Feeding and conveying mechanism of fruit optimization equipment

A fruit and feeding technology, applied in sorting and other directions, can solve the problems of low transmission efficiency, unstable performance, and high requirements for working space, and achieve the effects of intelligent adjustment of feeding speed, stable work, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

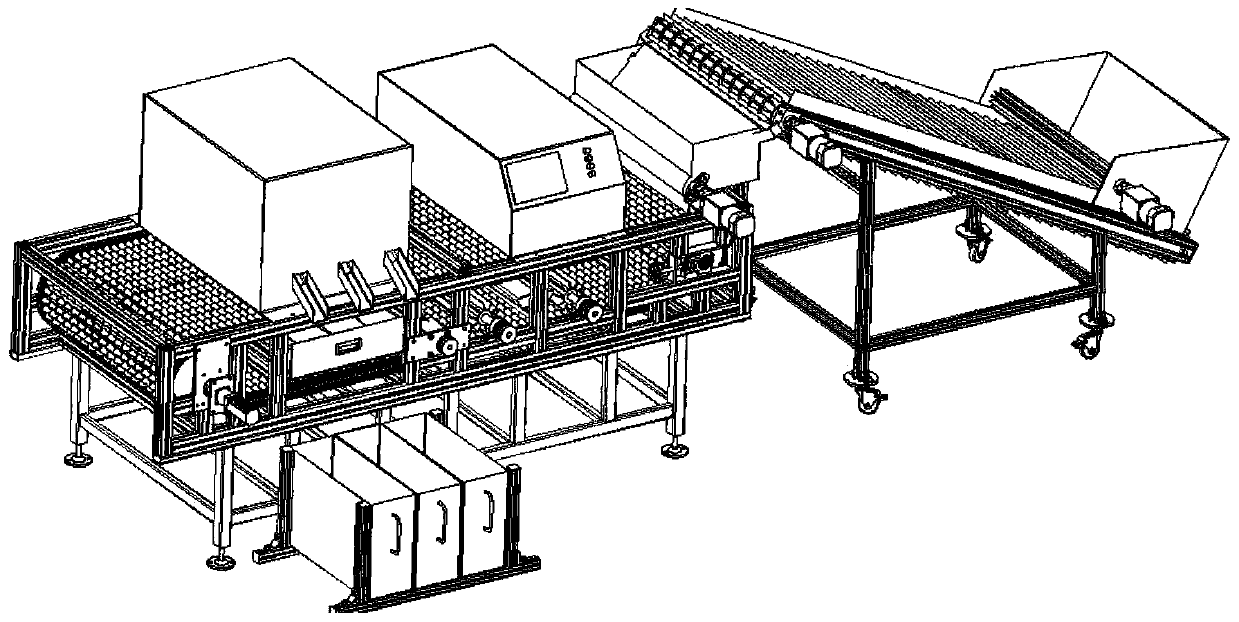

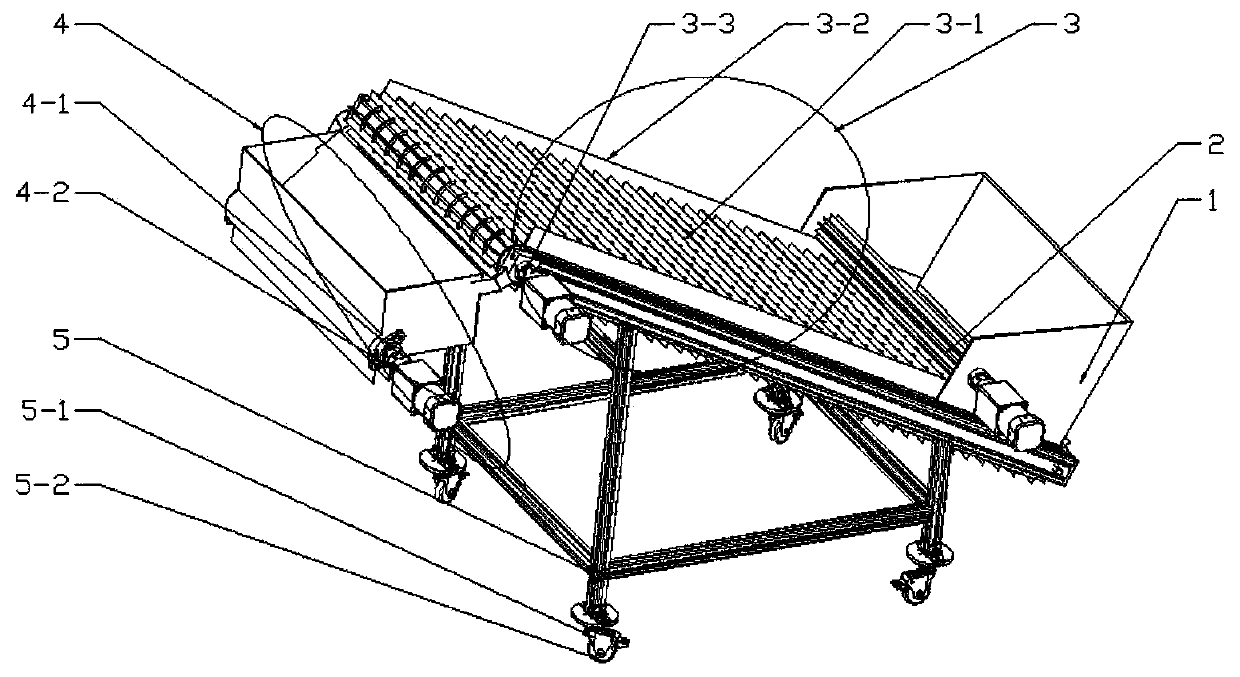

[0019] The following will be combined with the attached Figure 1-7 , taking jujube and other fruits as examples to describe the feeding mechanism. Depend on figure 1 and 2 , The fruit optimization equipment is composed of a feeding conveying device, a horizontal conveying device, a detection device, a pneumatic mechanism, a screening device, and a collection box. The feeding conveying device adopts the mode of inclined feeding, and the conveyer belt (3) is co-located with the feeding support (5), and the inclination angle of the conveyer belt can be changed by adjusting the height of the lower side support feet of the support frame (5-3). Fruits such as jujube are poured in the space that is formed by retaining plate (1) and height-limiting hairbrush (2), and transmission motor (3-4) controls power transmission shaft (3-3) to drive conveyor belt (3) and starts to rotate. The baffle plate (1) prevents red dates and other fruits from slipping off the conveyor belt (3) during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com