Flower basket pressing rod automatic mounting system

An automatic installation and flower basket technology, which is applied in the field of solar cells, can solve problems such as potential safety hazards, and achieve the effects of preventing falling off, improving work efficiency, and preventing shaking and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

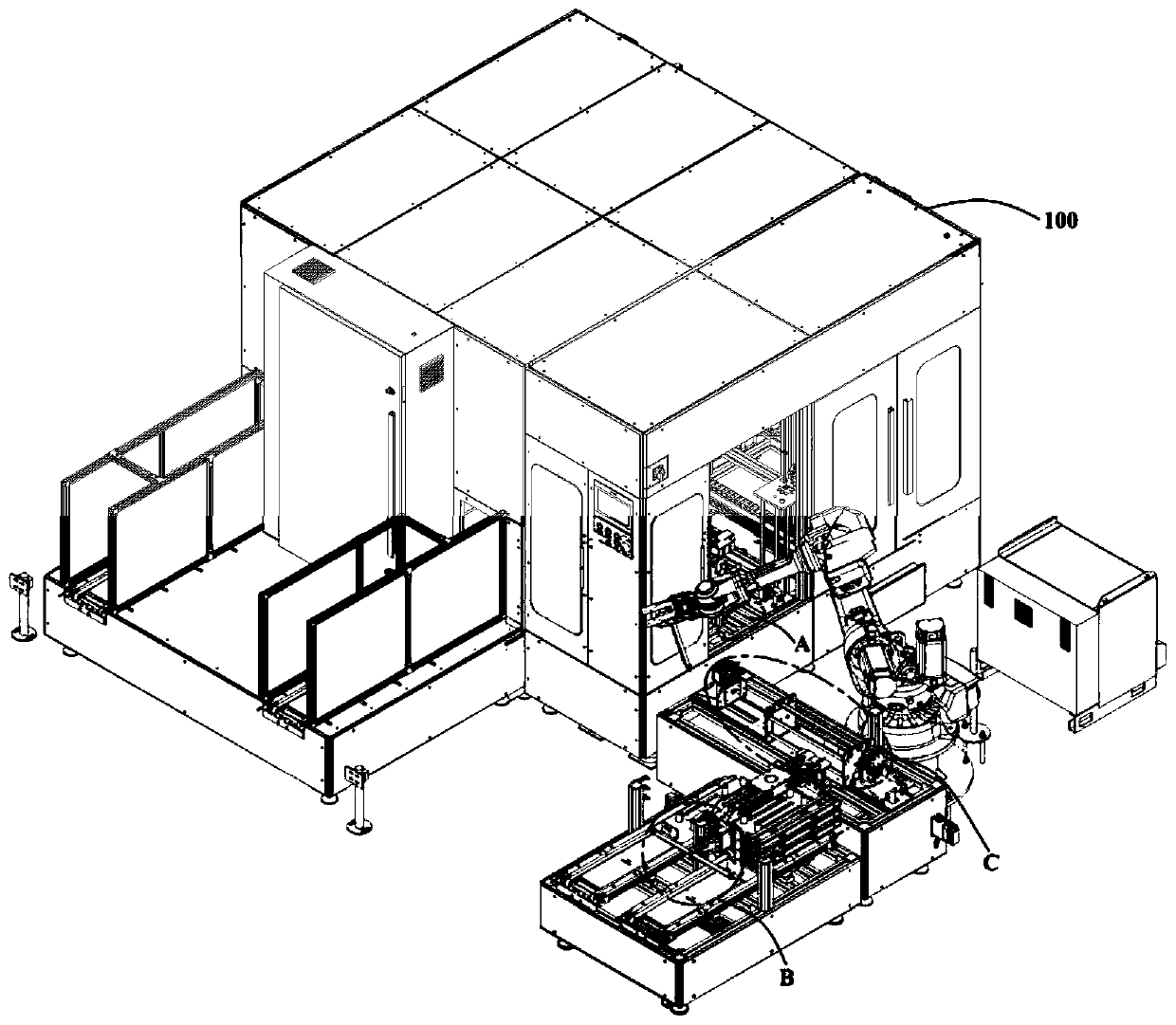

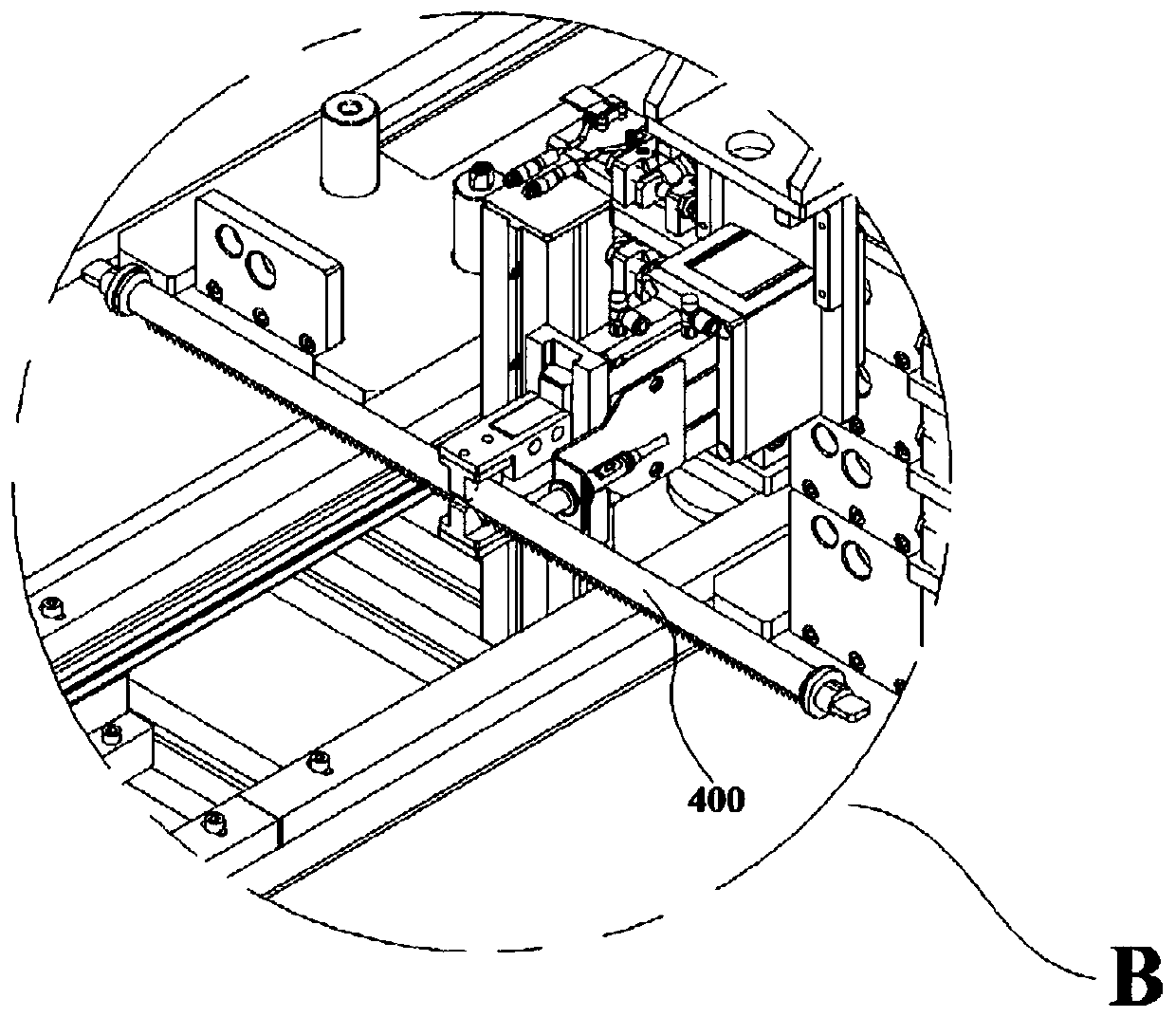

[0042] combine Figure 1 to Figure 3 , an automatic installation system for flower basket pressing bars in this embodiment, including a frame 100, a clamping mechanism 200 and an assembly mechanism 300, the clamping mechanism 200 is used to clamp flower baskets 500 and flower basket pressing bars 400, and the flower baskets 500 and The flower basket pressing rod 400 is installed on the assembly mechanism 300 , and finally the flower basket pressing rod 400 restricts the silicon wafer in the flower basket 500 .

[0043] In this embodiment, the frame 100 is provided with a device for loading the flower basket with silicon wafers. When the flower basket is full of silicon wafers, input relevant commands to control the robot to move the clamping mechanism 200 to the flower basket handling station A in the frame 100. The flower basket 500 is clamped, and the clamping mechanism 200 for clamping the flower basket 500 is moved by the robot from the flower basket handling station A to ...

Embodiment 2

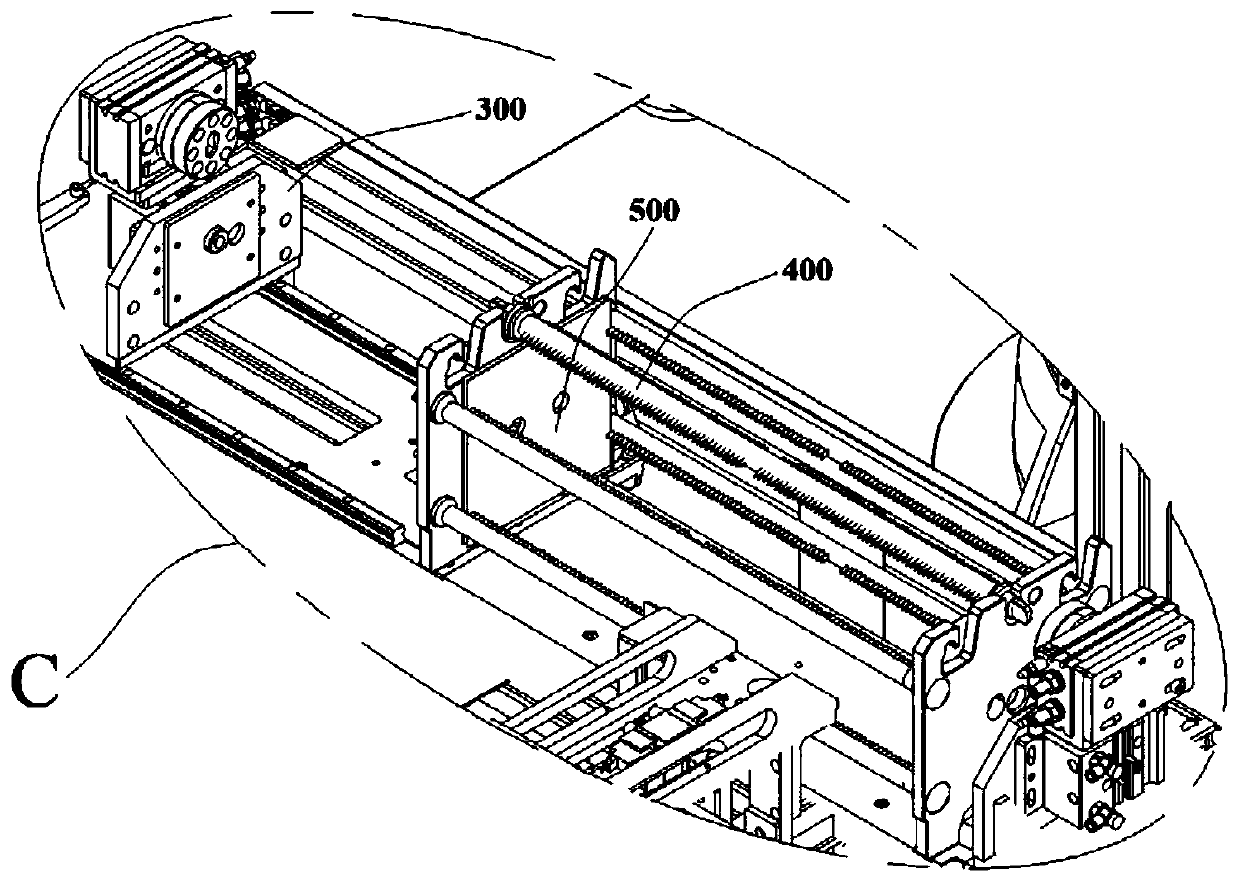

[0051] combine Figure 8 , an automatic installation system for flower basket pressing rods in this embodiment, its structure is basically the same as that of Embodiment 1, furthermore, a lifting cylinder 321 is provided on the mounting base 320 in this embodiment, and the lifting cylinder 321 is used to drive the pressing rod fixing mechanism 323 lifts along the height direction of the flower basket 500. Further, the mounting base 320 is also provided with a rotating cylinder 322 for driving the pressing rod fixing mechanism 323 to rotate, and the rotating cylinder 322 is driven up and down by the lifting cylinder 321 .

[0052] Specifically, the pressing bar fixing mechanism 323 in this embodiment is a cylindrical structure, one end of the pressing bar fixing mechanism 323 is fixedly connected with the rotating cylinder 322 , and the center hole 324 for fixing the basket pressing bar 400 is opened in the center of the other end.

[0053] combine Figure 9 Specifically, in ...

Embodiment 3

[0058] An automatic installation system for flower basket pressing rods in this embodiment has basically the same structure as Embodiment 1. Preferably, in order to make the flower basket 500 placed stably on the assembly base plate 310, the guide slide rail 311 on the assembly base in this embodiment is along the The length direction of the flower basket 500 is arranged in sections, and the distance between the guide rails 311 is not less than the length of the flower basket 500 .

[0059] Specifically, in this embodiment, the guide rail 311 is divided into left and right sections, and the opposite ends of the guide rail 311 are provided with flower basket positioning blocks 314 , and the flower basket positioning blocks 314 limit the flower basket 500 . When the robot carries the flower basket 500 from the flower basket handling station A to the assembly station C, it can use the flower basket positioning block 314 as a reference to place the flower basket 400 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com