Method for treating industrial wastewater generated by papermaking

A treatment method and technology for industrial wastewater, applied in biological water/sewage treatment, water/sewage treatment, light water/sewage treatment, etc., can solve problems such as low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

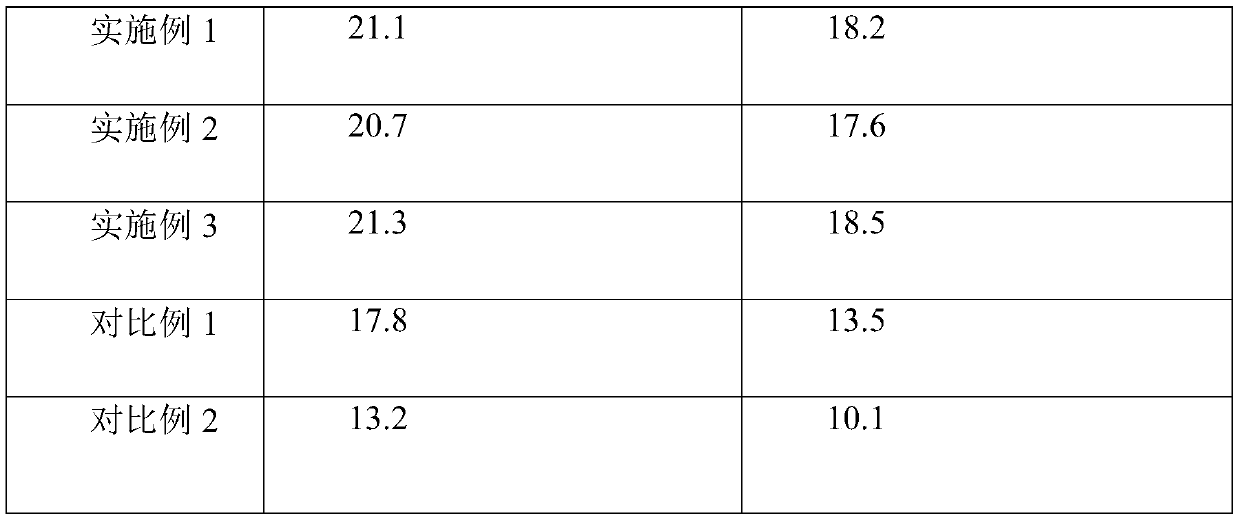

Embodiment 1

[0025] A kind of industrial wastewater treatment method that papermaking produces of the present embodiment comprises the following steps:

[0026] Step 1, accumulation of waste water: send the waste water generated from papermaking into the waste water tank for accumulation, then add activated composite bacteria into it, and then seal the tank with film for fermentation, the fermentation temperature is 35°C, and the fermentation is 4 days;

[0027] Step 2, primary filtration: the waste water fermented in step 1 is discharged into the primary filter pool, and activated carbon is added into the primary filter pool to filter and reduce precipitation;

[0028] Step 3, irradiation treatment: send the wastewater settled in step 2 into the light purification pool, add nano-titanium dioxide into the light purification pool, and then use ultraviolet rays and gamma rays for irradiation treatment in sequence;

[0029] Step 4, electrochemical treatment: irradiating ultraviolet rays and g...

Embodiment 2

[0036] A kind of industrial wastewater treatment method that papermaking produces of the present embodiment comprises the following steps:

[0037] Step 1, accumulation of waste water: send the waste water produced by papermaking into the waste water tank for accumulation, then add activated composite bacteria into it, and then seal the tank with film for fermentation, the fermentation temperature is 45°C, and the fermentation is 10 days;

[0038] Step 2, primary filtration: the waste water fermented in step 1 is discharged into the primary filter pool, and activated carbon is added into the primary filter pool to filter and reduce precipitation;

[0039] Step 3, irradiation treatment: send the wastewater settled in step 2 into the light purification pool, add nano-titanium dioxide into the light purification pool, and then use ultraviolet rays and gamma rays for irradiation treatment in sequence;

[0040] Step 4, electrochemical treatment: irradiating ultraviolet rays and gam...

Embodiment 3

[0047] A kind of industrial wastewater treatment method that papermaking produces of the present embodiment comprises the following steps:

[0048] Step 1, accumulation of waste water: send the waste water produced by papermaking into the waste water tank for accumulation, then add activated composite bacteria into it, and then seal the tank with film for fermentation, the fermentation temperature is 40°C, and the fermentation is 7 days;

[0049] Step 2, primary filtration: the waste water fermented in step 1 is discharged into the primary filter pool, and activated carbon is added into the primary filter pool to filter and reduce precipitation;

[0050] Step 3, irradiation treatment: send the wastewater settled in step 2 into the light purification pool, add nano-titanium dioxide into the light purification pool, and then use ultraviolet rays and gamma rays for irradiation treatment in sequence;

[0051] Step 4, electrochemical treatment: irradiating ultraviolet rays and gamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com