Motor control method and device, electric vehicle and storage medium

A technology for motor control and electric vehicles, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of low system efficiency and low controller efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

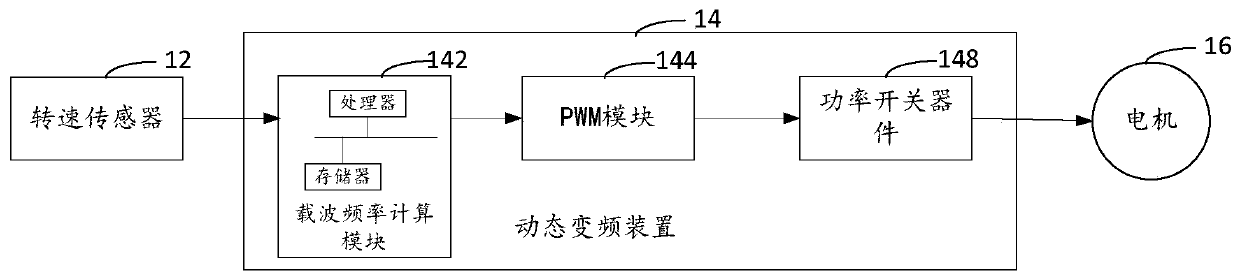

[0052] The motor control method provided by this application can be applied to such as figure 1 shown in the application environment. Wherein, the rotation speed sensor 12 is used to collect the rotation speed value of the motor, and transmit the collected current rotation speed value to the dynamic frequency conversion device 14 . The carrier frequency calculation module 142 of the dynamic frequency conversion device 14 can use the preset carrier frequency calculation model to calculate the triangular carrier frequency value (hereinafter referred to as the target carrier...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap