Power device thermal protection and early warning method and system based on junction temperature prediction

A power device, thermal protection technology, applied in the direction of automatic disconnection emergency protection device, emergency protection circuit device responding to undesired changes, emergency protection circuit device, etc. Reduce work efficiency, increase system cost, etc., to achieve the effect of improving stability and work efficiency, improving quality, and overcoming the lag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In one or more embodiments, a method for thermal protection and early warning of power devices based on junction temperature prediction is disclosed, including the following process:

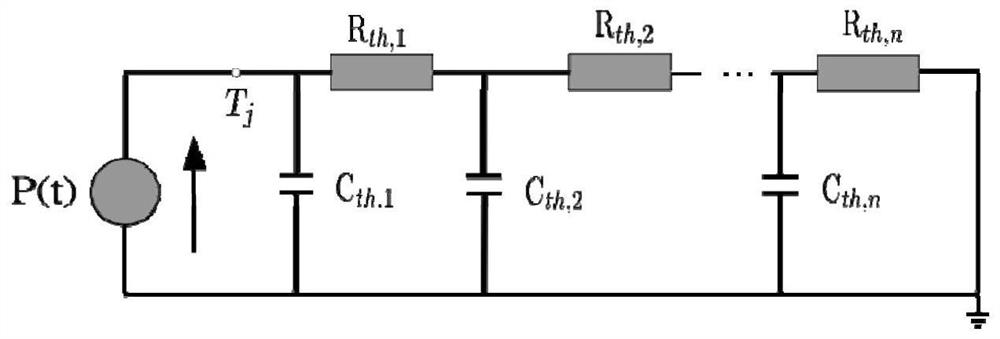

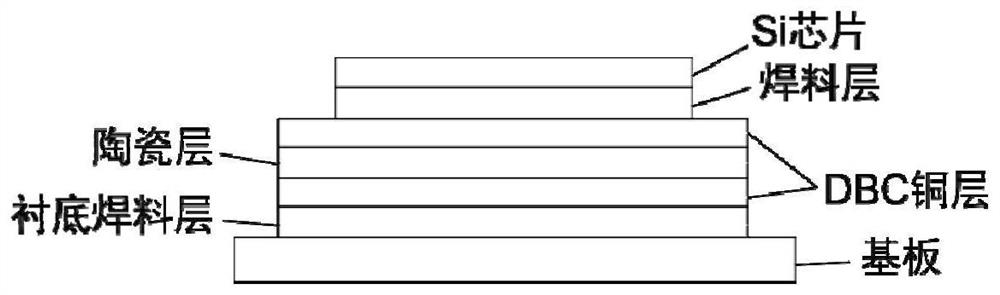

[0039] Calculate the thermal resistance and heat capacity corresponding to each layer inside the power device, and establish the corresponding Cauer thermal network model;

[0040] Establish a temperature model for the power device, and obtain the temperature inside the device through calculation. According to the state variable corresponding to the minimized cost function at n moments in the future, calculate the power consumption at n moments in the future, that is, the change trajectory of the heat flow parameter;

[0041] According to the Cauer thermal network model and the change trajectory of heat flow parameters, the junction temperature change trajectory of power devices is calculated;

[0042] Compare the calculated junction temperature change track with the warning temperature ...

Embodiment 2

[0056] In one or more embodiments, a power device thermal protection and early warning system based on power device junction temperature prediction is disclosed, including:

[0057] A device for calculating the thermal resistance and heat capacity corresponding to each layer inside the power device, and establishing the corresponding Cauer thermal network model;

[0058] A device for calculating the power consumption at n moments in the future, that is, the change track of the heat flow parameter, according to the state variables at n moments in the future corresponding to the minimized cost function;

[0059] A device for calculating the change track of the junction temperature of the power device according to the Cauer thermal network model and the change track of the heat flow parameter;

[0060] The device is used to compare the calculated junction temperature change track with the warning temperature to determine the current working state of the power device.

[0061] Th...

Embodiment 3

[0063] In one or more embodiments, a terminal device is disclosed, including a server, the server includes a memory, a processor, and a computer program stored on the memory and operable on the processor, and the processor executes the The program realizes the thermal protection and early warning method of the power device based on the junction temperature prediction in the first embodiment. For the sake of brevity, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com