A metallic glass metamaterial with a wrinkled structure

A technology of metallic glass and metamaterials, applied in the direction of nanotechnology, can solve the problems of inability to apply structural parts, etc., and achieve the effects of inhibiting shear band propagation, superior energy absorption characteristics, and vibration weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

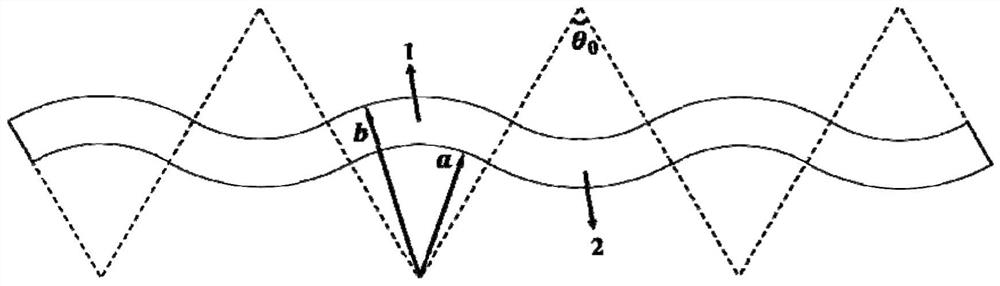

[0019] see figure 1 , the present invention includes a number of folded structures with the same size, consistent shape and periodic arrangement; Arc shape; the first ligament 1 and the second ligament 2 both include inner and outer surfaces, the shape of the inner surface and the outer surface is the same center, different radii, and the center angle is θ 0 The arc of the circle has radius a on the inside surface and radius b on the outside surface. The material of the corrugated structure is metallic glass.

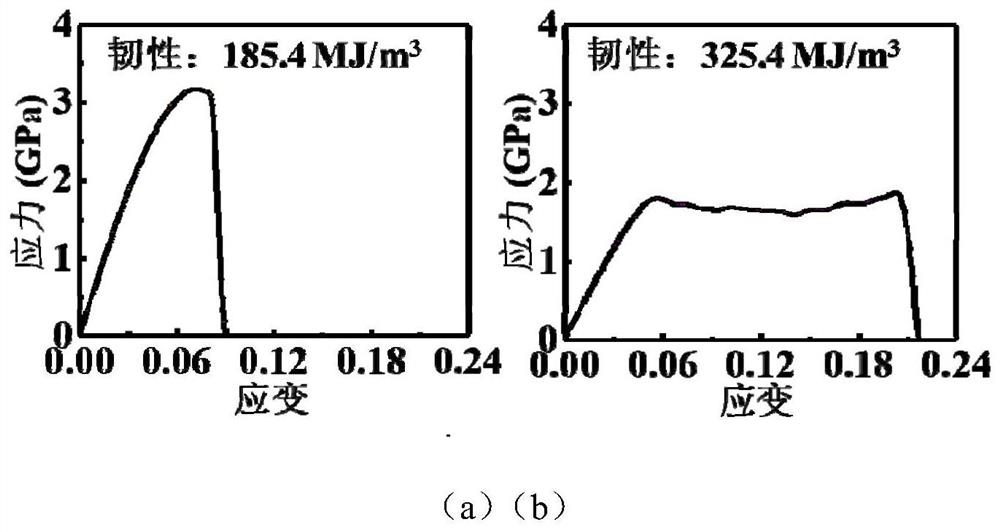

[0020] The invention combines the excellent mechanical properties of the metallic glass with the characteristics of the wrinkled structure itself, introduces the stress gradient from compression to tension through the structural design, and inhibits the propagation of the shear band, thereby greatly improving the room temperature plasticity of the metallic glass an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com