Embedded electromagnetic multi-vertical-ring high-gradient magnetic separator

A high-gradient magnetic separator, embedded technology, applied in the direction of high-gradient magnetic separator, magnetic separation, solid separation, etc., can solve the problems of low sorting efficiency and high operating cost, so as to improve the sorting efficiency and processing capacity , The effect of improving the beneficiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

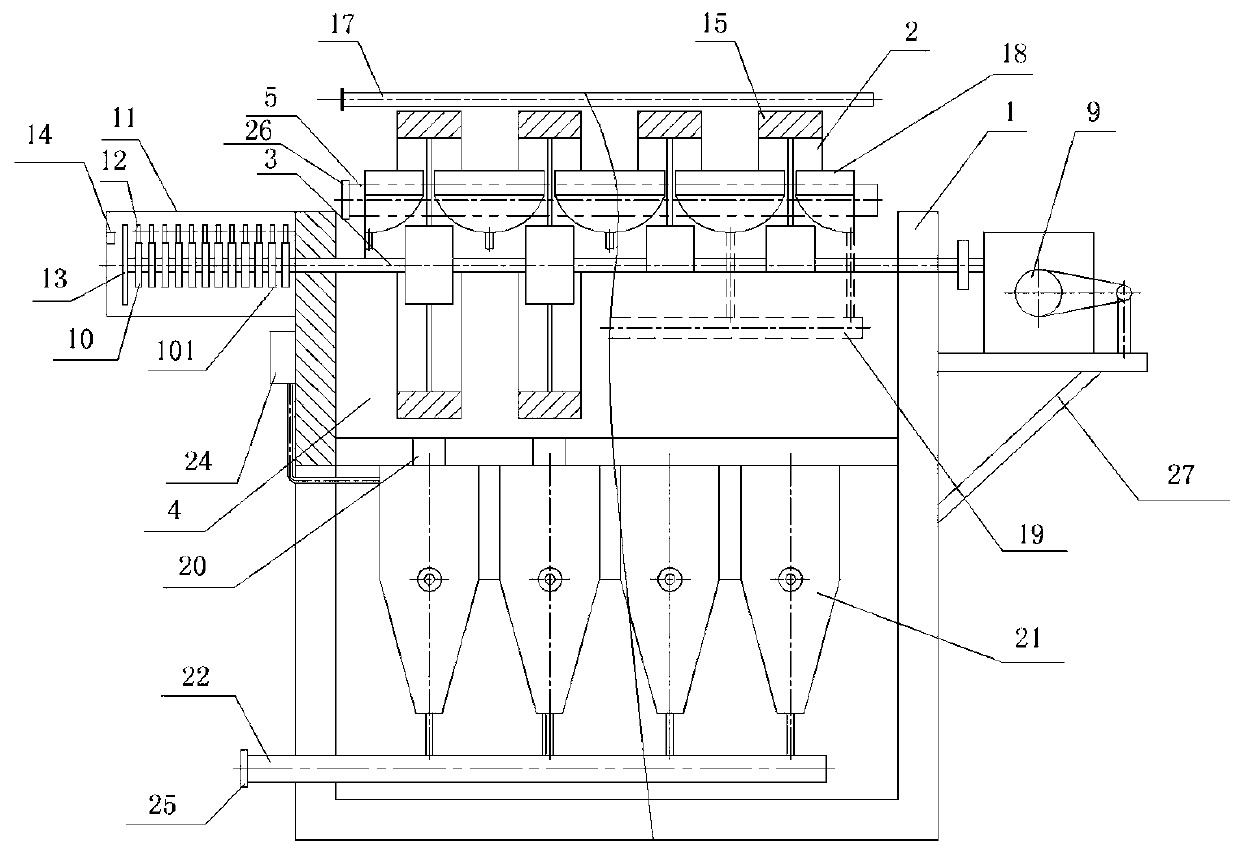

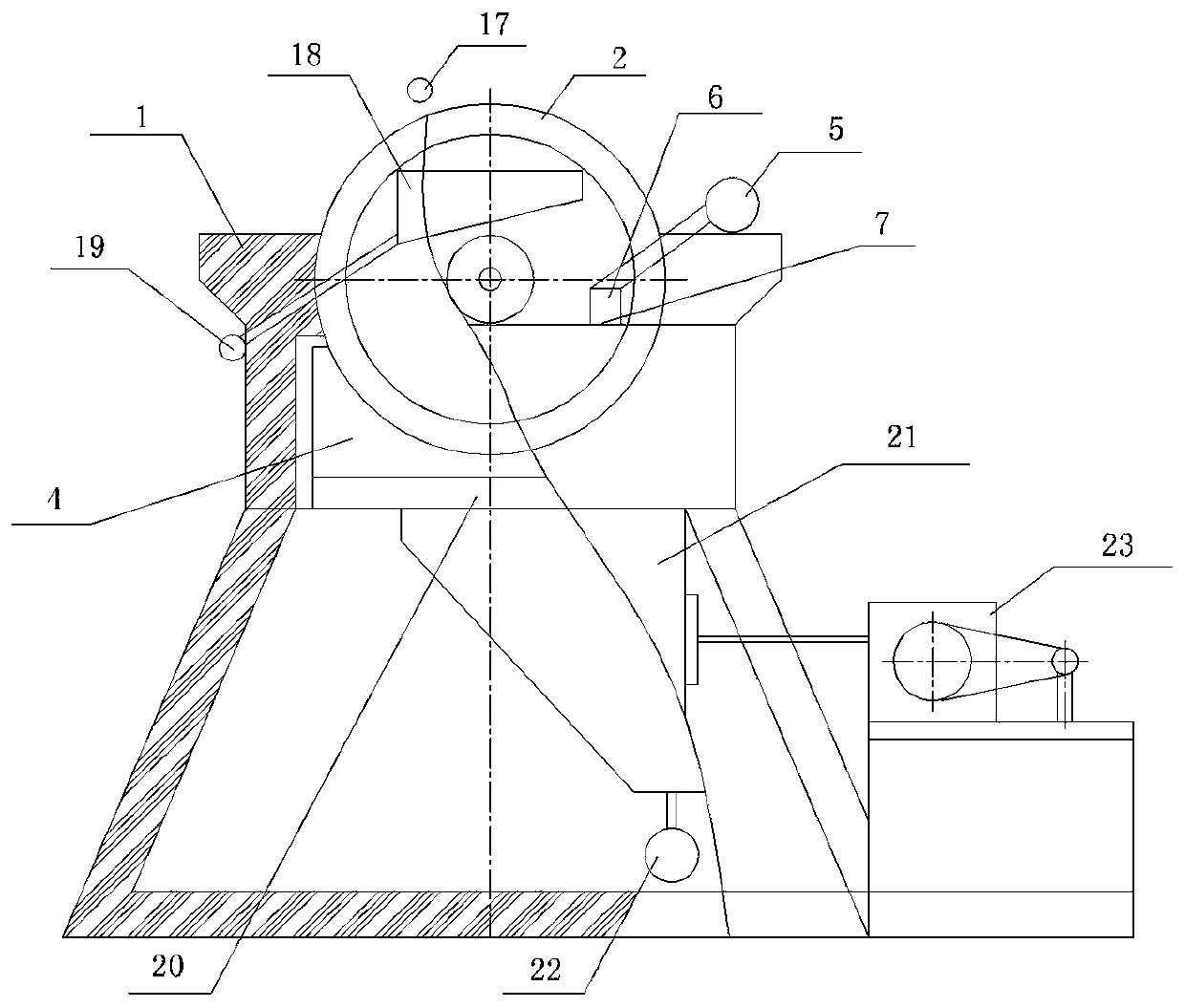

[0034] see Figure 1 to Figure 4 , an embedded electromagnetic multi-ring high-gradient magnetic separator, comprising a frame 1, four sorting vertical rings 2, a hollow main shaft 3, and a controller. The upper part of the frame 1 is provided with a beneficiation chamber 4, the feeding pipe 5 is connected with the feeding hopper 6, and the outlet 7 of the feeding hopper 6 is directly above the beneficiation chamber 4, and the ore pulp flows through the feeding pipe 5 and the feeding hopper 6 in turn. Into the dressing chamber 4.

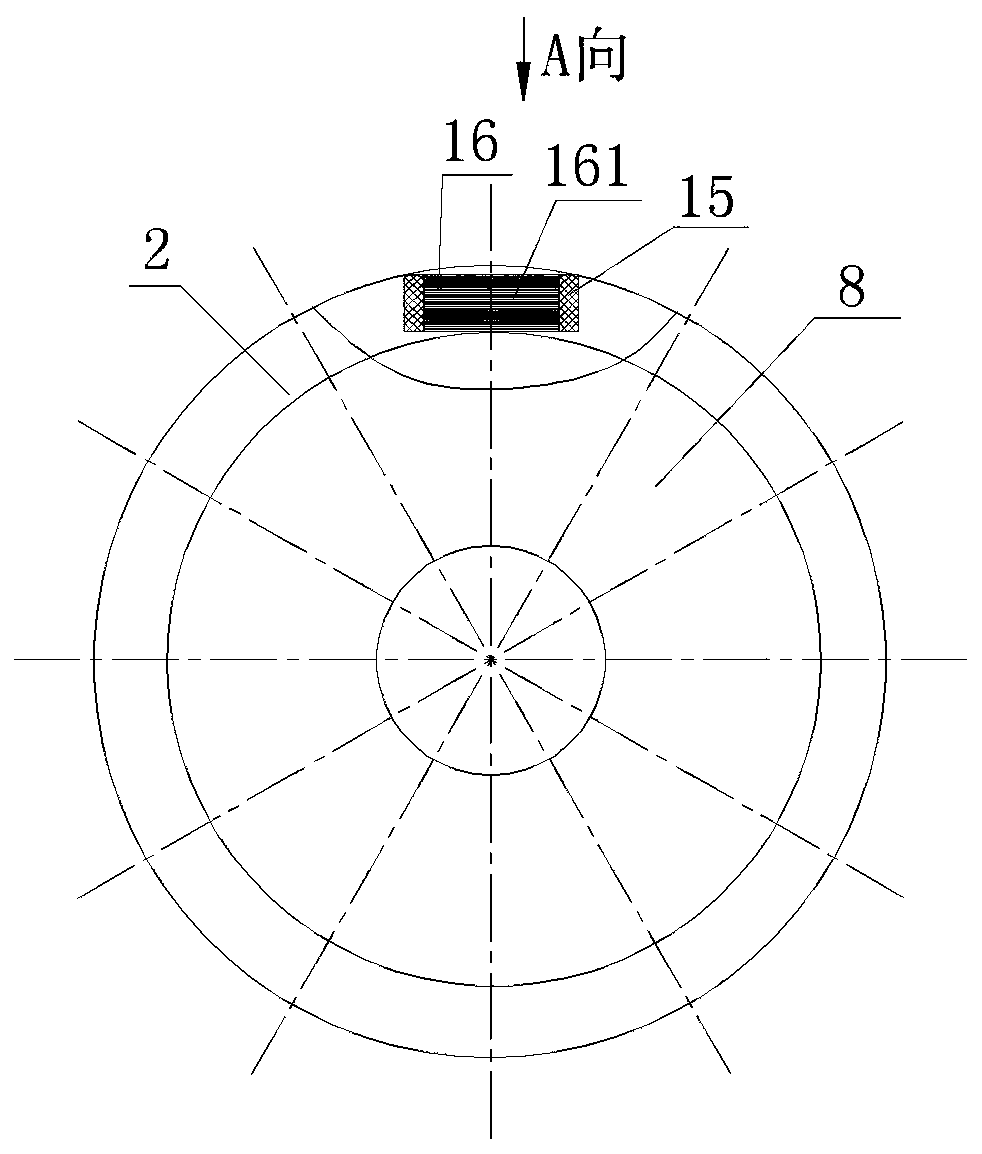

[0035] Specifically, the four sorting vertical rings 2 are vertically installed on the hollow main shaft 3 parallel to each other through the webs 8 . The two ends of the hollow main shaft 3 run through the two sides of the upper part of the frame 1 respectively, the lower part of the separation vertical ring 2 is in the beneficiation chamber 4, and one end of the hollow main shaft 3 through the frame 1 is connected with the separation vertical rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com