Reaction kettle with accurate temperature control

A reaction kettle, precise technology, applied in chemical/physical/physical chemical fixed reactor, chemical/physical/physical chemical process, chemical instrument and method, etc. Uniformity and other issues, to avoid uneven temperature distribution, uniform heating, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

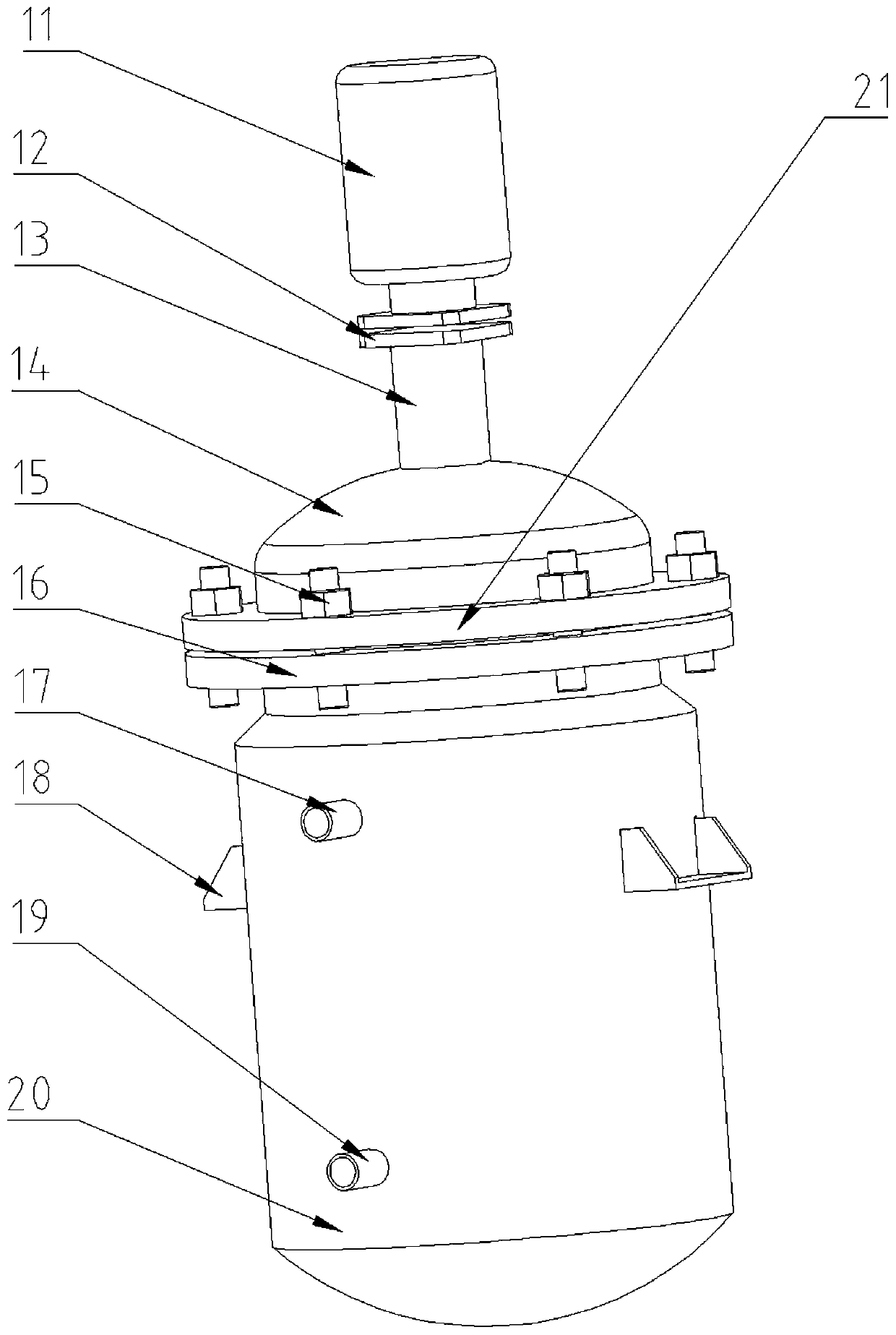

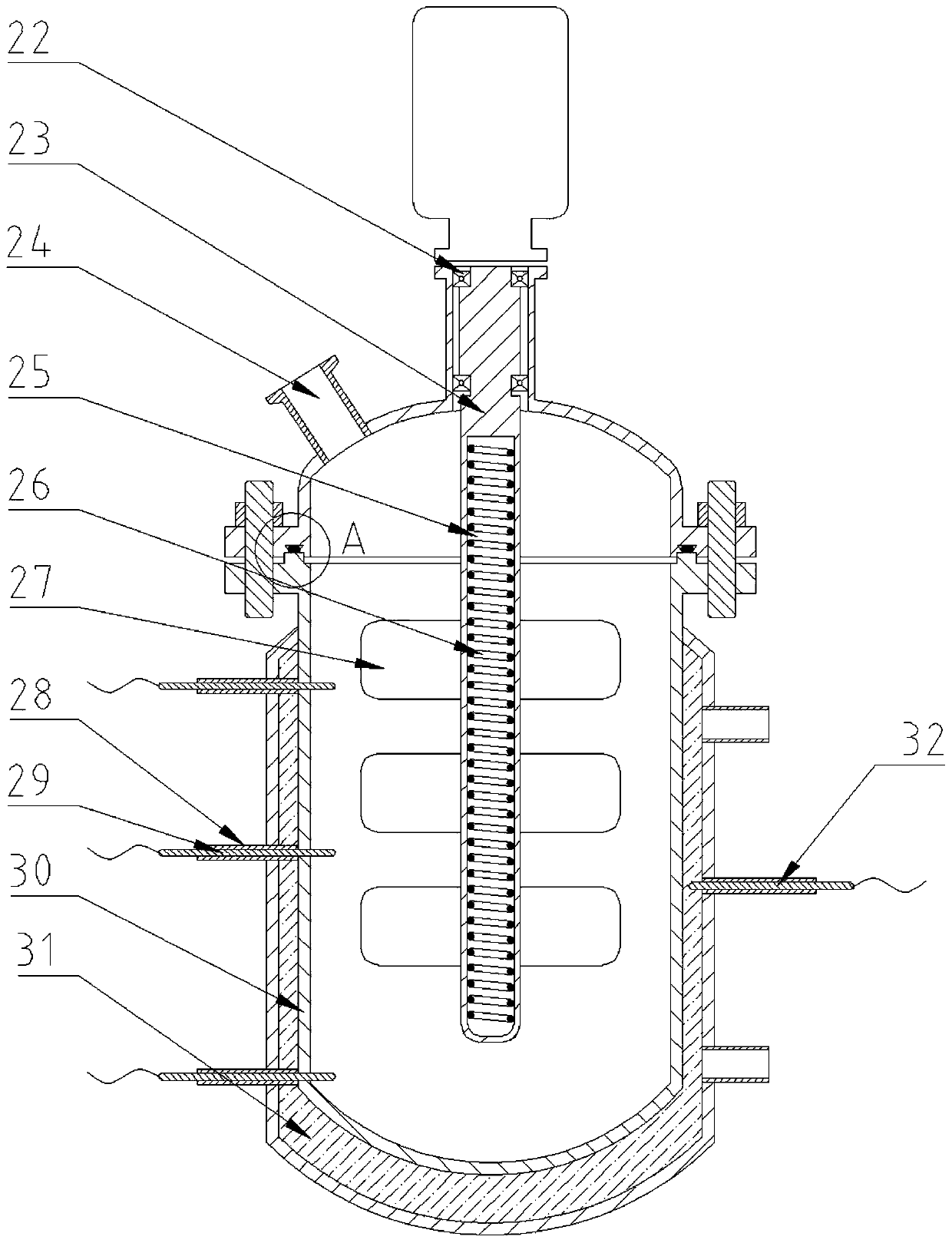

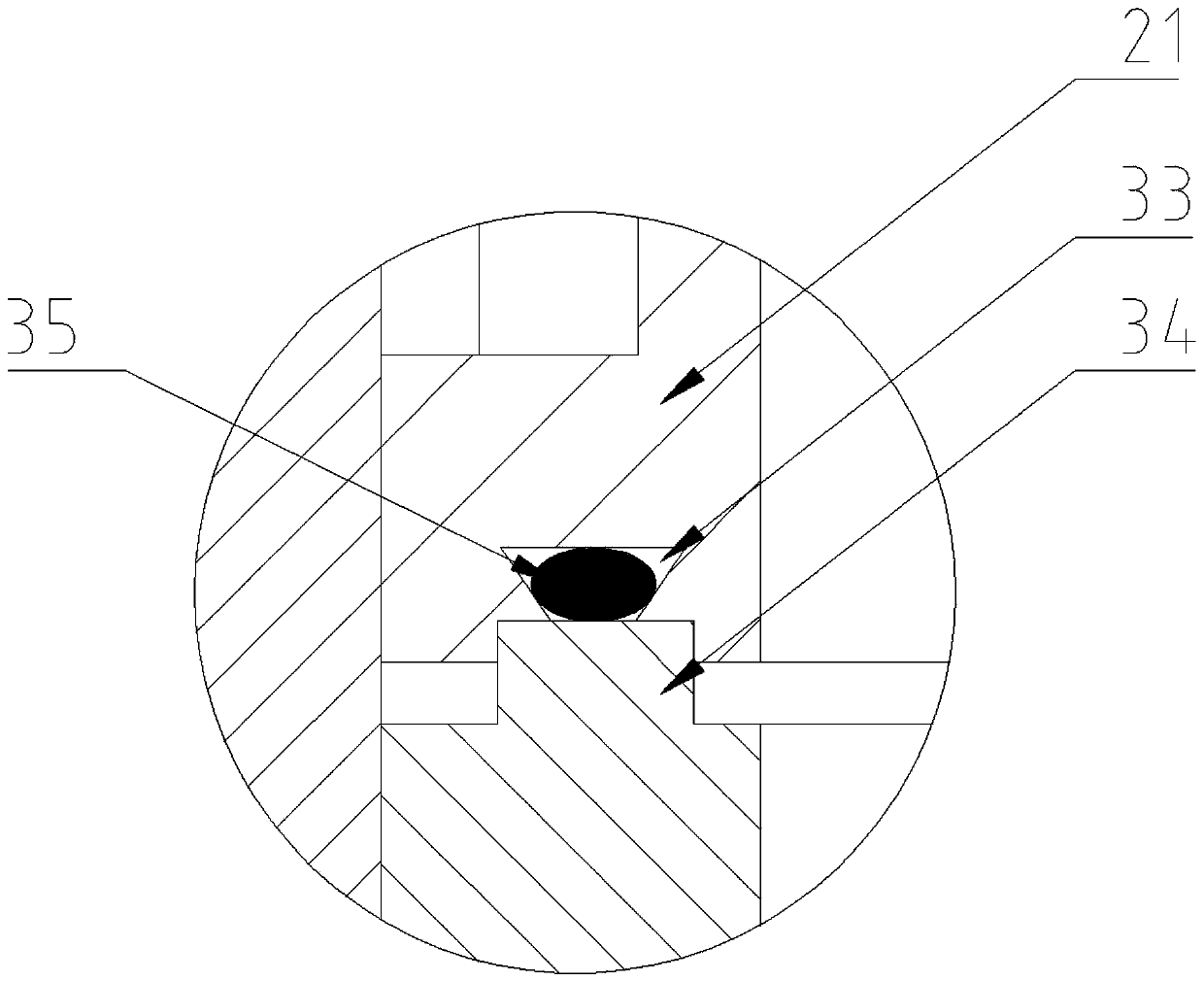

[0023] See Figure 1-3 , An accurate temperature control reactor, comprising a drive motor 11, a bearing seat 13, a rotating shaft (23), a stirring paddle (27) and a kettle body (30), the kettle body (30) is a hollow cylinder Shaped cylinder, the bottom of which is fixedly connected to a hemispherical head with straight edges, the upper part of the main body (30) is fixedly connected with a body flange (16), and the upper part of the body flange (16) A threaded hole matched with the bolt is opened, and an upper cap 14 of the autoclave is arranged above the main body (30) of the autoclave, and the upper cap 14 of the autoclave has a hemispherical shape as a whole and is fixedly connected to the bottom of the autoclave. A head flange (21), the head flange (21) is provided with a through hole matching the bolts, and the head 14 on the kettle body and the kettle body (30) pass between The fastening component (15) realizes a detachable connection. The fastening component (15) inclu...

Embodiment 2

[0029] This example is a further limitation and improvement of Example 1 on the basis of Example 1. A temperature-controlled reactor includes all the technical features in Example 1. In addition, as a further solution of this example : In order to facilitate the support and fixation of the kettle body (30) in this embodiment, two supports (18) are arranged on the side wall of the heating jacket (20), the supports (18) are symmetrical It is arranged on both sides of the heating jacket (20) and is fixedly connected to the heating jacket (20).

[0030] As a further solution of this embodiment: in order to improve the accuracy of temperature measurement in this embodiment and to measure the temperature of materials at different positions, there are three temperature measuring elements (29), which are evenly and equidistantly arranged on the heating The left side of the jacket (20).

[0031] As a further solution of this embodiment: the temperature measuring element (29) and the jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com