Method of inductively igniting a chemical reaction

A technology of reaction and phase reaction, applied in chemical instruments and methods, chemical methods for reacting gas medium with gas medium, inorganic chemistry, etc., can solve problems such as incomplete reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

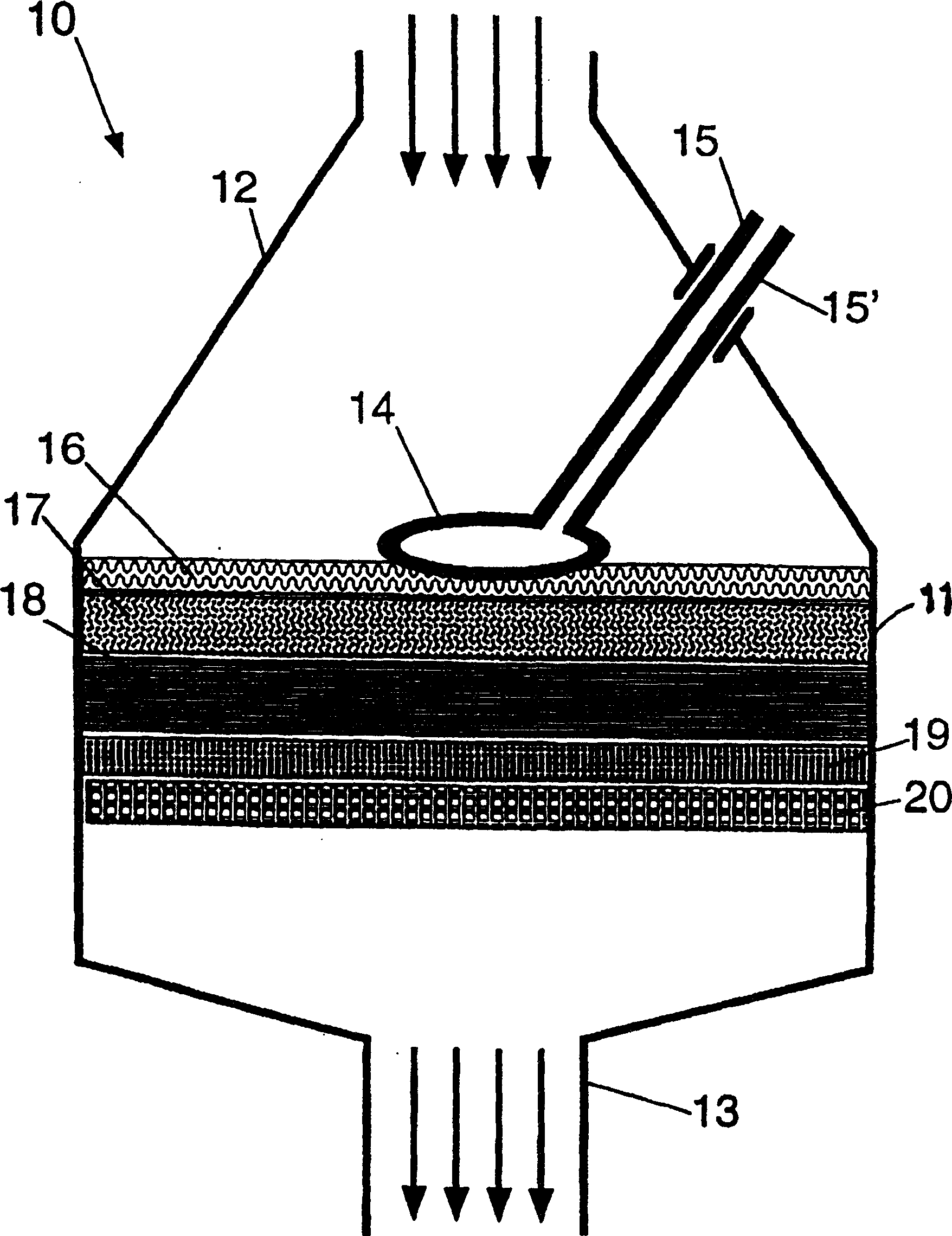

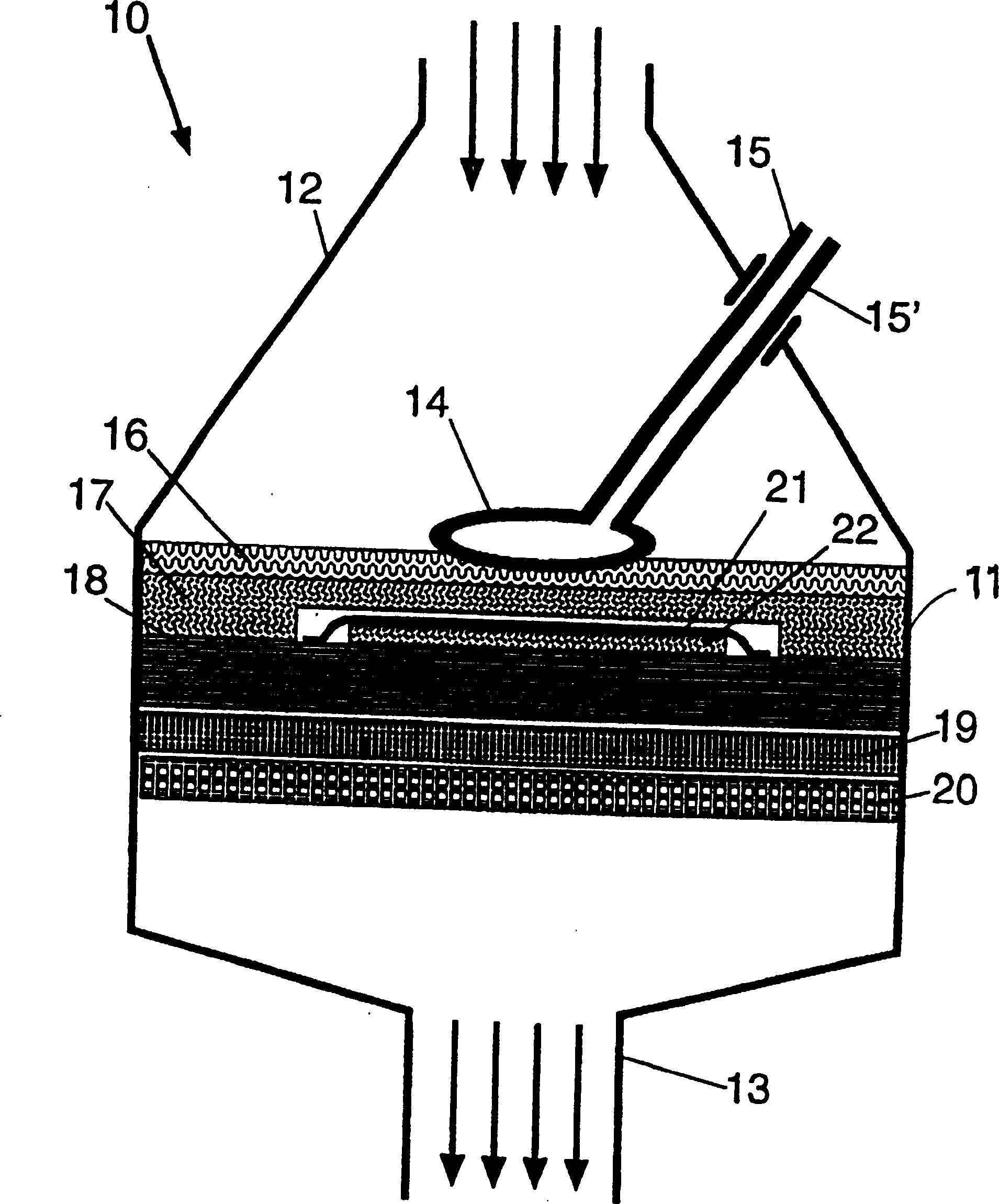

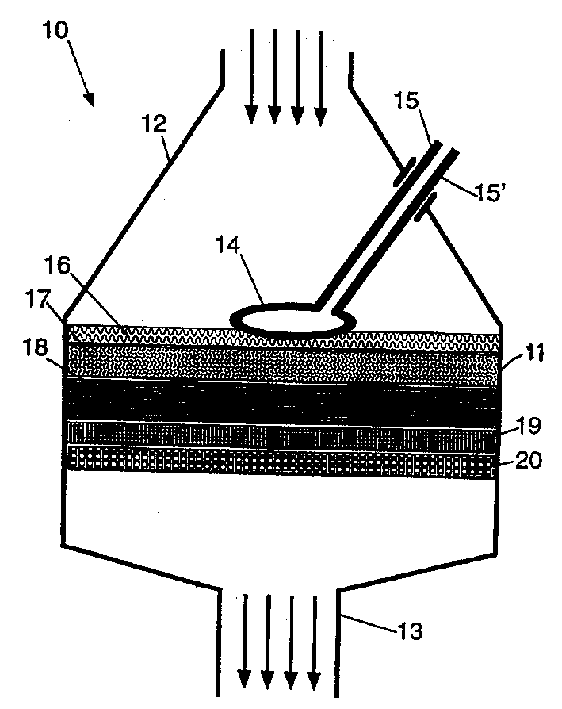

[0043] A laboratory scale 2 inch (5.08 cm) diameter quartz reactor was fabricated and tested for the purpose of evaluating the practicality of igniting reactions with built-in copper inductors. The reactor consists of a single coil of copper, a 3 / 16 inch (0.476 cm) thick ceramic foam catalyst support, 40 layers of platinum mesh and a final 3 / 16 inch (0.476 cm) thick ceramic foam catalyst support . The induction frequency is 26MHz. Several tests were carried out in order to evaluate the ignition, power input and to check whether the presence of copper rings inside the reaction chamber had a negative effect, with the following results:

[0044] Flow Ignition NH 3 CH 4 Air power time 1.26L / min 1.16L / min 6.67L / min 200Watts ~85sec.1.26L / min 1.16L / min 6.67L / min 250Watt ~40sec.1.26L / min 1.16L / min 6.67L / min 300Watts ~20sec .1.26L / min 1.16L / min 6.67L / min 350Watts ~10sec.

[0045] As can be seen from the table above, ignition is achieved in about 10 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com