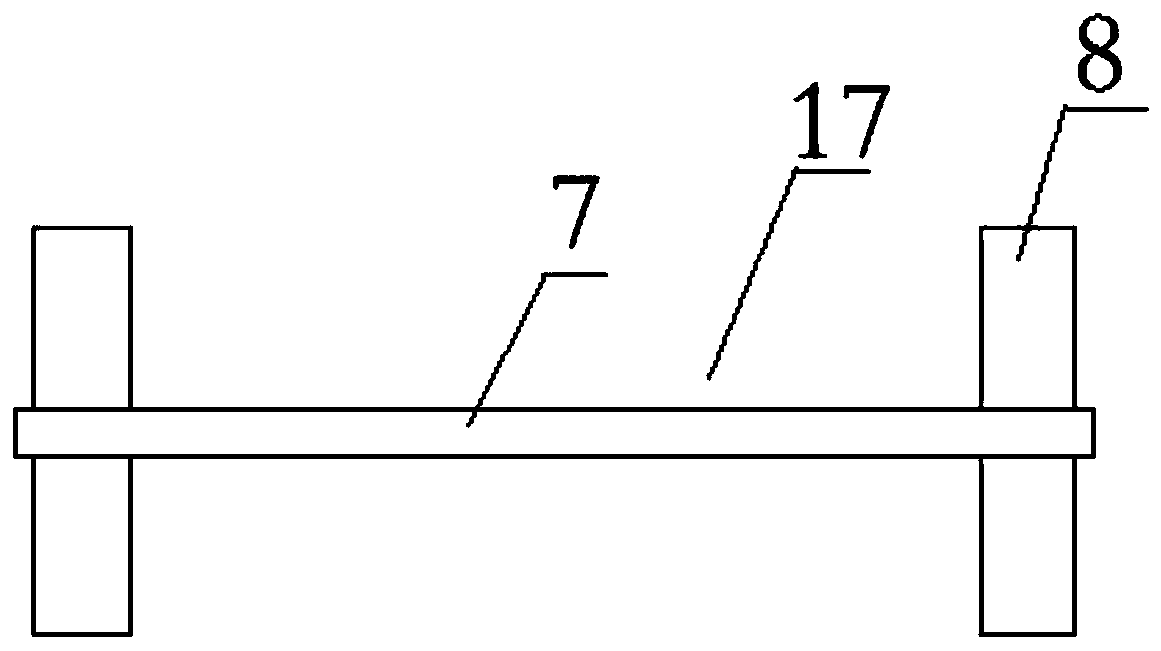

[0065] Step 3, making a positioning structure 17; the positioning structure 17 includes a nylon gasket 7 and a positioning pin 8, and the positioning pin 8 is arranged on both sides of the nylon gasket 7;

[0066] Step 4, making the prefabricated unit wall 15; placing the nylon gasket 7 of the positioning structure 17 on the horizontal plane 3 of the angle steel 2 below, and inserting the positioning pin 8 of the lower e...

Embodiment 3

[0071] Such as Figure 6-Figure 9 As shown, this embodiment provides an adjustable ceramic brick dry-hanging device, including a Hafen trough embedded part 13, a steel support 14 and a prefabricated unit wall 15, and the Hafen trough embedded part 13 is embedded in a building One side of the notch inside the wall body 12 is exposed for connecting with the steel support 14 .

[0072] Such as Figure 10 As shown, the steel support 14 includes a T-shaped bolt 18, a steel bracket 19, an adapter frame 20, a square column 21 and a connecting column 23, and the head of the T-shaped bolt 18 is buckled into the embedded part of the Hafen groove 13 in the C-shaped groove. The steel bracket 19 is a cuboid structure, one side of which is fixedly connected to the embedded part 13 of the Hafen groove through T-shaped bolts 18, and the front and rear positions of the prefabricated unit wall 15 are adjusted by adjusting the position of the T-shaped bolt 18 in the C-shaped groove. Adjustmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com